Preparation method of coal-based graphene in molten salt system

A graphene and system technology, applied in the field of coal-based graphene preparation, can solve the problems of particle pollution, environmental hazards, etc., and achieve the effects of high purity, controllable layer number, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, ball-milled anthracite is used as the processing object.

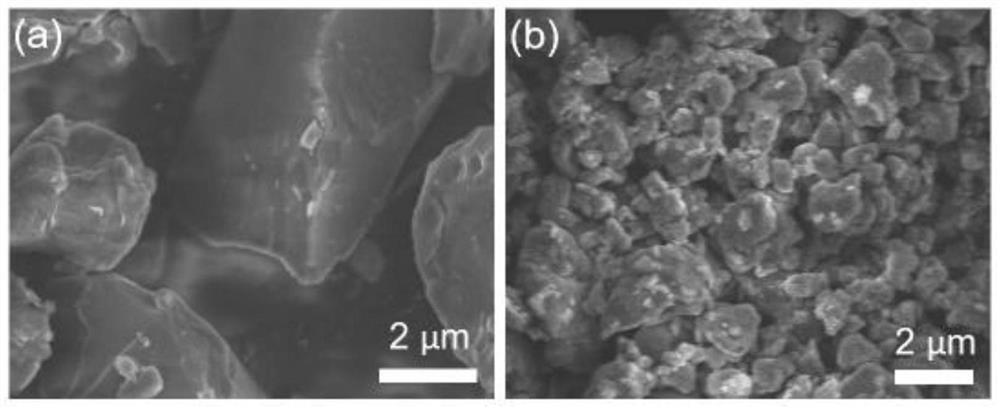

[0031] Weigh 2 g of anthracite, add 5 g of potassium chloride at the same time, and mix the two evenly. Using ethanol as a solvent, wet ball milling was adopted, and the ball milling speed and time were set at 600 rpm and 6 h, respectively. The obtained product was washed with deionized water and ethanol three times respectively, and then dried at 80° C. for 12 h for use. Scanning electron microscope images of samples before and after ball milling are shown in figure 1 , it can be seen that the coal particle size after ball milling is uniform, and the particle size is greatly reduced, reaching about 1 micron.

Embodiment 2

[0033] In this embodiment, amorphous graphene prepared in molten salt is used as the processing object.

[0034] (1) Use a ball mill (or mortar) to grind 200 mg of ball-milled anthracite (with a particle size of 1 to 10 μm) and 2 g of K 2 CO 3 Grind well until well blended.

[0035] (2) Transfer the mixture of the two to a corundum porcelain boat and put it into a tube furnace for heat treatment. Argon was introduced into the tube furnace, the temperature was raised to 900°C at a rate of 5°C / min, and kept for 5h. After the reaction is finished, cool to room temperature, collect samples, and use 1mol L -1 Sulfuric acid was treated at 80°C for 8h, then washed with water for 5 times and then dried (80°C, 12h) to obtain the amorphous graphene product.

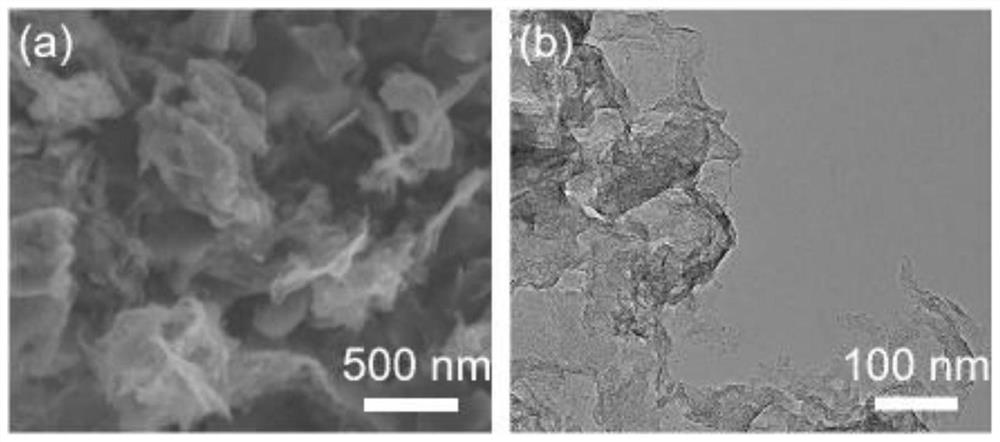

[0036] The scanning electron microscope and transmission electron microscope photos of amorphous graphene prepared under this condition are as follows: figure 2 As shown, it can be seen that the molten salt system can success...

Embodiment 3

[0038] In this embodiment, graphene prepared in molten salt is used as the processing object.

[0039] (1) Use a ball mill (or mortar) to grind 200 mg of ball-milled anthracite (particle size 10-100 μm), 2 g of KCl / CaCl 2 and 400mg FeCl 3 Grind well until well blended.

[0040] (2) The above mixture was transferred to a corundum porcelain boat, and heat-treated in a tube furnace. Argon gas was introduced into the tube furnace, the temperature was raised to 800°C at a rate of 10°C / min, and kept for 5h. After the reaction is finished, cool to room temperature, collect the sample, first remove the salt by washing with water, and then in 1mol L -1 Sulfuric acid was treated at 80°C for 8 hours, washed with water for 5 times and then dried to obtain a high-purity product.

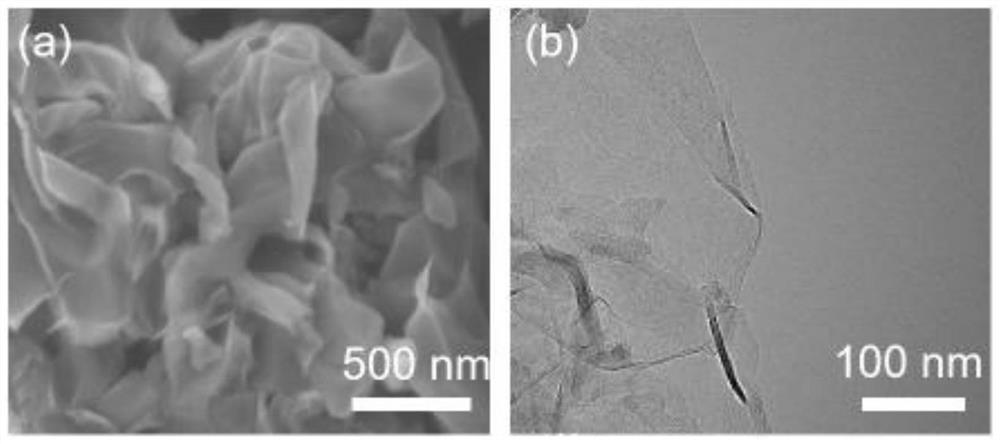

[0041] Scanning electron microscopy and transmission electron microscopy of graphene prepared under this condition are as follows: image 3 As shown, it can be seen that the surface of the graphene sheet is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com