Copolymer, preparation method thereof, aerogel composition and interface coating

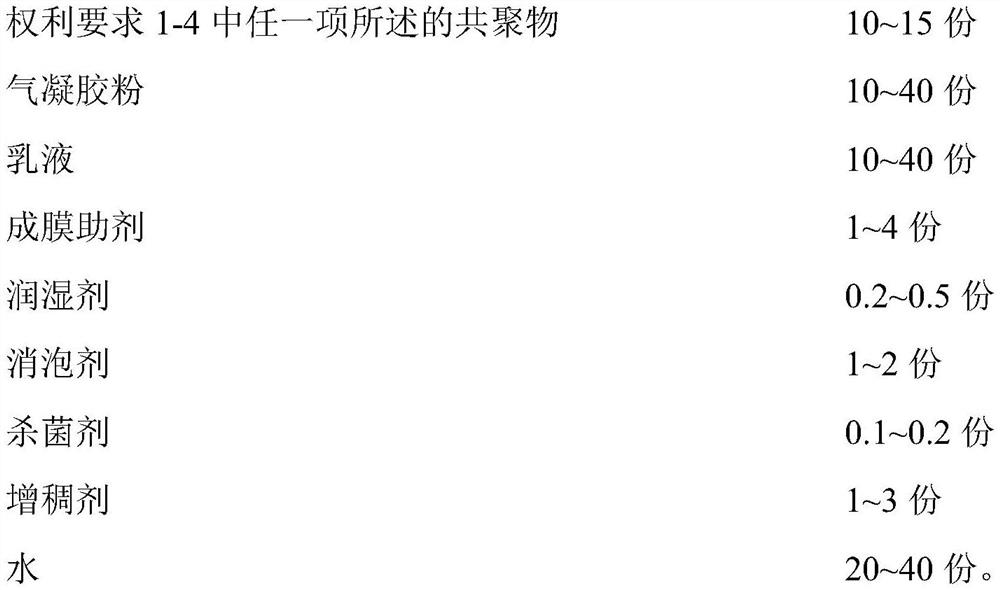

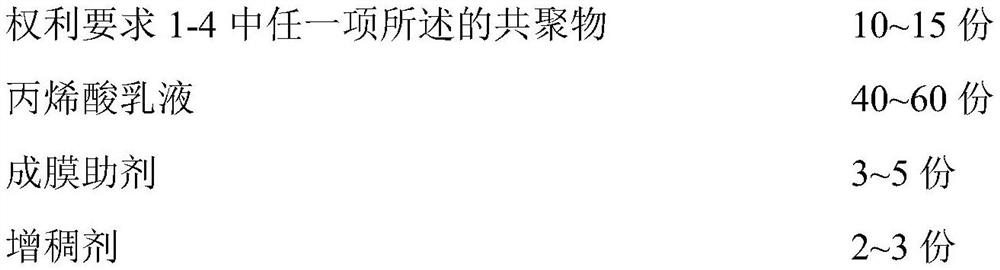

A technology of copolymer and aerogel, which is applied in the direction of coating, etc., can solve the problems of inability to improve the adhesion between substrates, weak interlayer bonding, and inability to add, so as to increase hydrophilicity and lipophilicity, and improve thermal insulation Effects of improving thermal performance and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

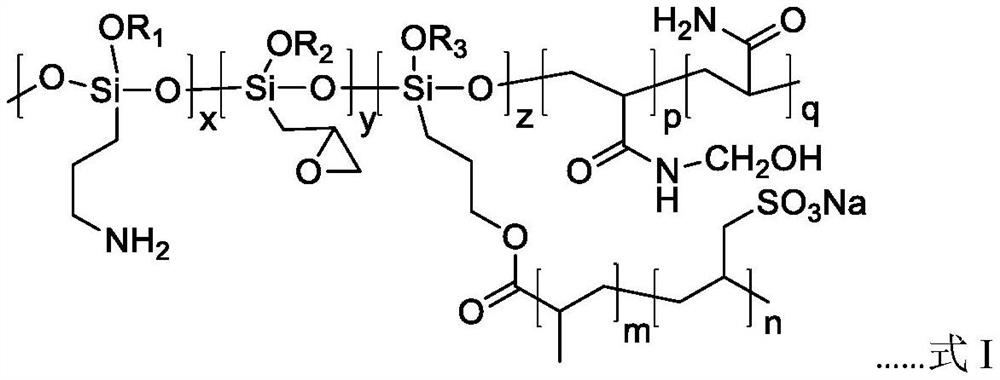

[0050] This embodiment provides a kind of copolymer, and this copolymer is prepared by the following method:

[0051] With the combination of hydrogen peroxide and tert-butyl hydroperoxide, the combination of white block and ascorbic acid, under the condition of double initiator, 60 parts of acryloxypropyl trimethoxysilane, 15 parts of epoxy silane 1. 25 parts of aminosilane reacted with 5 parts of sodium allyl sulfonate at a temperature of 40° C. to obtain a copolymer with a weight average molecular weight of 15,000.

Embodiment 2

[0053] This embodiment provides a kind of copolymer, and this copolymer is prepared by the following method:

[0054] With the combination of hydrogen peroxide and tert-butyl hydroperoxide, the combination of white block and ascorbic acid, under the condition of double initiator, 50 parts of acryloxypropyl trimethoxysilane, 10 parts of epoxy silane , 30 parts of aminosilane, at a temperature of 60° C., react with 8 parts of methylol acrylamide to obtain a copolymer with a weight average molecular weight of 20,000.

Embodiment 3

[0056] This embodiment provides a kind of copolymer, and this copolymer is prepared by the following method:

[0057] With the combination of hydrogen peroxide and tert-butyl hydroperoxide, the combination of white block and ascorbic acid, under the condition of double initiator, 80 parts of acryloxypropyl trimethoxysilane, 20 parts of epoxy silane 1. 20 parts of aminosilane are reacted with 10 parts of acrylamide at a temperature of 50° C. to obtain a copolymer with a weight average molecular weight of 5000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com