Biodegradable copolyester hot melt adhesive and preparation method thereof

A biodegradable, hot-melt adhesive technology, used in adhesives and other directions, can solve the problems of uneven melt blending and granulation performance, slow degradation of hot melt adhesives, and low melt spinning efficiency, and achieve excellent spinnability, good Tensile strength and bonding effect, the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

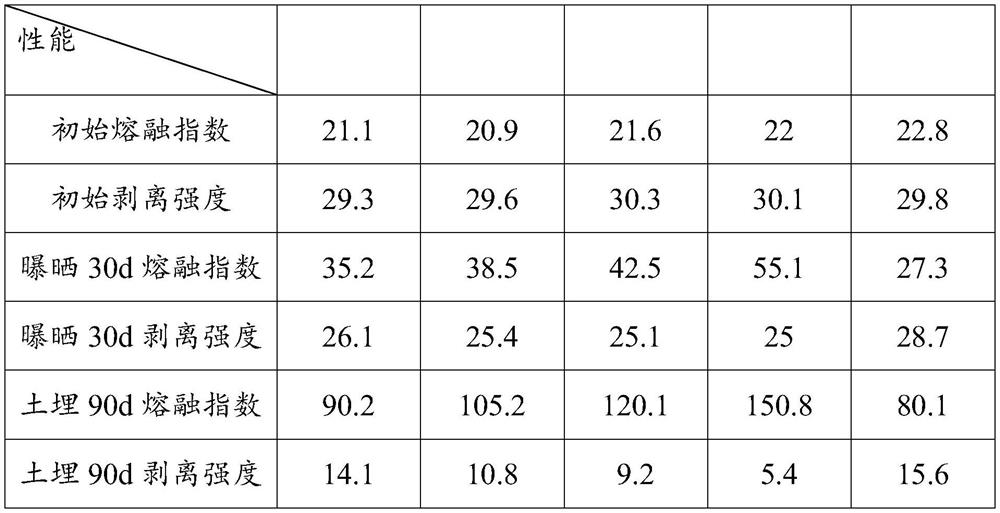

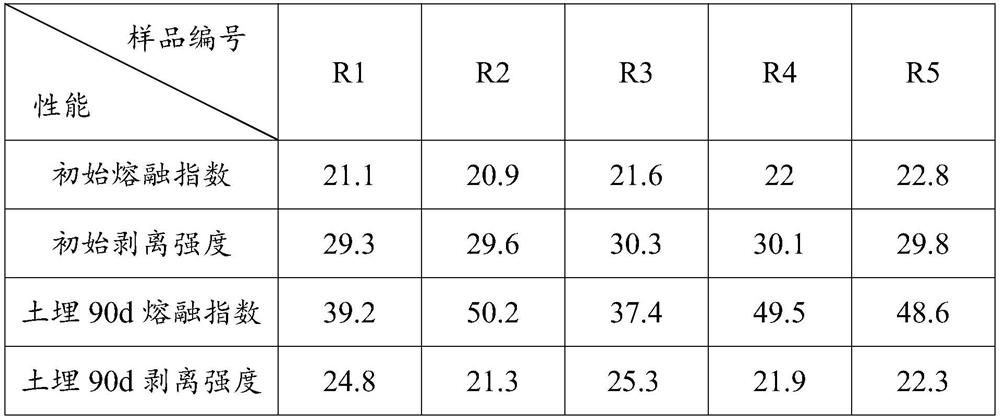

Embodiment 1

[0028] Biodegradable copolyester hot-melt adhesive, its preparation method comprises the following steps:

[0029] (1) 142g 1,6 adipic acid, 104.3g 1,4-butanediol, 39.2g polydimethylsiloxane (the number average molecular weight is 400), 40.3g polyethylene glycol (the number average molecular weight is 400) and 0.08g of tetrabutyl titanate were put into the No. 1 esterification reaction kettle, and the reaction temperature was adjusted to 150-190°C; when the distilled water in the esterification kettle was 95% or more of the theoretical water output, the esterification reaction was completed and obtained Esterification solution A;

[0030] 242g terephthalic acid, 169.2g 1,4 butanediol, 60g polydimethylsiloxane (number average molecular weight 400), 65.4g polyethylene glycol (number average molecular weight 400) and 0.13g titanic acid Tetrabutyl ester is put into No. 2 esterification reaction kettle, and the reaction temperature is adjusted to 190-230°C; when the distilled wate...

Embodiment 2

[0034] Biodegradable copolyester hot-melt adhesive, its preparation method comprises the following steps:

[0035] (1) 177.4g 1,6 adipic acid, 130.8g 1,4-butanediol, 23.6g polydimethylsiloxane (number average molecular weight is 400), 50.6g polyethylene glycol (number average molecular weight 400) and 0.09g of tetrabutyl titanate were put into the No. 1 esterification reaction kettle, and the reaction temperature was adjusted to 150-190°C; when the distilled water in the esterification kettle was 95% or more of the theoretical water output, the esterification reaction ended Obtain esterification solution A;

[0036] 201.7g terephthalic acid, 140.8g 1,4-butanediol, 24.2g polydimethylsiloxane (the number average molecular weight is 400), 54.4g polyethylene glycol (the number average molecular weight is 400) and 0.1 g tetrabutyl titanate is put into the No. 2 esterification reaction kettle, and the reaction temperature is adjusted to 190-230°C; when the distilled water in the es...

Embodiment 3

[0040] Biodegradable copolyester hot-melt adhesive, its preparation method comprises the following steps:

[0041] (1) 142g 1,6 adipic acid, 96.5g 1,4-butanediol, 39.2g polydimethylsiloxane (the number average molecular weight is 400), 75.7g polyethylene glycol (the number average molecular weight is 400) and 0.1g of dibutyltin dilaurate are put into No. 1 esterification reaction kettle, and the reaction temperature is adjusted to 150-190°C; when the distilled water in the esterification kettle is 95% or more of the theoretical water output, the esterification reaction is completed to obtain Esterification solution A;

[0042] 242g terephthalic acid, 167.5g 1,4-butanediol, 60g polydimethylsiloxane (number average molecular weight is 400), 131.4g polyethylene glycol (number average molecular weight is 400) and 0.15g dimethicone Put dibutyltin laurate into the No. 2 esterification reaction kettle, adjust the reaction temperature to 190-230°C; when the distilled water in the est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com