Acrylate coating for improving oxygen barrier property of PET (Polyethylene Terephthalate) film

An acrylate and oxygen barrier technology, applied in the direction of coating, etc., can solve the problems of high brittleness, poor coating adaptability, and difficulty in dissolving the coating, and achieve the effect of increasing the interaction force and good barrier effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

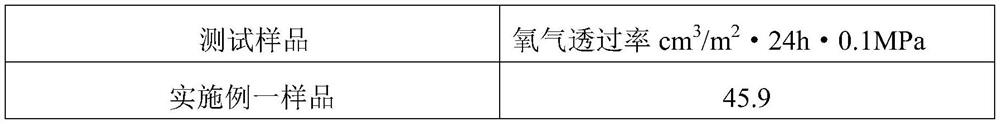

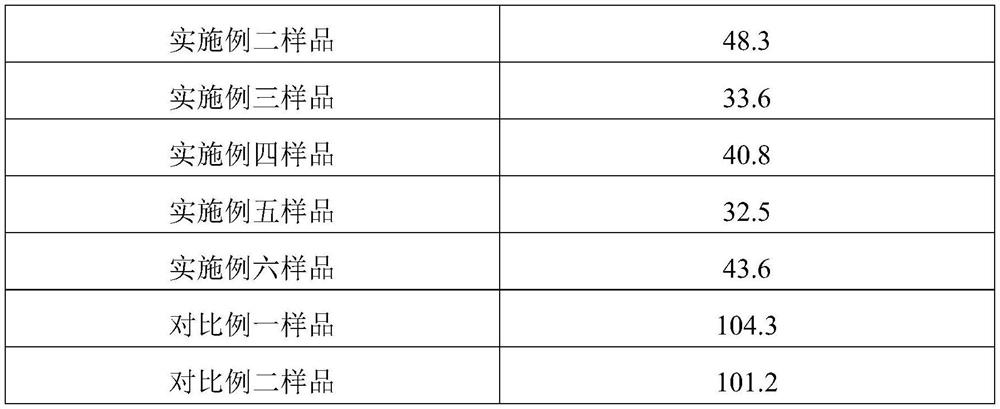

Examples

Embodiment 1

[0022] Polymerize 25g of isobornyl methacrylate, 12.5g of butyl acrylate, 1g of maleic anhydride, 0.2g of benzoyl peroxide and 61.3g of propyl acetate to obtain an acrylate coating.

[0023] The acrylate coating is coated on the PET base film and then dried and cured.

Embodiment 2

[0025] 60g of styrene, 2.5g of ethyl acrylate, 6.5g of fumaric acid, 1g of azobisisobutyronitrile, and 30g of methyl ethyl ketone were polymerized to obtain an acrylate coating.

[0026] The acrylate coating is coated on the PET base film and then dried and cured.

Embodiment 3

[0028] 30g of methyl methacrylate, 7.5g of methyl acrylate, 20g of maleic acid, 0.5g of benzoyl peroxide, and 42g of N-methylpyrrolidone were polymerized to obtain an acrylate coating.

[0029] The acrylate coating is coated on the PET base film and then dried and cured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com