Low-carbon nitrate wastewater efficient purification device system based on mixed matrix and purification treatment method

A purification device, mixed substrate technology, applied in special compound water treatment, polluted groundwater/leachate treatment, anaerobic digestion treatment, etc. and other problems, to achieve the effect of reducing follow-up processing costs, reducing operating costs, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

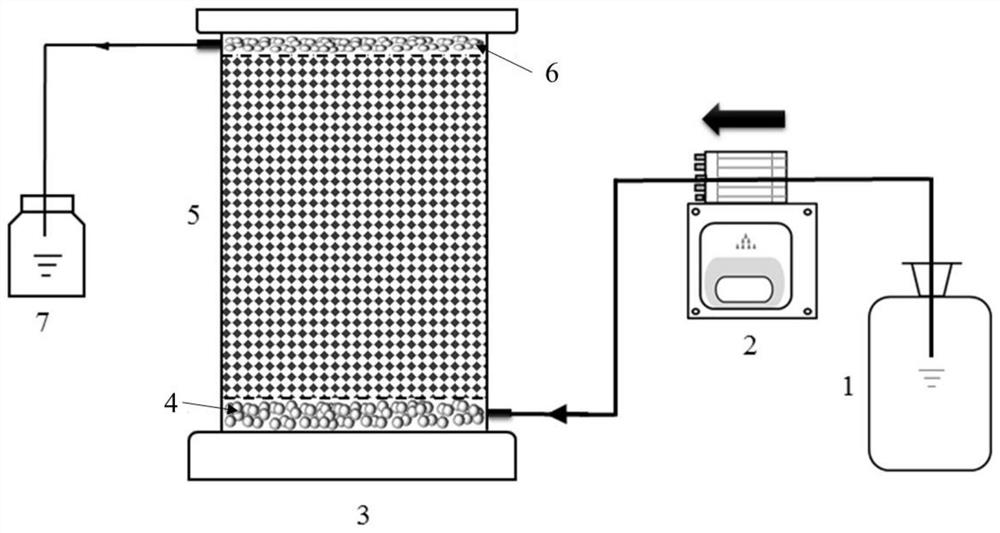

[0065] This embodiment provides a figure 1 The low-carbon nitrate wastewater high-efficiency purification device system based on mixed substrates shown, the device system includes: a water supply unit, a purification device 3 and an effluent collection unit connected in sequence;

[0066] Inside the purification device, a water distribution layer 4, a high-efficiency mixed matrix layer 5 and a support layer 6 are sequentially arranged in an upward direction perpendicular to the ground;

[0067] The filling medium of the high-efficiency mixed matrix layer 5 includes low-valent sulfur mixture and oyster shells.

[0068] The water supply unit includes a waste water storage bottle 1 and a feed pump 2 connected in sequence; the feed pump 2 is connected to the feed port at the bottom of the purification device 3; the feed pump 1 is a peristaltic pump.

[0069] The effluent collecting unit includes a effluent collecting bottle 7; the effluent collecting bottle 7 is a brown glass bot...

Embodiment 2

[0074] This embodiment provides a low-carbon nitrate waste water high-efficiency purification device system based on mixed substrates. The device system replaces the filling medium of the water distribution layer 4 and the support layer 6 with quartz sand with an average particle size of 3 cm. All the same as in Example 1.

Embodiment 3

[0076] This embodiment provides a low-carbon nitrate waste water high-efficiency purification device system based on mixed substrates. The device system replaces the filling medium of the water distribution layer 4 and the support layer 6 with quartz sand with an average particle size of 5 cm. All the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com