Preparation method of ultralight high-temperature-resistant blocky mullite aerogel

An airgel and mullite technology, applied in the direction of aluminum silicate, silicate, etc., can solve the problems of difficult industrial production, low density and thermal conductivity, complex process, etc., to achieve industrial production, complete block Shaped structure and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

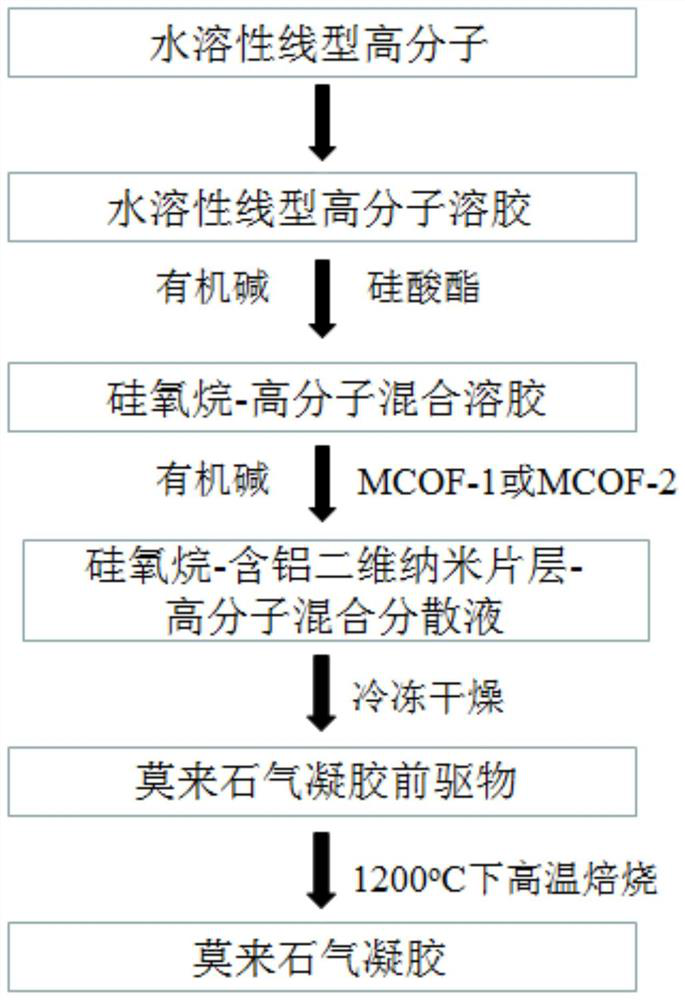

Method used

Image

Examples

Embodiment 1

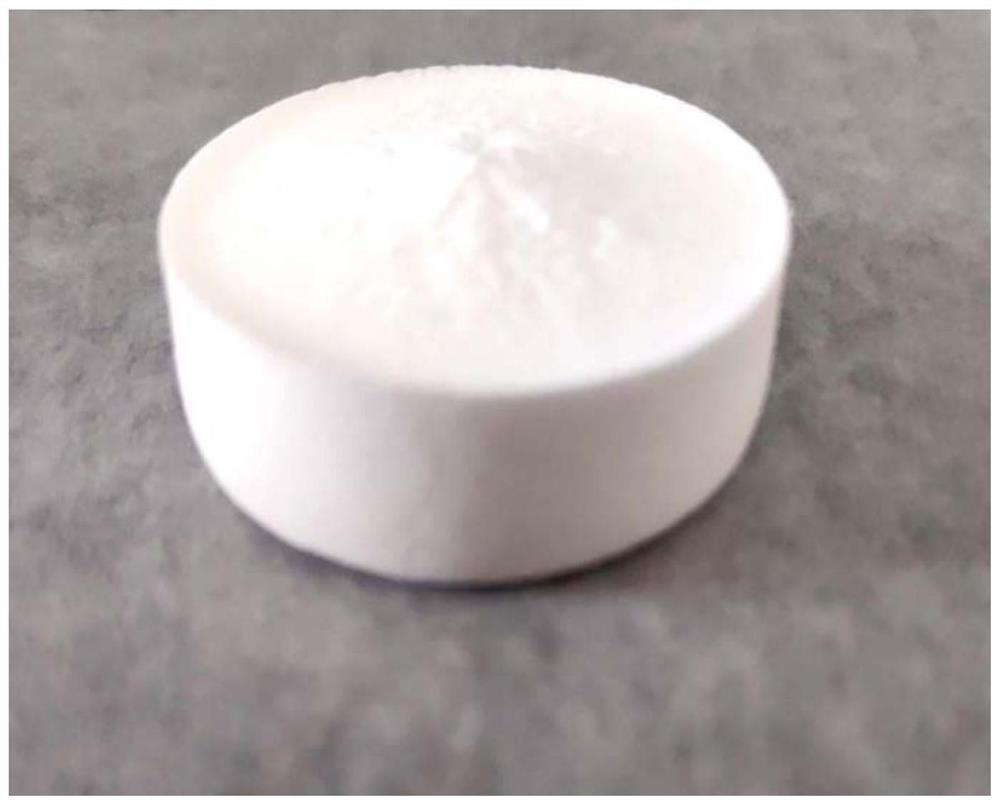

[0025] In a 100mL single-necked flask with magnetic stirring, add 50mL of deionized water and 0.5g of polyethylene oxide, after stirring at room temperature for 1h, add 0.26g of tetraethyl orthosilicate and 0.45g of tetramethylammonium hydroxide (25%wt aqueous solution) , after stirring again at room temperature for 1 h, add 0.5 g of MCOF-1 powder, adjust the pH of the solution to about 13 with tetramethylammonium hydroxide (25% wt aqueous solution), and stir again at room temperature for 0.5 h, pour the dispersion into the mold, and Freeze at -20°C for 24 hours; put the frozen ice directly into a freeze dryer for freeze-drying treatment, and after the sample is completely freeze-dried, roast it at 1200°C for 2 hours in an air atmosphere to obtain a density of 26 mg / cm 3 bulk mullite airgel.

Embodiment 2

[0027] In a 100mL single-necked flask with magnetic stirring, add 50mL deionized water and 0.5g polyvinyl alcohol, after stirring at room temperature for 1h, add 0.26g tetraethyl orthosilicate and 0.74g tetraethylammonium hydroxide (25%wt aqueous solution) , after stirring again at room temperature for 1 h, add 0.5 g of MCOF-1 powder, adjust the pH of the solution to about 13 with tetraethylammonium hydroxide (25% wt aqueous solution), and stir again at room temperature for 0.5 h, pour the dispersion into the mold, and Freeze at -20°C for 24 hours; put the frozen ice directly into a freeze dryer for freeze-drying treatment, and after the sample is completely freeze-dried, roast it at 1200°C for 2 hours in an air atmosphere to obtain a density of 32 mg / cm 3 bulk mullite airgel.

Embodiment 3

[0029] In a 100mL single-necked flask with magnetic stirring, add 50mL deionized water and 0.8g polyacrylamide, after stirring at room temperature for 1h, add 0.19g tetramethyl orthosilicate and 0.45g tetramethylammonium hydroxide (25%wt aqueous solution) , after stirring again at room temperature for 1 h, add 0.5 g of MCOF-1 powder, adjust the pH of the solution to about 13 with tetramethylammonium hydroxide (25% wt aqueous solution), and stir again at room temperature for 0.5 h, pour the dispersion into the mold, and Freeze at -20°C for 24 hours; put the frozen ice directly into a freeze dryer for freeze-drying treatment, and after the sample is completely freeze-dried, roast it at 1200°C for 2 hours in an air atmosphere to obtain a density of 29 mg / cm 3 bulk mullite airgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com