Pure beta ray corrying safe microball and its preparation

A β-ray and safe technology, applied in radiotherapy, radioactive carriers, radioactive physical shapes, etc., can solve problems such as patient health hazards, and achieve the effects of reliable safety, simple and easy-to-control preparation methods, and strong killing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

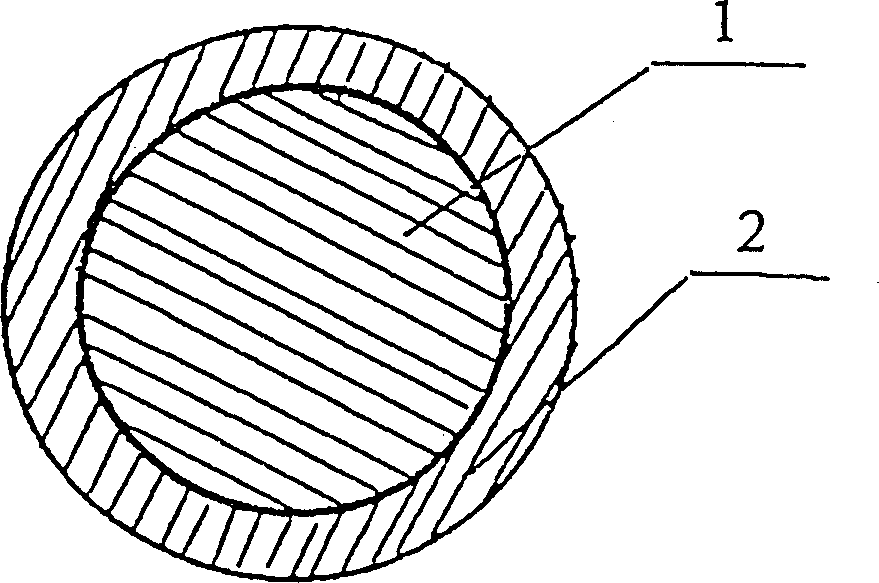

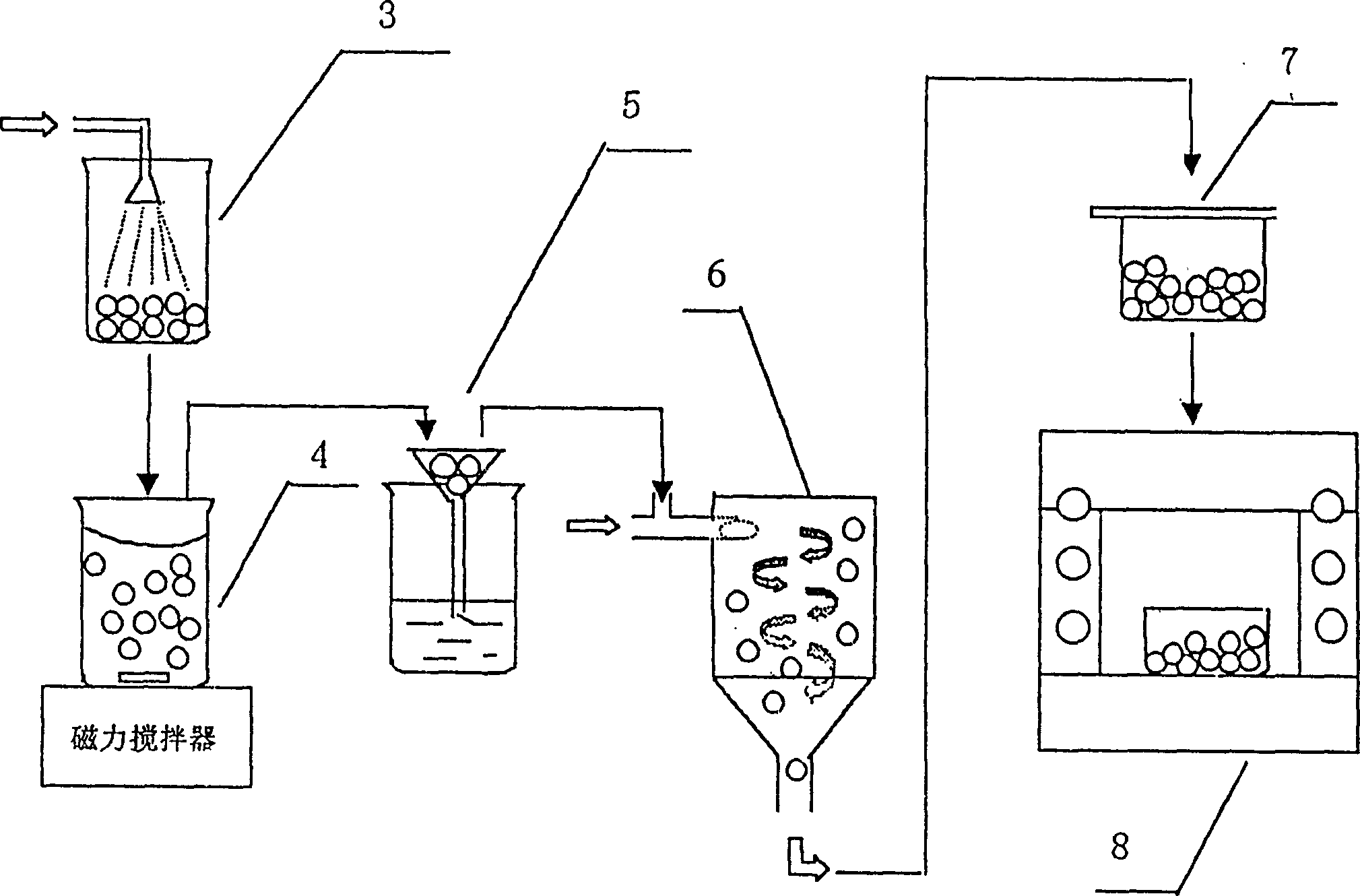

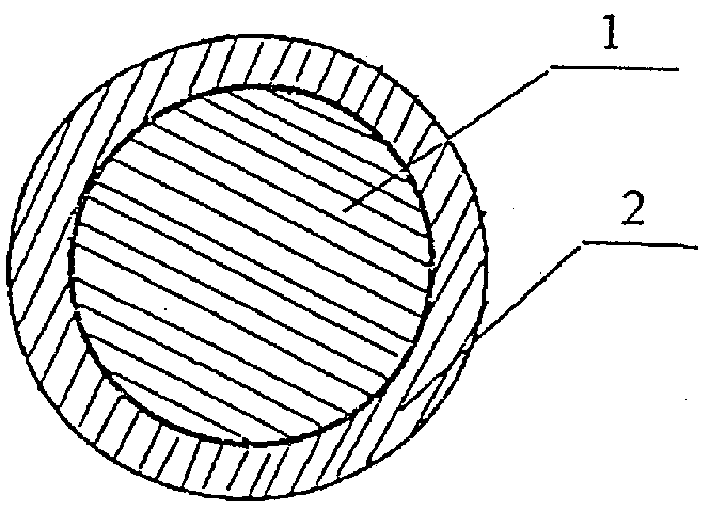

[0018] 100 grams will contain Y 2 O 3 , SiO 2 , Al 2 O 3 The Y-89 glass microspheres 1 are placed in a container, 0.4 g of silane coupling agent surfactant is added, and the pretreatment is completed by stirring 3, and then immersed in a sol containing 100% ethyl orthosilicate solution, and placed in a magnetic stirring On the stage, the gelatinization coating treatment 4 is carried out with stirring, and then the solid-liquid separation 5 is carried out. After organic solvent, ageing at room temperature for 25 days to stabilize the polymerization 7, and finally heating and evaporating heat treatment 8 at 500-600 ° C in a muffle furnace to make it vitrified, that is, the surface of the present invention has SiO 2 Coated yttrium-containing security microspheres. The diameter of the safety glass microspheres is in the range of 20 to 60 μm. Coated with SiO 2 The coated glass microspheres have a 30-day yttrium dissolution rate of 9 × 10 in a physiological simulant -7 g / g, ...

Embodiment 2

[0020] 100 grams will contain P 2 O 5 , Al 2 O 3 , MgO P-31 glass microspheres 1 in 0.5 g polyethylene glycol, stir to make it wet, and complete the pretreatment 3. Then, the above-mentioned glass microspheres 1 are immersed in a sol solution containing 80-90% of ethyl orthosilicate and 10-20% of aluminum nitrate, which can form a corrosion-resistant coating 2, and stirred to perform gelation coating treatment 4 , through the above-mentioned glass microsphere gel substance, carry out solid-liquid separation 5, take out the glass microspheres 1 coated with sol, and carry out cyclone together with the dry 40-60 ℃ hot air entering in the same direction at the inlet of the cyclone dryer Drying 6, removing part of the organic solvent and aging at room temperature for 30 days to stabilize the polymerization 7, and finally heating and evaporating heat treatment at 400-500°C in a muffle furnace 8, making it vitrified, and obtaining a surface with SiO 2 and Al 2 O 3 Coated phosph...

Embodiment 3

[0021] 100 grams will contain P 2 O 5 , Al 2 O 3 , MgO P-31 glass microspheres 1 in 0.5 g polyethylene glycol, stir to make it wet, and complete the pretreatment 3. Then, the above-mentioned glass microspheres 1 are immersed in a sol solution containing 80-95% of ethyl orthosilicate and 5-20% of butyl titanate which can form a corrosion-resistant coating 2 and stirred to perform gel coating. Treatment 4, the above-treated glass microsphere gel substance is subjected to solid-liquid separation 5, the sol-coated glass microspheres 1 are taken out, and the dry 40-60 ℃ hot air entering in the same direction at the inlet of the cyclone dryer Perform cyclone drying 6, remove part of the organic solvent and age at room temperature for 30 days to stabilize the polymerization 7, and finally heat it in a muffle furnace at 400-500 ℃ for heat treatment 8 to make it vitrified to obtain a surface with SiO 2 and TiO2 Coated phosphorus-containing safety microspheres. The diameter of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com