Acrylate film-forming resin containing adamantane structure, photoresist and preparation method

A technology of film-forming resin and acrylate, which is applied in the direction of photosensitive materials used in optomechanical equipment, etc., can solve the problems of poor adhesion between resin and substrate, poor dry etching resistance, high oxygen content, etc., and achieve excellent Anti-dry etching performance, excellent application effect, effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

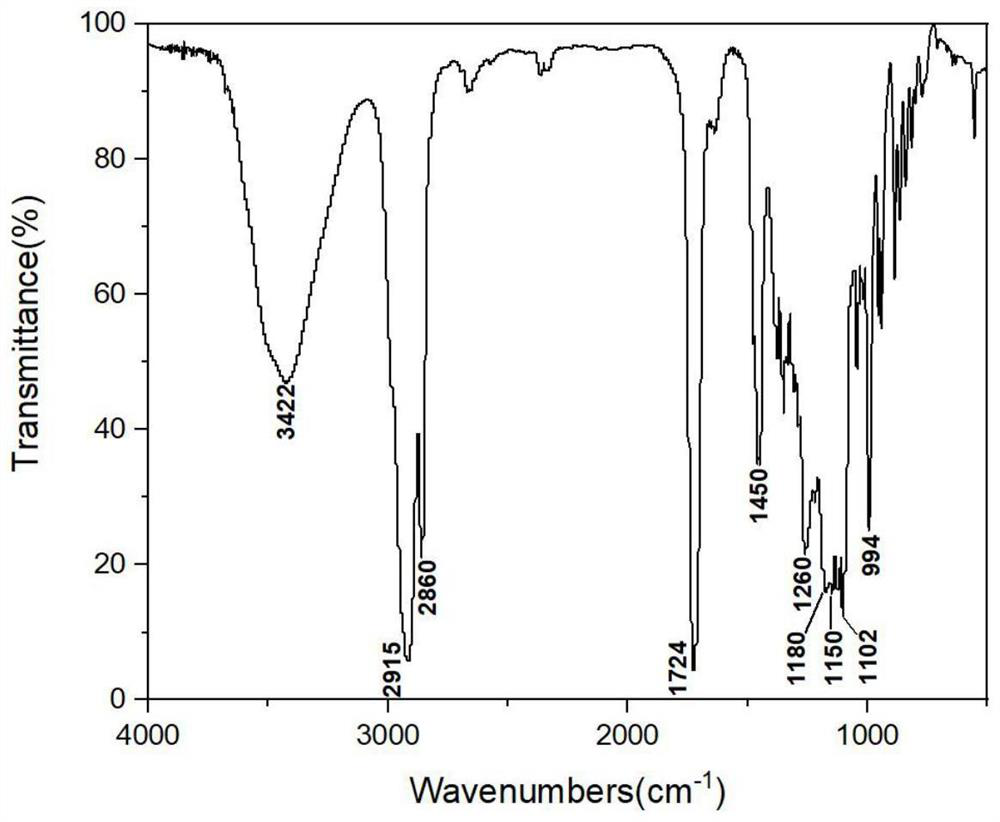

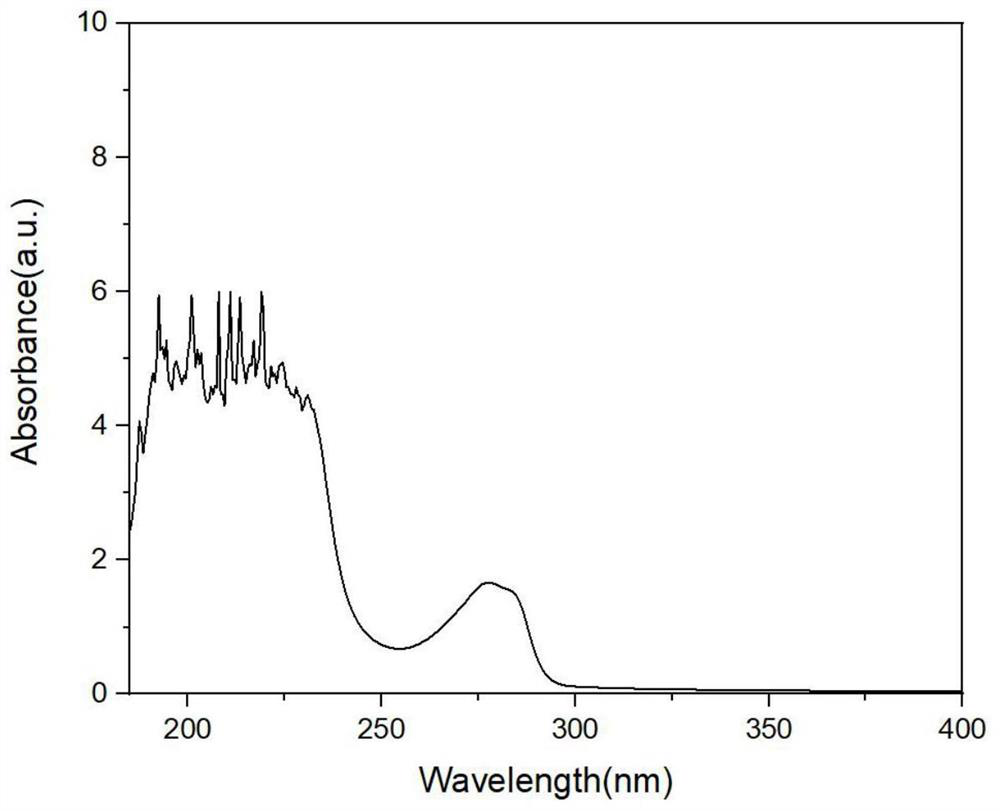

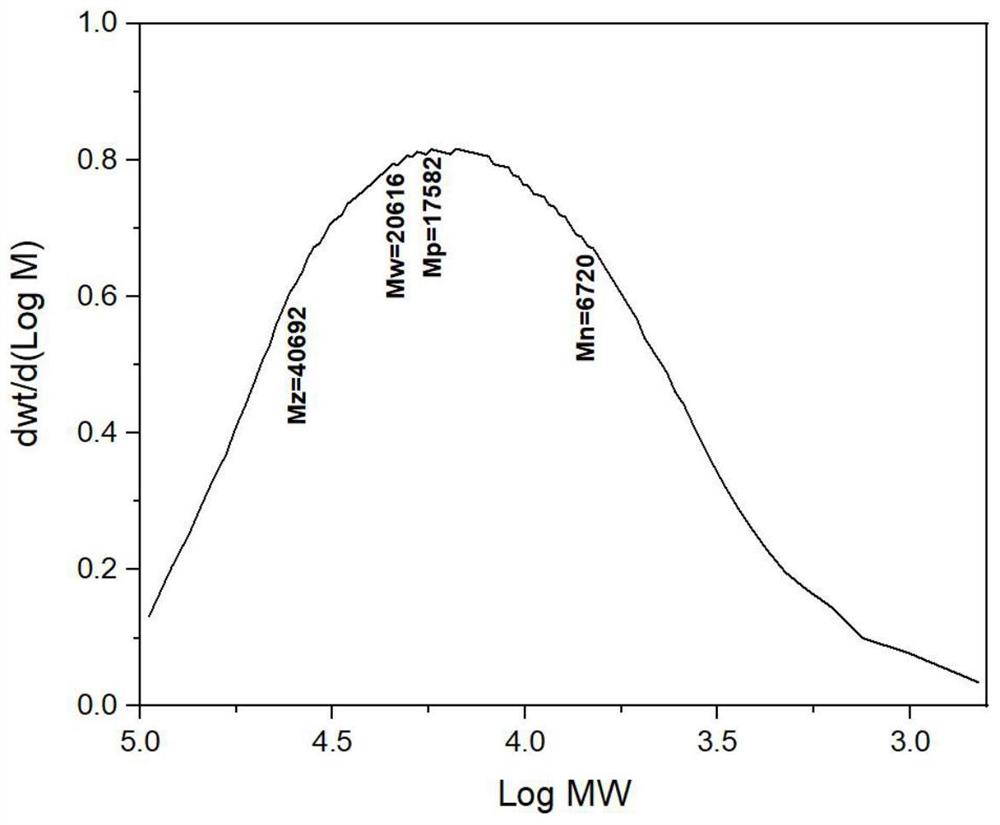

[0058] The adamantane-containing acrylate film-forming resin polymer is prepared through the following steps:

[0059] Nitrogen flushed the reaction device for 20 minutes, and 0.6 g of 2-(methylthio) ethyl methacrylate (I-1), 6.1 g of 2-ethyl-2-adamantyl methacrylate (II- 1), 2.7g of 3-hydroxyl-1-adamantyl acrylate (III-2) and 0.3g of azobisisobutyronitrile were put into a 250mL round bottom flask and the device was sealed. Inject 100mL of tetrahydrofuran into the airtight container with a syringe, heat the oil bath to 65°C, and reflux for 24h to end the reaction. After concentrating the obtained mixed solution, drop it into 500mL of methanol:water=1:1 mixed solution to produce a white precipitate. After filtration, a white solid was obtained. Dissolve the solid with tetrahydrofuran, repeat precipitation three times to purify the polymer, and filter. The obtained white solid polymer was first placed in a fume hood to dry naturally for 24 hours, and then dried in a vacuum oven ...

Embodiment 2

[0067] The adamantane-containing acrylate film-forming resin polymer is prepared through the following steps:

[0068] The reaction apparatus was flushed with nitrogen for 20 minutes. 0.6g of 2-(methylthio) ethyl methacrylate (I-1), 2.6g of 3-hydroxyl-1-adamantyl acrylate (III-2) and 0.3g of azobisisobutyl Nitrile was put into a 250mL round-bottomed flask and the device was sealed. After sealing, nitrogen was replaced three times, and 8.0g of 2-methyl-2-adamantyl acrylate (II-2) and 100mL of tetrahydrofuran were injected into the airtight container through a syringe. , heated in an oil bath to 65°C, and refluxed for 24 hours to end the reaction. After concentrating the obtained mixed solution, it was dropped into 500 mL of methanol:water=1:1 mixed solution to produce a white precipitate. Dissolve the solid, repeat the precipitation three times to purify the polymer, filter, and place the obtained white solid polymer in a fume hood to dry naturally for 24 hours, then dry it in...

Embodiment 3

[0072] The adamantane-containing acrylate film-forming resin polymer is prepared through the following steps:

[0073] The reaction apparatus was flushed with nitrogen for 20 minutes. 0.6g of 2-(methylthio) ethyl methacrylate (I-1), 4.9g of 1-adamantyl acrylate (II-3), 2.6g of 3-hydroxyl-1-adamantane Acrylate (III-1) and 0.3g of azobisisobutyronitrile were put into a 250mL round-bottomed flask and the device was sealed. After sealing, the nitrogen was replaced three times, and 100mL of tetrahydrofuran was injected into the airtight container through a syringe, and the oil bath was heated to 65°C, reflux for 24 hours to end the reaction, concentrate the obtained mixed solution, drop it into 500mL methanol: water = 1:1 mixed solution, a white precipitate is produced, obtain a white solid after filtration, dissolve the solid with tetrahydrofuran, and repeatedly precipitate Purify the polymer three times, filter, and place the obtained white solid polymer in a fume hood to air dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com