Freeze-dried facial mask containing fish scale collagen and preparation method of freeze-dried facial mask

A fish scale collagen and freeze-drying technology, which is applied to medical preparations containing active ingredients, skin care preparations, pharmaceutical formulas, etc., can solve the problems of many added ingredients, skin irritation, and complexity of the rejuvenating youth freeze-dried mask. Achieve the effect of rejuvenating healthy and supple skin, improving skin texture and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation of soluble collagen derived from marine fish scales is as follows:

[0023] (1) fish scales are cleaned and dried and soaked in 1% hydrochloric acid, continuously stirred for 24 hours, and the hydrochloric acid solution is replaced every 12 hours; (2) fish scales soaked in hydrochloric acid are rinsed three times with distilled water, then soaked in saturated sodium hydroxide solution, Stir continuously for 24 hours, and replace the sodium hydroxide solution every 12 hours; (3) Rinse the fish scales in (2) with distilled water until neutral, and then dry them in a 40°C electric constant temperature blast drying oven for 8 hours; (4) Use pulverized (5) The pulverized fish scale powder was continuously stirred in hot water at 60°C for 12h at a speed of 200rpm; (6) centrifuged at 4000rpm for 20min to collect the supernatant in (5), which was Fish scale collagen solution; (7) Freeze-drying the fish scale collagen solution to remove water to obtain pure fish ...

Embodiment 1~5

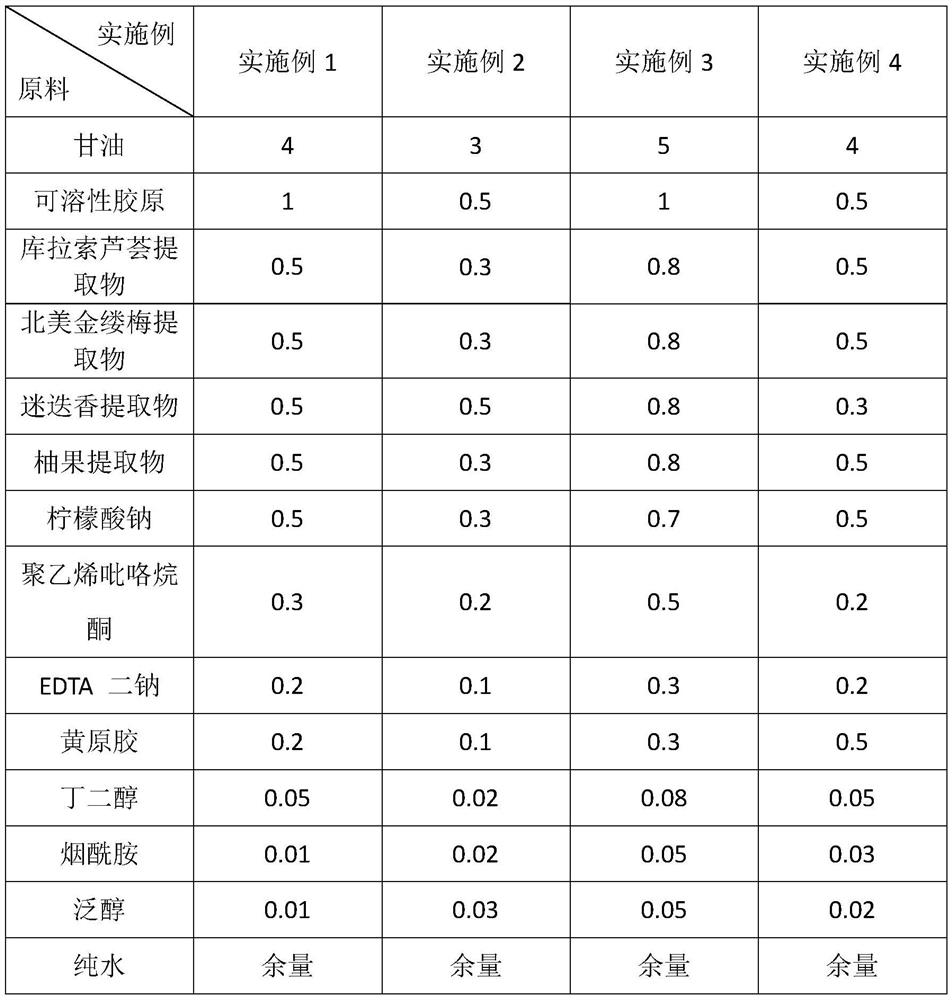

[0026] Table 1 The raw material composition (mass percentage %) of the freeze-dried facial mask containing fish scale collagen in each embodiment

[0027]

[0028] The preparation method of the freeze-dried facial mask containing fish scale collagen described in embodiments 1 to 4 is as follows: (1) moisturizer, antioxidant, skin conditioner, acidity regulator, antistatic agent, chelating agent, thickener are sequentially Add pure water and stir evenly to obtain a mixed solution; (2) fold the membrane cloth and place it on a tray, pour the mixed solution obtained in step (1) evenly into the membrane cloth in the tray to make a semi-finished product; (3) place the semi-finished product Freeze-dry in a vacuum freeze dryer, the method is as follows: pre-cooling at -20°C for 1 hour; after pre-cooling, vacuumize at -45°C for 2 hours to 0.2mbar; 10°C, each temperature gradient control time is 2h; (5) After the freeze-drying is completed, the product is sealed and packaged, and th...

Embodiment 5

[0036] The adsorption capacity of the membrane cloth used in the above-mentioned Examples 1 to 4 and Comparative Examples 1 to 3 to the facial mask liquid is tested, and the adsorption capacity is reflected by calculating the adsorption rate of the membrane cloth to the facial mask liquid. The details are as follows: Soak the membrane cloth in the mask solution for 10 minutes, then take out the membrane cloth and place it in the air for 1 minute, record the weight of the membrane cloth before and after soaking in the mask solution, and the calculation results of the adsorption rate are shown in Table 2 below:

[0037] group Example 1 Example 2 Example 3 Example 4 Adsorption rate(%) 1327±0.12 1072±0.12 1287±0.025 1198±0.15 group Comparative example 1 Comparative example 2 Comparative example 3 / Adsorption rate(%) 1259±0.16 1241±0.11 1119±0.05 /

[0038] The above results show that the natural plant fiber membrane cloth used in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com