Surfactant system with high foam performance and ultralow oil/water interfacial tension and application thereof

A surfactant and water interface technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of foam not resistant to oil and low interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 constructs surfactant system

[0041] According to the mole fraction ratio of SDS / DTAB is 0.6 / 0.4, weigh the required amount of two surfactants to prepare a binary mixture, then mix this binary mixture with nonionic surfactant APG to form a ternary mixture (the mole fraction of APG in the ternary mixture α n 0.1 to 0.7). That is, the mole fraction ratio of SDS / DTAB / APG in the ternary mixture is (0.6×(0.3-0.9)):(0.4×(0.3-0.9)):(0.1-0.7).

Embodiment 2

[0042] The performance measurement of embodiment 2 different surfactant systems

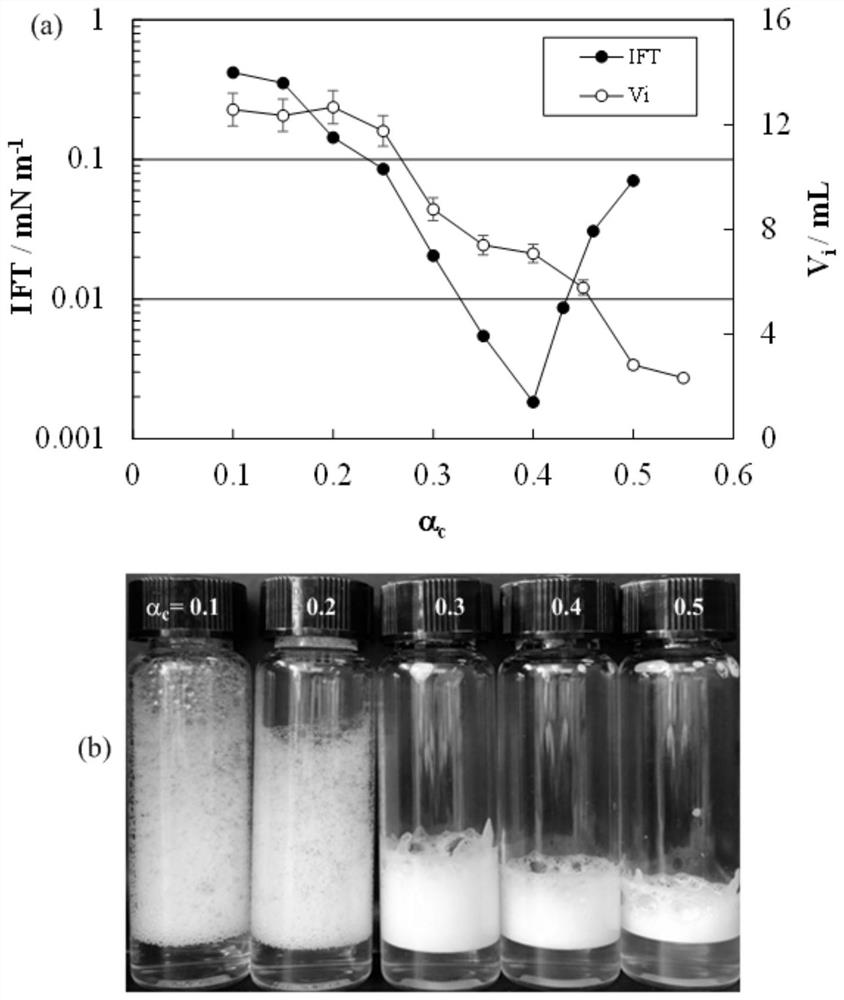

[0043] Dissolve the mixture in Daqing formation water to make a solution, or make each component into an aqueous solution and then mix them in proportion (the mixing order has no effect), the total concentration is set at 5mM, and the interface between the solution and Daqing crude oil is measured at 45°C tension and foaming properties, results such as image 3 and shown in Table 1. image 3 (a) shows that when the molar fraction of APG is 0.1-0.7, ultra-low interfacial tension can be obtained.

[0044] Take 2.5mL of the solution, put it in a 15mL glass bottle, shake it by hand at 45°C, shake it up and down 20 times, and record the initial foam volume (V i ), and take photos of the foam appearance after 5 minutes, the result is as follows image 3 (a) and (b), shown in Table 1.

[0045] It can be seen that with α n increase, V i increase, at α n = 0.4 to reach the maximum (12mL), and then ...

Embodiment 3

[0048] The performance measurement of the surfactant system of embodiment 3 different concentrations

[0049] The surfactant system consists of the following components: 0.36 mole fraction of anionic surfactant SDS, 0.24 mole fraction of cationic surfactant DTAB, and 0.4 mole fraction of nonionic surfactant APG.

[0050] The fixed composition is SDS / DTAB / APG=0.36 / 0.24 / 0.4, and the total concentration (C t ), measure the interfacial tension and the initial foaming volume (2.5mL solution is placed in the glass bottle of 15mL to foam by hand) respectively with Daqing crude oil, the result is as follows Figure 4 (a) and (b) shown. It can be seen that in the range of 2-7mM total concentration, the interfacial tension of crude oil / formation water can be reduced to ultra-low, while the initial bubble volume increases with the increase of total concentration, and tends to a plateau after the total concentration reaches 7mM (V i >12mL).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com