Toughening agent with core-shell structure, preparation method and application of toughening agent in preparation of oil-resistant high-toughness PC alloy

A technology of core-shell structure and toughening agent, which is applied in the field of oil-resistant high-toughness PC alloy and its preparation, to achieve the effect of lasting fragrance, ensuring heat resistance and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

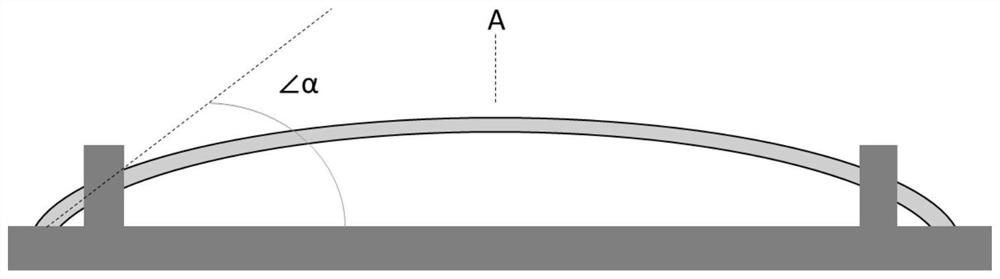

Image

Examples

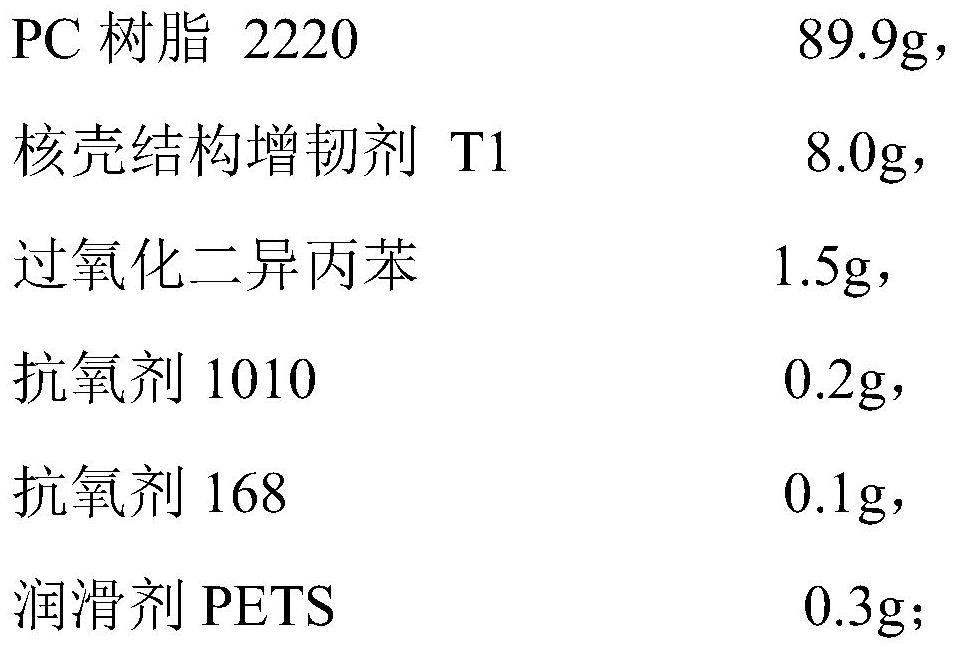

Embodiment 1

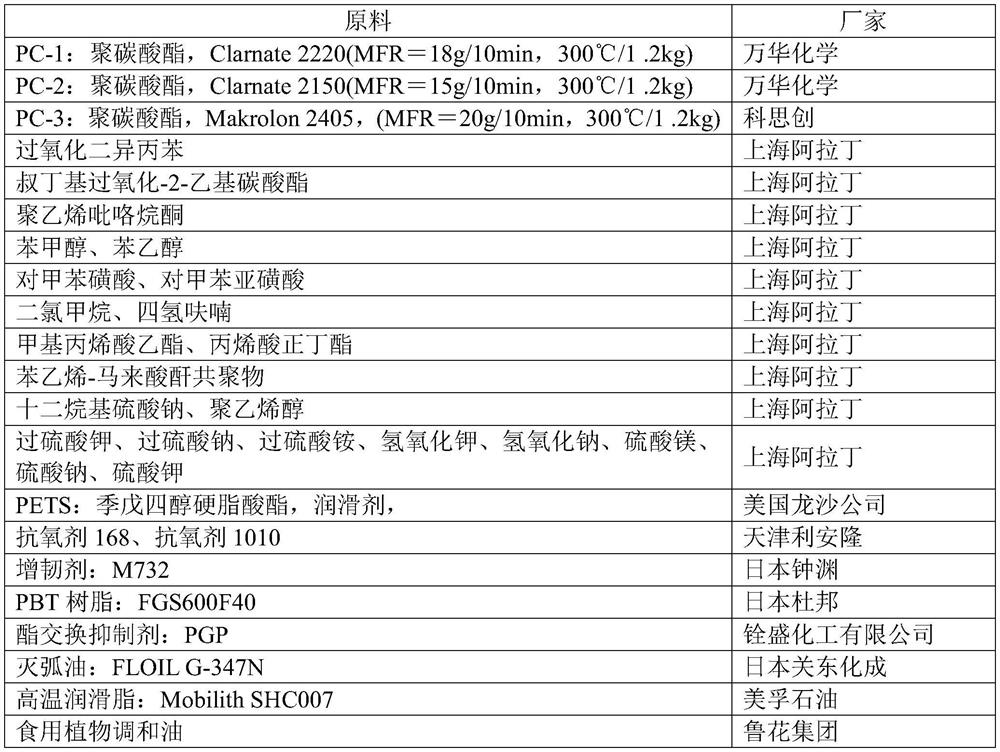

[0102] Prepare core-shell structure toughening agent (T1), the steps are:

[0103] 1) Add 180g of tetrahydrofuran, 30g of polyvinylpyrrolidone (molecular weight: 10000) and 30g of benzyl alcohol into a 1000ml three-necked flask equipped with a stirrer, heat up to 40°C, add 0.4g of p-toluenesulfonic acid, stir and condense for 6 hours, and the reaction ends Finally, control the temperature at 80°C, add 0.3 g of triethylamine dropwise to quench the reaction, stir until all solids are precipitated, filter with suction, and dry to obtain aryl polyvinylpyrrole ketal;

[0104] 2) Add 10g of deionized water and 0.5g of sodium lauryl sulfate to a 1000ml three-necked flask, raise the temperature to 60°C, add 5g of methyl methacrylate and 1g of potassium persulfate, perform a polymerization reaction at 60°C for 3 hours, and then use 0.5 h Add 52g of methyl methacrylate, sodium lauryl sulfate, and water mixture (the mixing quality is 10g, 2g, 40g), and perform two-stage polymerization re...

Embodiment 2

[0110] Prepare core-shell structure toughening agent (T2), the steps are:

[0111] 1) Add 150g of dichloromethane, 40g of polyvinylpyrrolidone (molecular weight: 20,000) and 35g of phenylethyl alcohol into a 1000ml three-neck flask equipped with a stirrer, heat up to 60°C, add 0.2g of p-toluenesulfinic acid, and stir for 2 hours for condensation reaction After the reaction, the temperature was controlled at 60°C, and 0.6 g of triethylamine was added dropwise to quench the reaction, stirred until all solids were precipitated, suction filtered, and dried to obtain aryl polyvinylpyrrole ketal;

[0112] 2) Add 30g of deionized water and 1g of sodium dodecylsulfonate to a 1000ml three-neck flask, raise the temperature to 70°C, add 5g of ethyl methacrylate and 0.5g of sodium persulfate, perform a polymerization reaction at 70°C for 2 hours, and then use Add dropwise 93g of ethyl methacrylate, sodium dodecylsulfonate, and water mixture (mixing mass: 20g, 3g, 70g) in 0.8h, and perform...

Embodiment 3

[0117] Prepare core-shell structure toughening agent (T3), the steps are:

[0118] 1) Add 140g of toluene, 50g of polyvinylpyrrolidone (molecular weight: 30,000) and 40g of phenylpropanol into a 1000ml three-neck flask equipped with a stirrer, heat up to 80°C, add 0.8g of p-toluenesulfinic acid, and stir the condensation reaction for 4h. After the reaction, control the temperature at 40°C, dropwise add 0.9 g of triethylamine to quench the reaction, stir until all solids are precipitated, filter with suction and dry to obtain aryl polyvinylpyrrole ketal;

[0119] 2) Add 30g of deionized water and 1.5g of sodium dodecylbenzenesulfonate into a 1000ml three-necked flask, raise the temperature to 80°C, add 8g of ethyl acrylate, 2g of ammonium persulfate, perform a polymerization reaction at 80°C for 4 hours, and then use 1h Add 130g of ethyl acrylate, sodium dodecylbenzene sulfonate, and water mixture (mixing mass: 27g, 3g, 100g) dropwise, and perform two-stage polymerization react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap