Preparation method of titanium dioxide/porous carbon supported composite photocatalyst

A technology of titanium dioxide and porous carbon, which is applied in the field of photocatalytic material preparation, can solve the problems of low stability and poor photodegradation ability, and achieve the effects of improved dispersion, effective degradation, and significant degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the titanium dioxide / porous carbon supported composite photocatalyst of the present invention is specifically:

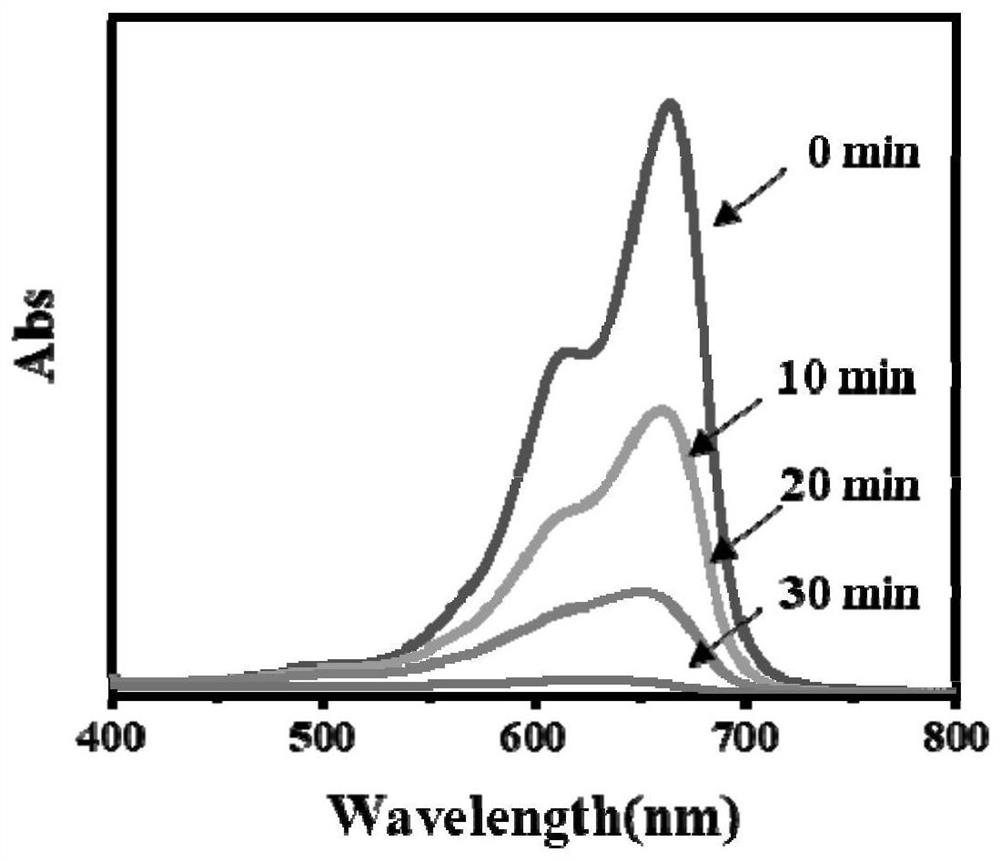

[0037] First weigh 10g of discarded coffee grounds and transfer it to a corundum boat, then put the corundum boat into the muffle furnace, set the temperature rise program, the temperature rise rate is 5°C / min, raise the temperature to 1000°C, keep it warm for 2 hours, and pass nitrogen, The nitrogen flow rate was 40 mL / min, and cooled to room temperature to obtain a porous carbon material. After that, 4 mL of tetrabutyl titanate was weighed, dissolved in 20 mL of absolute ethanol, and then 0.1 g of porous carbon material and 20 mL of glacial acetic acid were weighed, added to the above mixture and stirred at room temperature for 2 h. Then add the mixed solution into a hydrothermal autoclave lined with tetrachlorethylene, put the hydrothermal autoclave into an oven and heat it to 150°C for a heating time of 8 hours. Washing and dryi...

Embodiment 2

[0041] The preparation method of the titanium dioxide / porous carbon supported composite photocatalyst of the present invention is specifically:

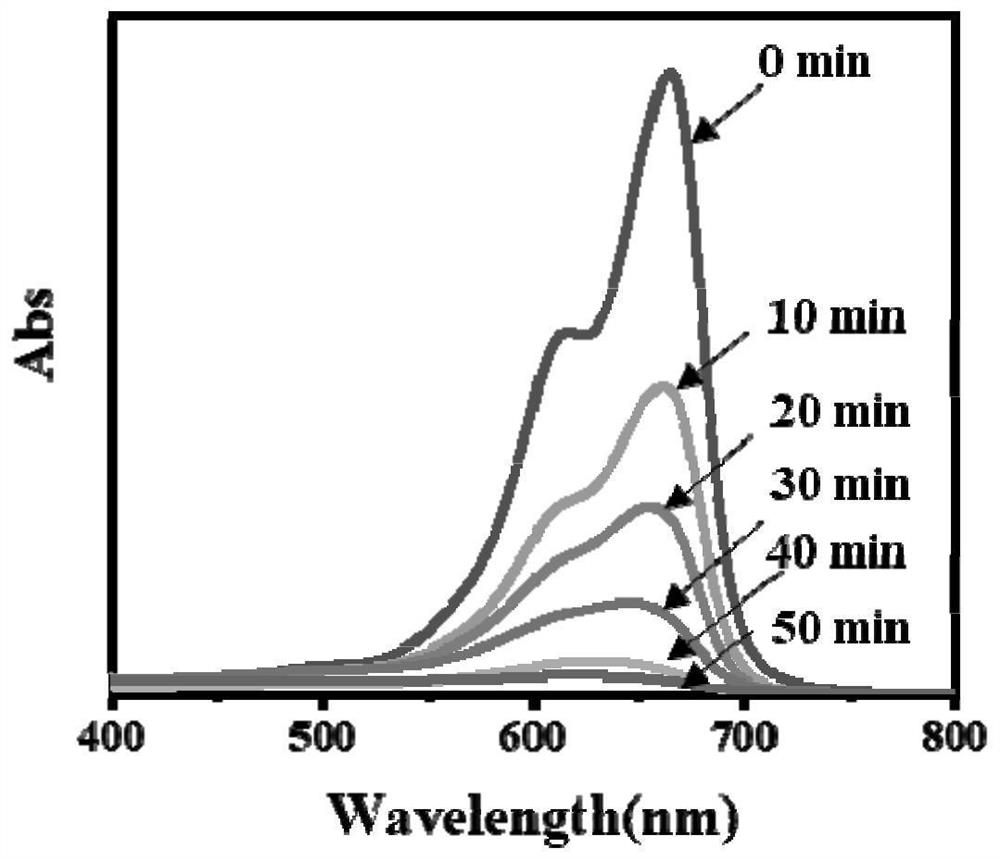

[0042] First weigh 10g of waste coffee grounds and transfer it to a corundum boat, then put the corundum boat into the muffle furnace, set the temperature rise program, the temperature rise rate is 5°C / min, raise the temperature to 900°C, keep it warm for 1.5h, and pass in nitrogen. The nitrogen flow rate was 40 mL / min, and cooled to room temperature to obtain a porous carbon material. After that, 5 mL of tetrabutyl titanate was weighed, dissolved in 25 mL of absolute ethanol, and then 0.5 g of porous carbon material and 20 mL of glacial acetic acid were weighed, added to the above mixture and stirred at room temperature for 2 h. Then add the mixed solution into a hydrothermal autoclave lined with tetrachlorethylene, put the hydrothermal autoclave into an oven and heat it to 180°C for a heating time of 8 hours. Washing and drying at...

Embodiment 3

[0045] The preparation method of the titanium dioxide / porous carbon supported composite photocatalyst of the present invention is specifically:

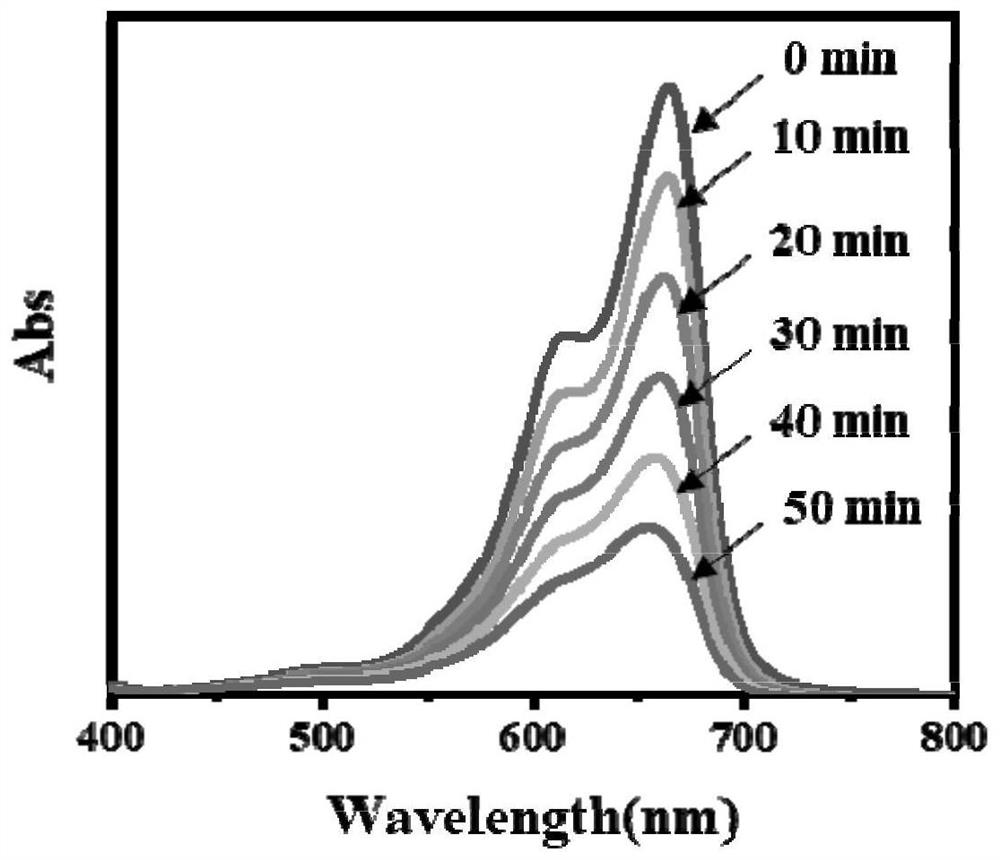

[0046] First weigh 10g of discarded coffee grounds, and transfer it to a corundum boat, then put the corundum boat into the muffle furnace, set the temperature rise program, the temperature rise rate is 5°C / min, raise the temperature to 700°C, keep it warm for 2 hours, and pass nitrogen, nitrogen The flow rate was 40 mL / min, and cooled to room temperature to obtain a porous carbon material. After that, 5 mL of tetrabutyl titanate was weighed, dissolved in 25 mL of absolute ethanol, and then 1 g of porous carbon material and 20 mL of glacial acetic acid were weighed, added to the above mixture and stirred at room temperature for 2 h. Then add the mixed solution into a hydrothermal autoclave lined with tetrachlorethylene, put the hydrothermal autoclave into an oven and heat it to 200°C for a heating time of 8 hours. Washing and drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com