Straw fermented feed and production method thereof

A technology of fermented feed and production method, applied in the direction of animal feed, animal feed, animal feed molding or processing, etc., can solve the problems of difficult product quality control, high mycotoxin content, low probiotic bacteria count, etc. The effect of reducing energy consumption, fine and uniform feed particles, and low mycotoxin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

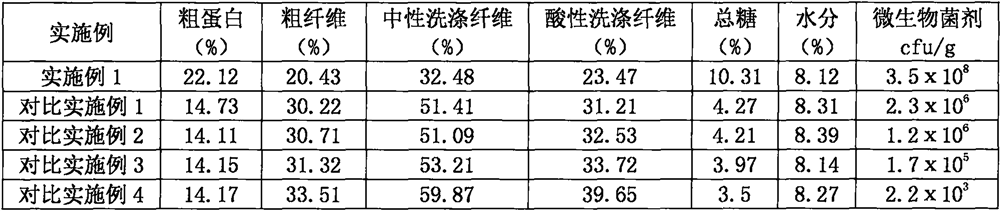

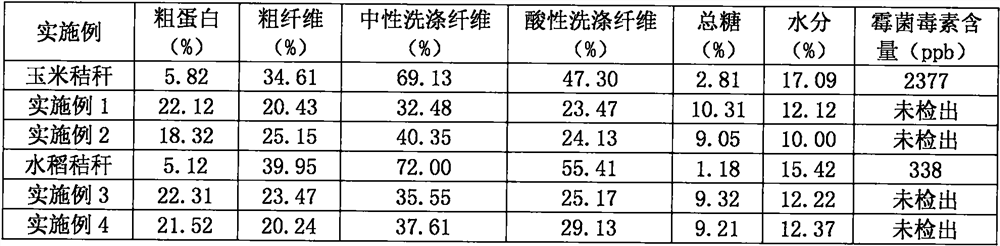

[0046] A straw fermented feed, wherein, the crude protein content is 22.12%, the crude fiber content is 20.43%, the total sugar content is 10.31%, the moisture content is 8.12%, and the viable count of the microbial bacterial agent is 3.5×10 8 cfu / g, the ratio of the crop straw with a particle size of ≤1.2mm to the total weight of the crop straw is 70%.

[0047] The production method of the above-mentioned straw bio-fermentation feed specifically comprises the following steps:

[0048] (1) Coarse crushing: take corn stalks after autumn harvest as raw materials, and crush the above raw materials to 2-3 cm for later use;

[0049] (2) Aging of stalks: Spray hydrogen peroxide evenly on the stalks prepared in step (1), and seal and store them for 7 days after spraying evenly, wherein the mass ratio of hydrogen peroxide to the stalks prepared in step (1) is 1:500;

[0050] (3) fine crushing: further pulverize the aging stalks obtained in step (2), pass through a 1.2mm sieve, get 3...

Embodiment 2

[0057] A straw fermented feed, wherein, the crude protein content is 18.32%, the crude fiber content is 25.15%, the total sugar content is 9.05%, the water content is 10.00%, and the viable count of the microbial bacterial agent is 2.7×10 9 cfu / g, the ratio of the crop straw with a particle size of ≤1.2mm to the total weight of the crop straw is 80%.

[0058] The production method of the above-mentioned straw bio-fermentation feed specifically comprises the following steps:

[0059] (1) Coarse crushing: take corn stalks after autumn harvest as raw materials, and crush the above raw materials to 2-3 cm for later use.

[0060] (2) Aging of stalks: Spray hydrogen peroxide evenly on the stalks obtained in step (1), and seal and store them for 4 days after spraying evenly, wherein the mass ratio of hydrogen peroxide to the stalks prepared in step (1) is 2:500;

[0061] (3) Fine crushing: further pulverize the crop stalks prepared in step (2), pass through a 1.2mm sieve, take 400k...

Embodiment 3

[0068] A straw bio-fermented feed, wherein the crude protein content is 22.31%, the crude fiber content is 23.41%, the total sugar content is 9.32%, the water content is 12.22%, and the viable count of the microbial bacterial agent is 5.7×10 9 cfu / g, the ratio of the crop straw with a particle size of ≤1.2mm to the total weight of the crop straw is 90%.

[0069] The production method of the above-mentioned straw bio-fermentation feed specifically comprises the following steps:

[0070] (1) Coarse crushing: the rice stalks after the autumn harvest are taken as raw materials, and the above raw materials are crushed to 2-3 cm for later use.

[0071] (2) Aging of stalks: Spray hypochlorous acid evenly on the stalks obtained in step (1), and seal and store them for 5 days after spraying evenly, wherein the mass ratio of hydrogen peroxide to the stalks prepared in step (1) is 2:500;

[0072] (3) Fine crushing: the crop stalks prepared in step (2) are further pulverized, passed thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com