Preparation method of dichloropropanol

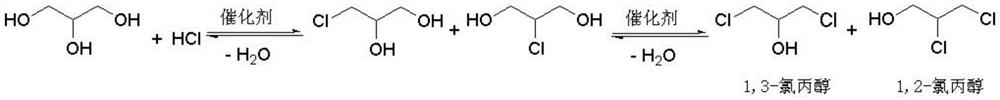

A dichloropropanol, a catalytic preparation technology, applied in the field of fine chemistry, can solve problems such as the inability to directly use salty crude glycerin, high catalyst dosage, and influence on reaction yield, and achieve excellent thermal stability, catalytic activity, and catalytic activity High, to avoid the effect of polycondensation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

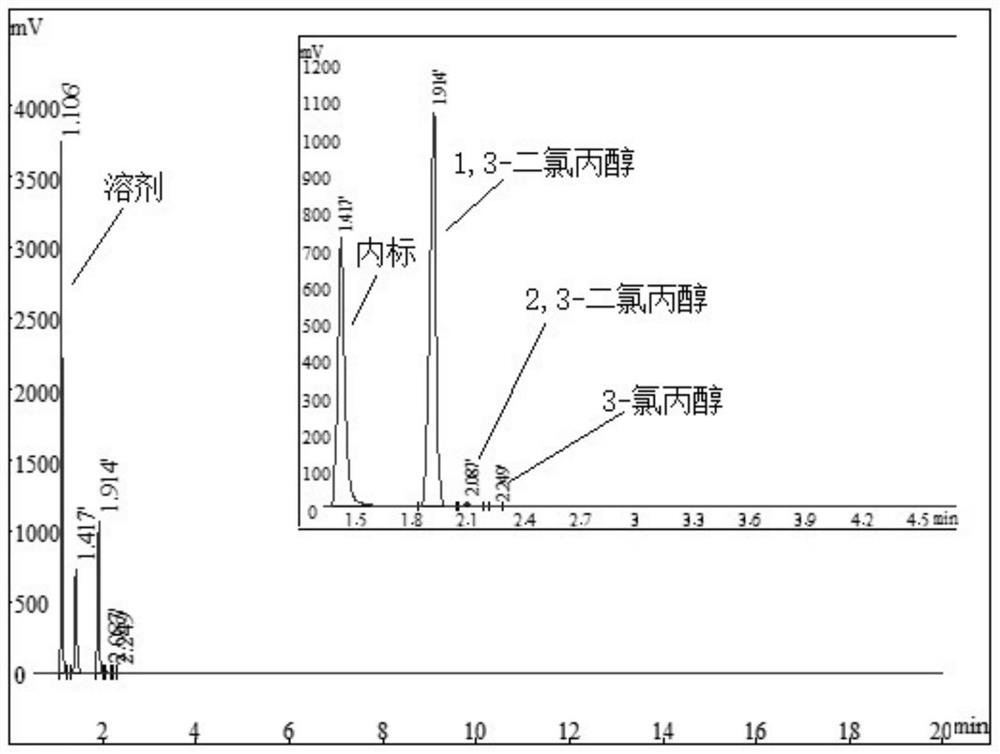

[0035] The preparation of dichloropropanol is as follows:

[0036] (1) Catalyst preparation

[0037] Weigh 146.16g (1mol) of adipic acid, 39.92g (0.25mol) of iron oxide and 40.69g (0.5mol) of zinc oxide into the reactor, add 350g of water and heat to reflux for 3h, remove most of the water under reduced pressure and filter to obtain brown solid. The solid was vacuum-dried and ground to obtain a total of 196.5 g of composite catalysts.

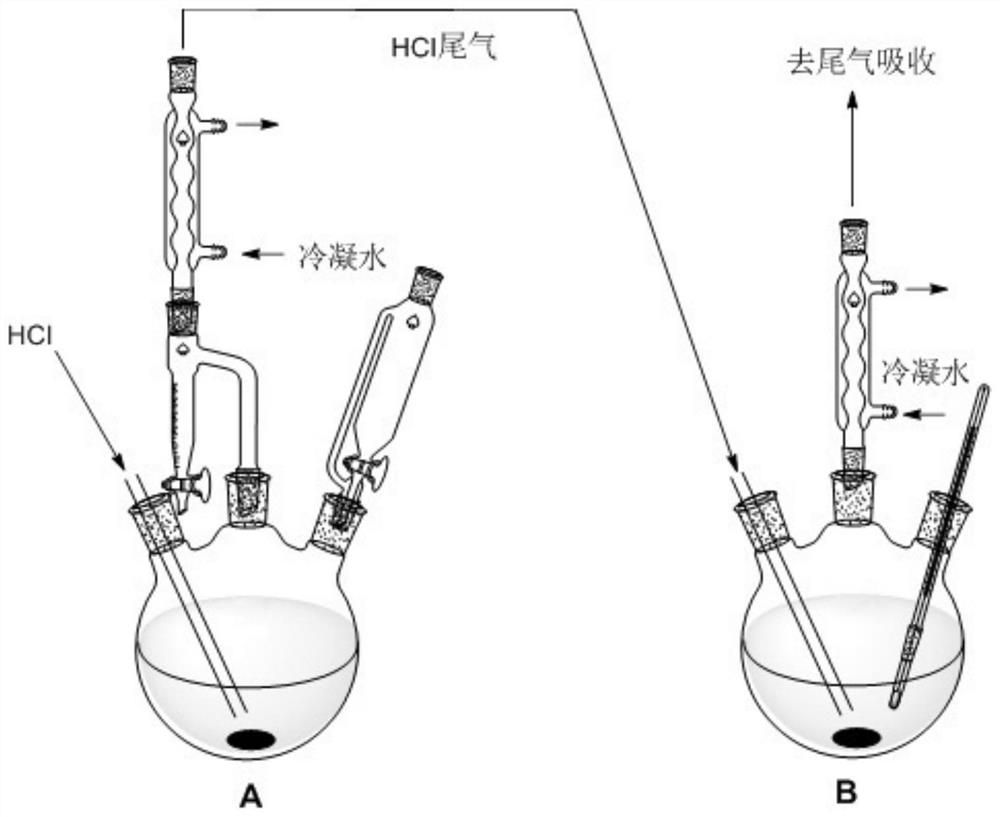

[0038] (2) Take by weighing 9.21g (5%) of composite catalyst and 193.9g (2mol) of glycerol with a purity of 95%, add in reactor A equipped with stirring, temperature measuring, water separation device and reflux device, and take by weighing composite catalyst 9.21g and purity are 95% glycerin 193.9g (2mol), add in the reactor B that stirring, temperature measurement, reflux device and tail gas absorption device are equipped with;

[0039](3) Turn on the stirring, raise the temperature of both reactors A and B to 120°C, then feed hydrogen chl...

Embodiment 2

[0043] The preparation of dichloropropanol is as follows:

[0044] (1) Catalyst preparation

[0045] Weigh 146.17g (1mol) of adipic acid, 39.96g (0.25mol) of iron oxide, 20.37g (0.25mol) of zinc oxide and 12.80g (0.125mol) of aluminum oxide and place them in a reactor, add 350g of water and heat to reflux for 3h, After most of the water was removed under reduced pressure, a brown solid was obtained by filtration. The solid was vacuum-dried and ground to obtain a total of 191.9 g of composite catalysts.

[0046] (2) Take by weighing 5.53g (3%) of the composite catalyst and 193.9g (2mol) of glycerol with a purity of 95%, add in the reactor A equipped with stirring, temperature measuring, water separation device and reflux device, and take the composite catalyst in addition 5.53g and purity are 95% glycerin 193.9g (2mol), add in the reactor B that stirring, temperature measurement, reflux device and tail gas absorption device are equipped with;

[0047] (3) Turn on the stirrin...

Embodiment 3

[0051] The preparation of dichloropropanol is as follows:

[0052] (1) Catalyst preparation

[0053] Weigh 146.16g (1mol) of adipic acid, 39.96g (0.25mol) of iron oxide, 8.14g (0.10mol) of zinc oxide and 20.39g (0.20mol) of aluminum oxide and place them in a reactor, add 350g of water and heat to reflux for 3h, After most of the water was removed under reduced pressure, a brown solid was obtained by filtration. The solid was vacuum-dried and ground to obtain a total of 183.3 g of composite catalysts.

[0054] (2) Take by weighing 18.42g (10%) of composite catalyst and 204.6g (2mol) of glycerol with a purity of 90%, add in reactor A equipped with stirring, temperature measuring, water separation device and reflux device, and take composite catalyst 18.42g and purity are 204.6g (2mol) of glycerol of 90%, add in the reactor B that stirring, temperature measurement, reflux device and tail gas absorption device are equipped with;

[0055] (3) Turn on the stirring, raise the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com