Preparation method of polar polymer type coal water slurry additive and residual carbon separation method

A polymer type, coal-water slurry technology, applied in the field of coal chemical industry, can solve the problem of large use of flotation agents such as oil, and achieve the effect of increasing the charge capacity and improving the separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

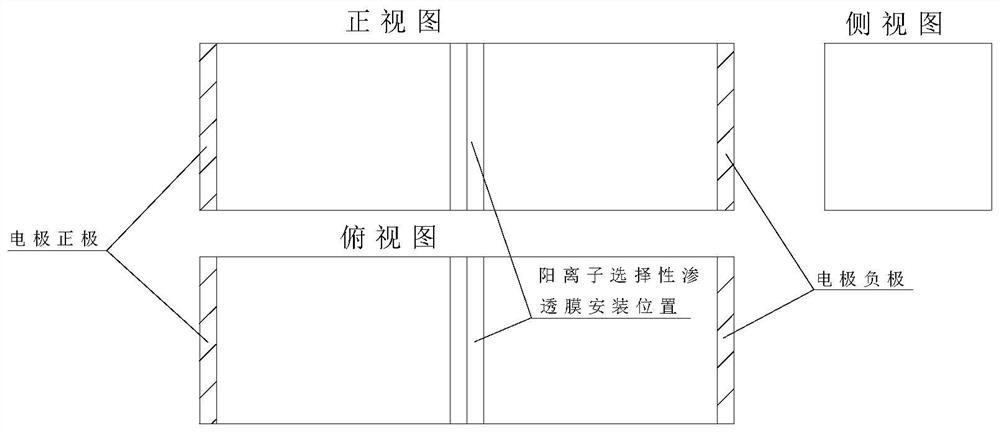

[0055] A ceramic cuboid reactor with an aspect ratio of 3 is placed horizontally, and a set of DC high voltage electrodes are placed inside the two square planes of the reactor. An aqueous solution of polyethylene glycol (number average molecular weight: 800) with a concentration of 10 wt% was placed in a cuboid reactor. An aqueous solution of adipic acid having a concentration of 10 wt % solubility was added to the aqueous polyethylene glycol solution. The mass ratio of polyethylene glycol to adipic acid is 20 / 80. The mixed solution was ultrasonically treated for 1 hour, and the power was selected at 1.5 kw; 1 wt% concentrated sulfuric acid relative to polyethylene glycol was added into the reactor every 30 minutes to obtain a mixed solution.

[0056]A layer of DuPont Nafion-NR211 cation selective permeation membrane was installed in the middle of the reactor, and the pH value of the mixed solution was adjusted to 7 by adding ammonia water. Turn on the high-voltage electrod...

Embodiment 2

[0060] A ceramic cuboid reactor with an aspect ratio of 5 is placed horizontally, and a set of DC high-voltage electrodes are placed inside the two square planes of the reactor. An aqueous solution of polyethylene glycol (with a number average molecular weight of 4000) at a concentration of 12 wt % was placed in a cuboid reactor. An aqueous solution of adipic acid having a concentration of 15% by weight of solubility was added to the aqueous polyethylene glycol solution. The mass ratio of polyethylene glycol to adipic acid is 30 / 70. The mixed solution was ultrasonically treated for 2 hours, and the power was selected as 2kw; every 40 minutes, 3 wt% concentrated sulfuric acid relative to polyethylene glycol was added into the reactor to obtain a mixed solution.

[0061] Two layers of DuPont Nafion-NR211 cation-selective permeable membranes were installed in the middle of the reactor, and the pH value of the mixed solution was adjusted to 7 by adding sodium hydroxide. Turn on ...

Embodiment 3

[0065] A ceramic cuboid reactor with an aspect ratio of 6 is placed horizontally, and a set of DC high voltage electrodes are placed inside the two square planes of the reactor. An aqueous solution of polyethylene glycol (with a number average molecular weight of 5000) at a concentration of 15 wt % was placed in a rectangular parallelepiped reactor. An aqueous solution of adipic acid having a concentration of 20 wt % solubility was added to the aqueous polyethylene glycol solution. The mass ratio of polyethylene glycol to adipic acid is 40 / 60. The mixed solution was ultrasonically treated for 3 hours, and the power was selected as 3kw; every 50 minutes, 5 wt% concentrated sulfuric acid relative to polyethylene glycol was added into the reactor to obtain a mixed solution.

[0066] Three layers of DuPont Nafion-NR211 cation selective permeation membranes were installed in the middle of the reactor, and the pH value of the mixed solution was adjusted to 7.5 by adding ammonia wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com