Recycling method of cadmium telluride waste

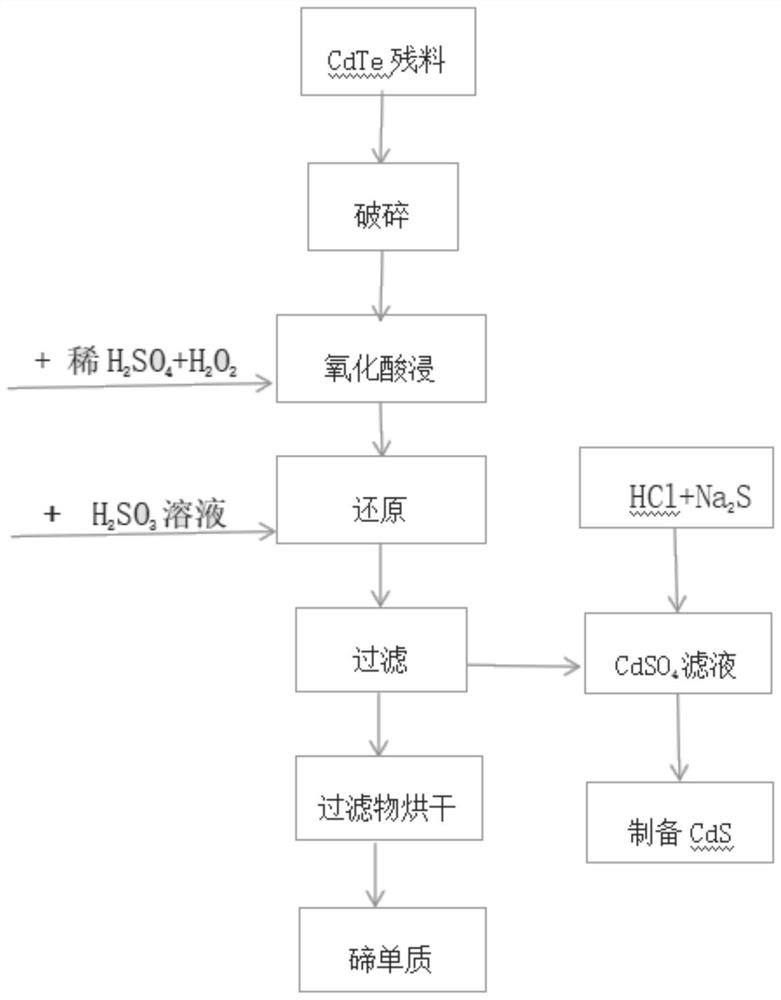

A recovery method, cadmium telluride technology, applied in the direction of cadmium sulfide, element selenium/tellurium, etc., can solve the problems of inability to directly recover cadmium sulfide compounds, etc., and achieve the effects of easy large-scale treatment, high economic benefits, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A. After crushing and screening 1 kg of collected cadmium telluride waste, obtain a powder with a particle size of 0.15-0.3 mm, and set aside;

[0055] B. mix the cadmium telluride powder obtained in step A with 70g / L H 2 SO 4 , 30%H 2 o 2 Mix according to the mass ratio of 1:6:1.3, react at 65°C, stir during the reaction, and after the black powder is completely dissolved, a mixed solution containing tellurous acid and cadmium salt is obtained;

[0056] C, the solution that step B obtains is added sulfurous acid solution; The weight ratio of sulfurous acid solution and cadmium telluride waste material is 2:1, the concentration of sulfurous acid solution is 6%, and the reaction time is 2h;

[0057] D, after reduction finishes, filter, obtain filter residue and filtrate;

[0058] ① The filter residue was repeatedly washed to neutral and then dried. After testing, the weight of the filter residue was 0.49kg, and the main component was tellurium. The recovery rate of t...

Embodiment 2

[0062] 5kg of cadmium telluride waste was tested by the method described in Example 1, only step B in Example 1 was changed, and other processes were unchanged. Step B is revised as: the cadmium telluride powder obtained in step A is mixed with 80g / L H 2 SO 4 , 30%H 2 o 2 Mix according to the mass ratio of 1:6:1.3, react at 65°C, stir during the reaction, and after the black powder is completely dissolved, a mixed solution containing tellurous acid and cadmium salt is obtained.

[0063] test results:

[0064] The filter residue was repeatedly washed to neutral and then dried. After testing, the weight of the filter residue was 2.446kg, and the main component was tellurium; the recovery rate of tellurium was 92.15%;

[0065] Dry the filter residue and put it into a vacuum distillation system for distillation and purification. The vacuum distillation temperature is set at 550°C and the vacuum degree is set at 5×10 -3 Pa, vacuum preservation after distillation, after testing...

Embodiment 3

[0068] 10kg of cadmium telluride waste was tested according to the method of Example 1, only step B in Example 1 was changed, and other processes were unchanged. In step B: mix the cadmium telluride powder obtained in step A with 80g / L H 2 SO 4 , 30%H 2 o 2 Mix according to the mass ratio of 1:6:1.3, react at 80°C, stir during the reaction, and after the black powder is completely dissolved, a mixed solution containing tellurous acid and cadmium salt is obtained;

[0069] test results:

[0070] The filter residue was repeatedly washed to neutral and then dried. After testing, the weight of the filter residue was 4.89kg, and the main component was tellurium; the recovery rate of tellurium was 92.09%;

[0071] Dry the filter residue and put it into a vacuum distillation system for distillation and purification. The vacuum distillation temperature is set at 550°C and the vacuum degree is set at 5×10 -3 Pa, vacuum preservation after distillation, after testing, the product we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com