A method for the recovery of rare earth and energy substances from rare earth hyperaccumulator plants

A technology for hyper-enrichment of plants and rare earths, applied in the field of recycling rare earths and energy substances, can solve the problems of untreated pyrolysis gas, waste of resources, human harm, etc., and achieve high-value resource utilization, high recovery efficiency, Avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

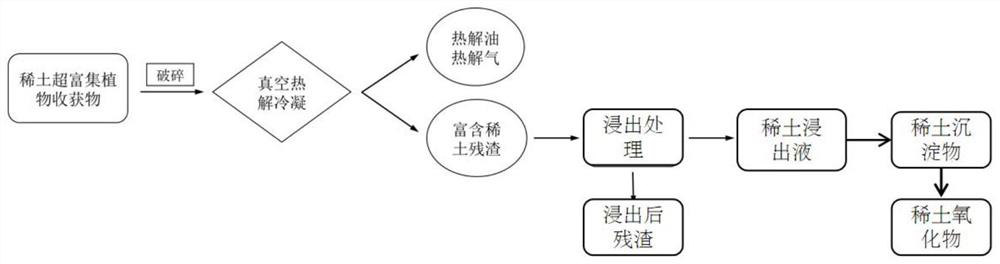

[0049] Example 1 A method of recovering energy substances from the rare earth hyperaccumulator Osmanthus edodes by using a vacuum pyrolysis segmental condensation device

[0050] 1. Vacuum pyrolysis segmental condensation device

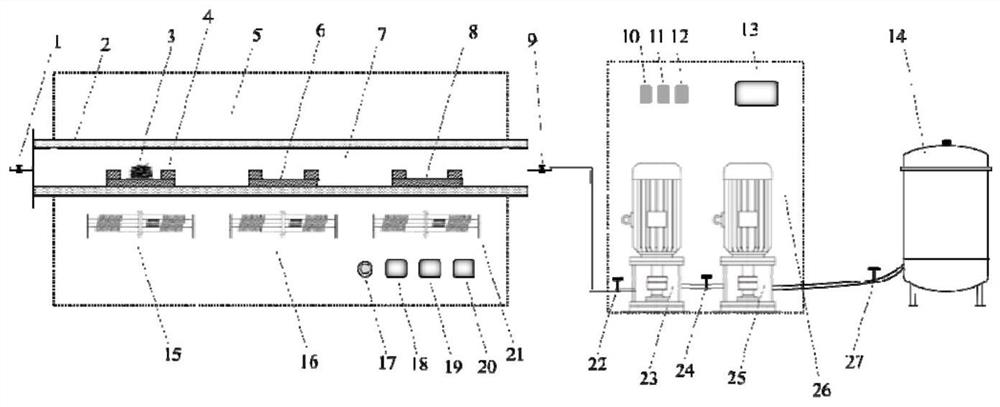

[0051] The structure of the vacuum pyrolysis segmental condensation device is as follows: figure 1 As shown, it includes three parts: vacuum pyrolysis condensation system 5 , vacuum pumping system 26 and pyrolysis gas collection system 14 . Vacuum pyrolysis condensation system 5 is divided into inlet valve 1 and outlet valve 9, and a corundum tube 7 is placed in the vacuum pyrolysis condensation assembly 2. The first temperature zone in the tube is the pyrolysis zone, and a corundum crucible-4 is placed to hold Put the super-enrichment plant harvest 3, and control the temperature of the first temperature zone by controlling the silicon molybdenum rod thermocouple heating element 15 through the temperature regulator 18; the second temperature zone is...

Embodiment 2

[0058] Example 2 A method for recovering rare earth and energy substances from the rare earth hyperaccumulator Osmanthus fragrans

[0059] (1) Drying the rare earth super-enriched Osmanthus edulis plants, and placing the dried plants in a shear crusher for crushing to obtain uniform Osmanthus osmanthus powder;

[0060] (2) Weighing 40 g of the Osmanthus fragrans powder above was subjected to pyrolysis and condensation treatment in a vacuum pyrolysis segmental condensation device. Set the vacuum degree of the first pyrolysis zone to 10Pa, the final pyrolysis temperature to 700°C, the heating rate to 30°C / min, and the retention time to 30min. Set the condensation temperature of the second condensation zone to 180°C, and the condensation temperature of the third condensation zone to 80°C;

[0061] (3) After the pyrolysis is complete, the pyrolysis oil and pyrolysis gas are collected to obtain a total of 27.666g of pyrolysis oil and pyrolysis gas. Using GC-MS to analyze the pyrol...

Embodiment 3

[0066] Example 3 A method for recovering rare earth and energy substances from rare earth hyperaccumulator pokeweed

[0067] (1) Drying the rare earth super-enriched Pokeweed plants, and placing the dried plants in a shear crusher for crushing to obtain uniform Pokeweed powder;

[0068] (2) Weighing 40 g of the pokeweed powder above was subjected to pyrolysis and condensation treatment in a vacuum pyrolysis staged condensation device. Set the vacuum degree of the first pyrolysis zone to 50Pa, the final pyrolysis temperature to 650°C, the heating rate to 25°C / min, and the retention time to 30min. Set the condensation temperature of the second condensation area to 160°C, and the third condensation area to 70°C;

[0069] (3) After the pyrolysis is complete, the pyrolysis oil and pyrolysis gas are collected to obtain a total of 35.47 g of pyrolysis oil and pyrolysis gas. Using GC-MS to analyze the pyrolysis oil and pyrolysis gas, it is found that the pyrolysis oil and gas are mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com