Mud-resistant SHF2Mud (M type) sheath for NEK606 oil platform

An oil platform, mud-resistant technology, applied in cables, insulated conductors, conductors, etc., can solve the problems of cable sheath corrosion, shorten the service life of cables, etc., and achieve the effect of reducing service life, improving oil resistance, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

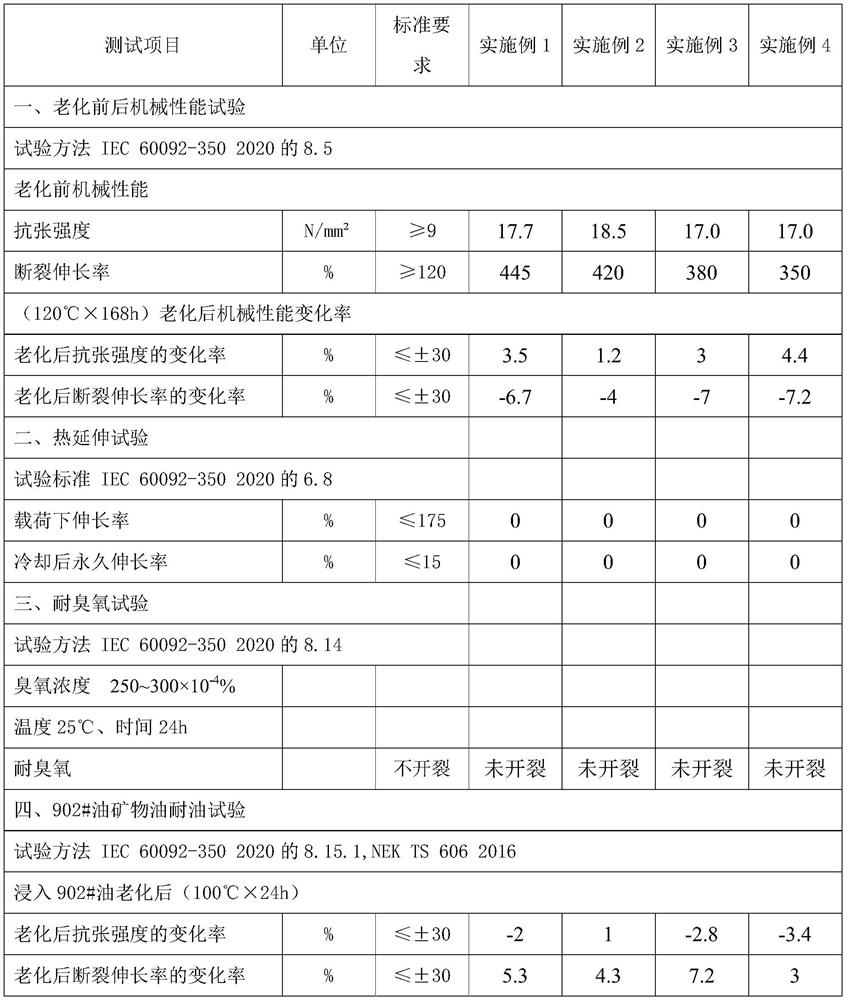

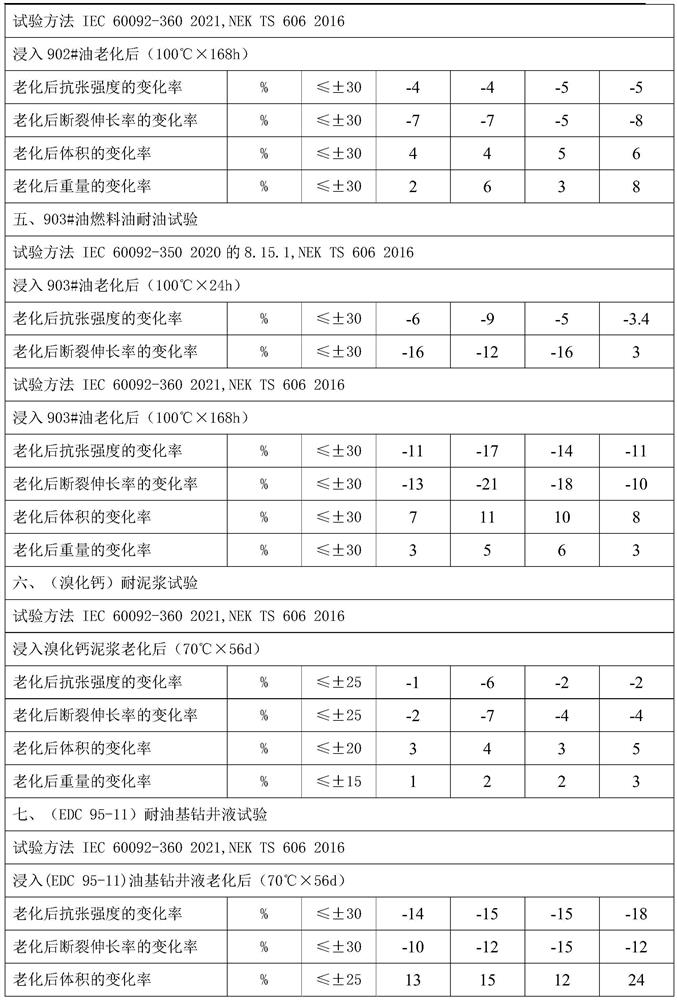

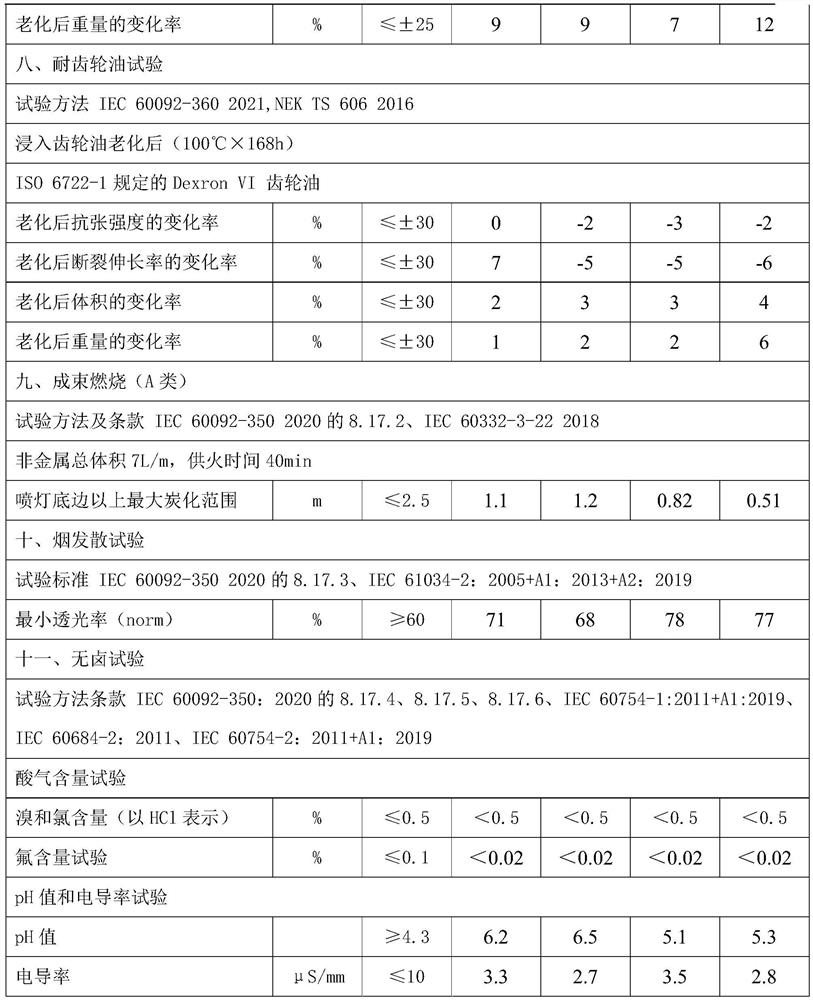

Examples

Embodiment 1

[0021] The mud resistant SHF2 Mud (M type) sheath of the NEK606 oil platform of the present embodiment comprises the component of following parts by weight:

[0022] 100 parts of HNBR, 1.5 parts of protective agent (RD and ZMB2), 5 parts of modified additive metal methacrylate, 15 parts of reinforcing agent (carbon black and white carbon black), 55 parts of compound flame retardant, reactive reinforcement 5 parts of plasticizer, 5 parts of metal oxide activator, 5 parts of peroxide curing agent.

[0023] In the HNBR, the acrylonitrile (ACN) content is 30% to 55%, the residual double bond content is 0 to 2%, and the Mooney viscosity ML1+4@100°C is 40 to 100, such as LANXESS German Lanxess fully saturated Therban A 4307, partially saturated Therban B3629, ZEON Japan Zetpol 1010L, Zetpol 2000L, etc.; the main glue used in this example is the 1:1 ratio of LANXESS Germany Lanxess fully saturated Therban A 4307 and partially saturated Therban B 3629 combination.

[0024] In the pr...

Embodiment 2

[0039] The NEK606 oil platform mud-resistant SHF2 Mud (M type) sheath of the present embodiment is the same as that of Embodiment 1, the difference is:

[0040] 100 parts of HNBR, 2.5 parts of protective agent (RD and ZMB2), 10 parts of modified additive zinc methacrylate, 22 parts of reinforcing agent (N330 carbon black and white carbon black), 55 parts of compound flame retardant, reactive reinforcement 5 parts of plasticizer, 5 parts of activator (ZnO+ stearic acid), 5 parts of vulcanizing agent.

[0041] In this embodiment, the composite flame retardant is ATH (aluminum hydroxide), MDH (magnesium hydroxide), and APP (ammonium polyphosphate).

[0042] The reactive plasticizer used in this embodiment is CTBN liquid hydroxybutyronitrile.

Embodiment 3

[0044] The NEK606 oil platform mud-resistant SHF2 Mud (M type) sheath of the present embodiment is the same as that of Embodiment 1, the difference is:

[0045]100 parts of HNBR, 1.5 parts of protective agent (RD and ZMB2), 15 parts of modified additive zinc methacrylate, 20 parts of reinforcing agent (N330 carbon black and white carbon black), 75 parts of compound flame retardant, reactive reinforcement 10 parts of plasticizer, 6.5 parts of activator (MgO+ stearic acid), 5 parts of vulcanizing agent.

[0046] In this embodiment, the main glue HNBR is the same as that in Embodiment 2.

[0047] In this embodiment, the composite flame retardant is APP (ammonium polyphosphate), MDH (magnesium hydroxide), and MCA (melamine cyanurate).

[0048] The reactive plasticizer used in this embodiment is HTBN liquid hydroxy-terminated butyronitrile.

[0049] The vulcanizing agent BIBP used in this embodiment is used in conjunction with TAIC (triallyl isocyanurate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com