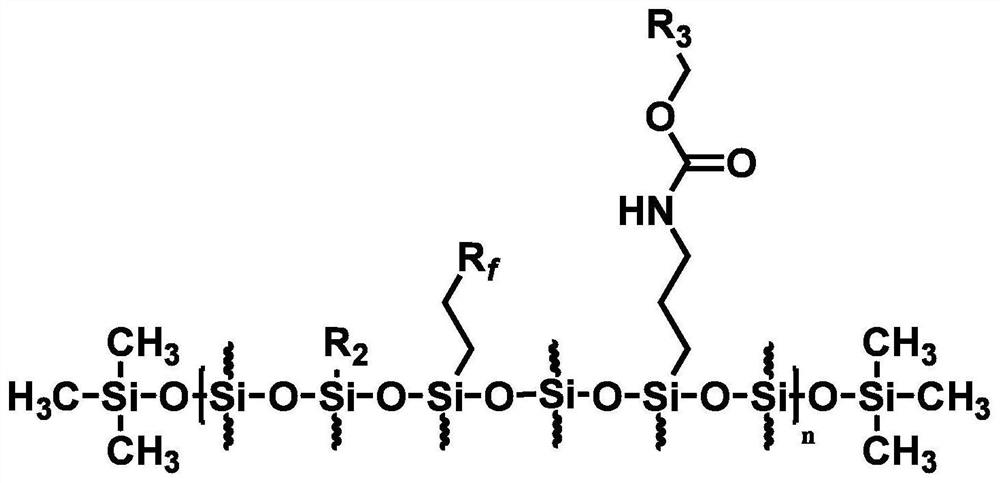

Polyurethane acrylate hybrid fluorine-containing silicon resin, preparation method and application

A polyurethane acrylate and acrylate technology, applied in the field of coating materials, can solve the problems of long surface drying time, low double bond conversion rate, coating surface defects, etc., and achieve high coating crosslinking density and hardness, fast light curing. Effects of speed, high double bond conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

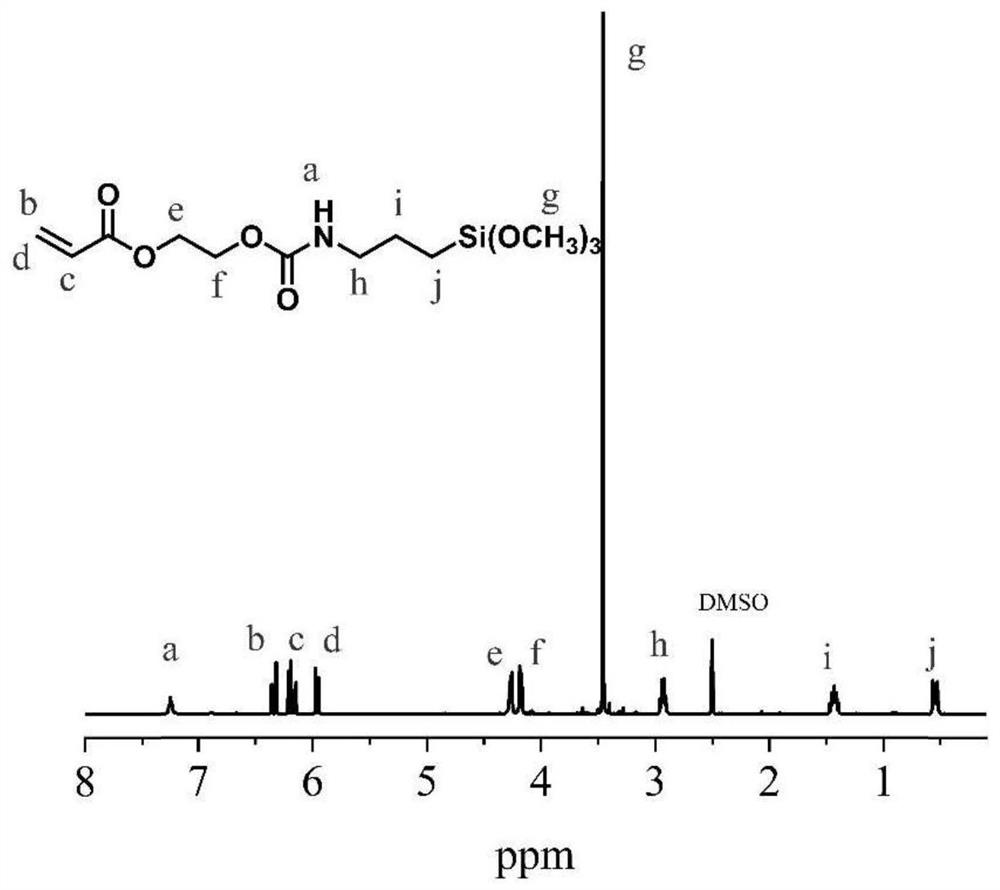

[0047] (1) Preparation of acryloxy-containing siloxane

[0048] Add 5.806g (0.05mol) of hydroxyethyl acrylate, 10.264g (0.05mol) of 3-isocyanatopropyltrimethoxysilane, dibutyltin dilaurate to a four-necked flask equipped with a stirrer, a reflux condenser and a thermometer. 0.016 g and 5 g of methyl ethyl ketone were stirred and reacted in an oil bath at 60° C. for 4 hours. After that, it was washed three times with n-hexane, and distilled under reduced pressure to obtain light yellow acryloyloxy-containing siloxane (A1).

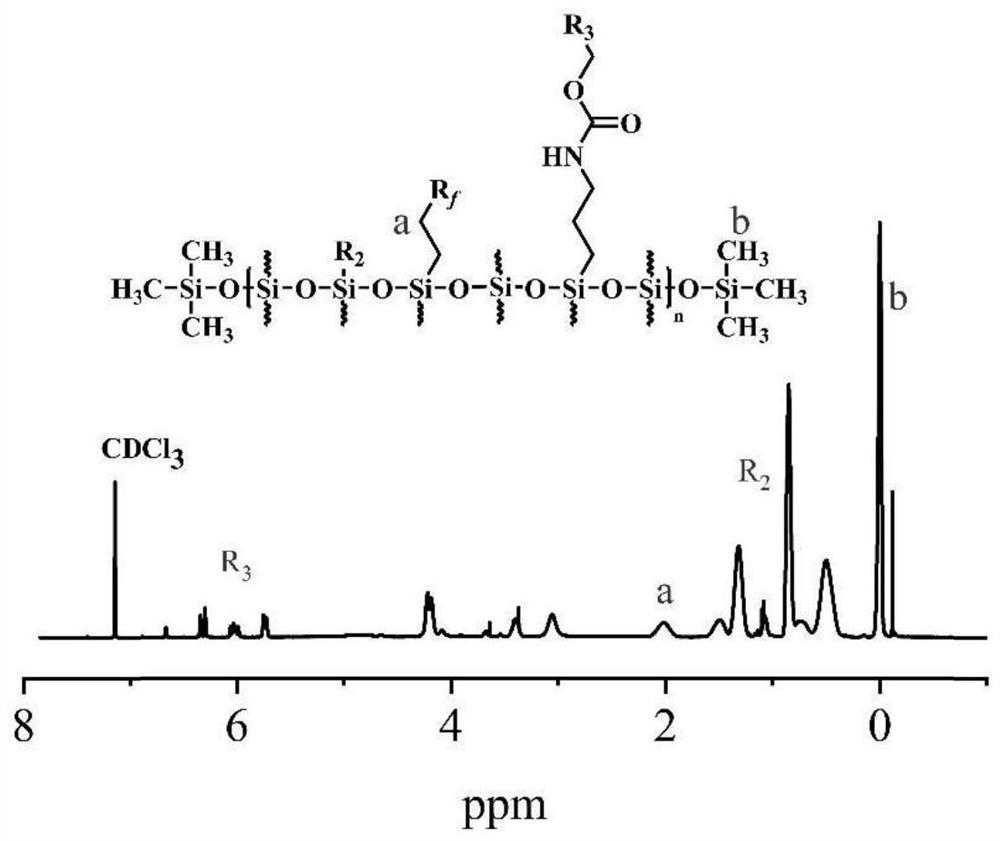

[0049] (2) Preparation of polyurethane acrylate hybrid fluorine-containing silicone resin

[0050] To a 100mL four-necked flask equipped with a reflux condenser, dropping funnel and thermometer, add 1H, 1H, 2H, 2H-perfluorooctyltrimethoxysilane 4.683g (0.01mol), propyltrimethoxysilane 6.571 g (0.04mol), 3.214g (0.01mol) of acryloxy-containing siloxane (A1), 5g of isopropanol and 0.02g of hydroquinone, the mixture was stirred uniformly and heated to 50°C. ...

Embodiment 2

[0054] (1) Preparation of acryloxy-containing siloxane

[0055] Add 10.000 g (0.05 mol) of 1,3-propanetriol diacrylate and 10.264 g (0.055 mol) of 3-isocyanatopropyl trimethoxysilane into a four-necked flask equipped with a stirrer, a reflux condenser and a thermometer , 0.022 g of stannous octoate and 6 g of methyl ethyl ketone were stirred and reacted in an oil bath at 65° C. for 4 hours. After that, it was washed three times with n-hexane, and distilled under reduced pressure to obtain light yellow acryloyloxy-containing siloxane (A2).

[0056] (2) Preparation of polyurethane acrylate hybrid fluorine-containing silicone resin

[0057] To a 100mL four-necked flask equipped with a reflux condenser, a dropping funnel and a thermometer, add 5.863g (0.01mol) of 1H, 1H, 2H, 2H-perfluorodecyltrimethoxysilane, 3.756g of ethyltrimethoxysilane g (0.025mol), 3.242g (0.008mol) of acryloxy-containing siloxane (A2), 5g of toluene and 2-tert-butyl Hydroquinone 0.025g, the mixture was ...

Embodiment 3

[0061] (1) Preparation of acryloxy-containing siloxane

[0062] Add 14.900 g (0.05 mol) of pentaerythritol triacrylate, 14.000 g (0.06 mol) of 3-isocyanatopropyltriethoxysilane, 14.000 g (0.06 mol) of dilauric acid di 0.029 g of butyltin and 8 g of toluene were stirred and reacted in an oil bath at 70° C. for 5 hours. After that, it was washed three times with n-hexane, and distilled under reduced pressure to obtain light yellow acryloyloxy-containing siloxane (A3).

[0063] (2) Preparation of polyurethane acrylate hybrid fluorine-containing silicone resin

[0064] To a 100mL four-necked flask equipped with a reflux condenser, a dropping funnel and a thermometer, add 4.104 g (0.01 mol) of 1H, 1H, 2H, 2H-nonafluorohexyltriethoxysilane, 4.928 propyltrimethoxysilane g (0.03 mol), 1.510 g (0.003 mol) of acryloxy-containing siloxane (A3), 6 g of toluene, and 0.04 g of hydroquinone, the mixture was stirred uniformly and heated to 40°C. A mixture of 0.064 g of a small amount of ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com