Cyclic ortho ester fuel additive

a fuel additive and cyclic ortho ester technology, applied in the field of liquid hydrocarbons, can solve the problems of affecting the reactivity of the fuel additive, so as to reduce the freezing point of water left, reduce corrosion, and increase the reactivity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

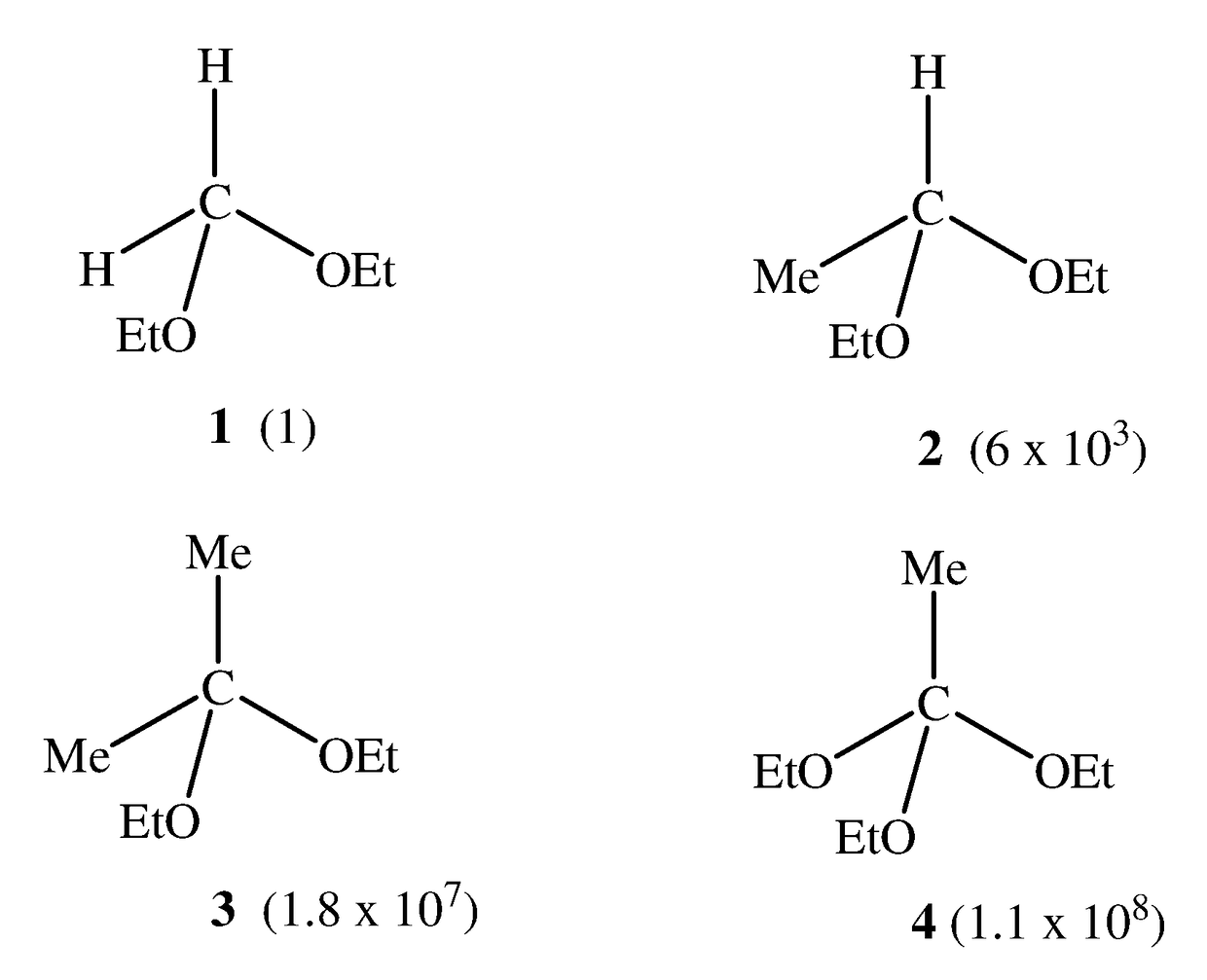

[0068]Acetals, ketals, ortho esters and cyclic ortho esters have been generally known in the art, such as the paper by Santry 1998 Supra, and may be obtained from a number of commercially available source such as Sigma Aldrich.

EXPERIMENTAL SECTION

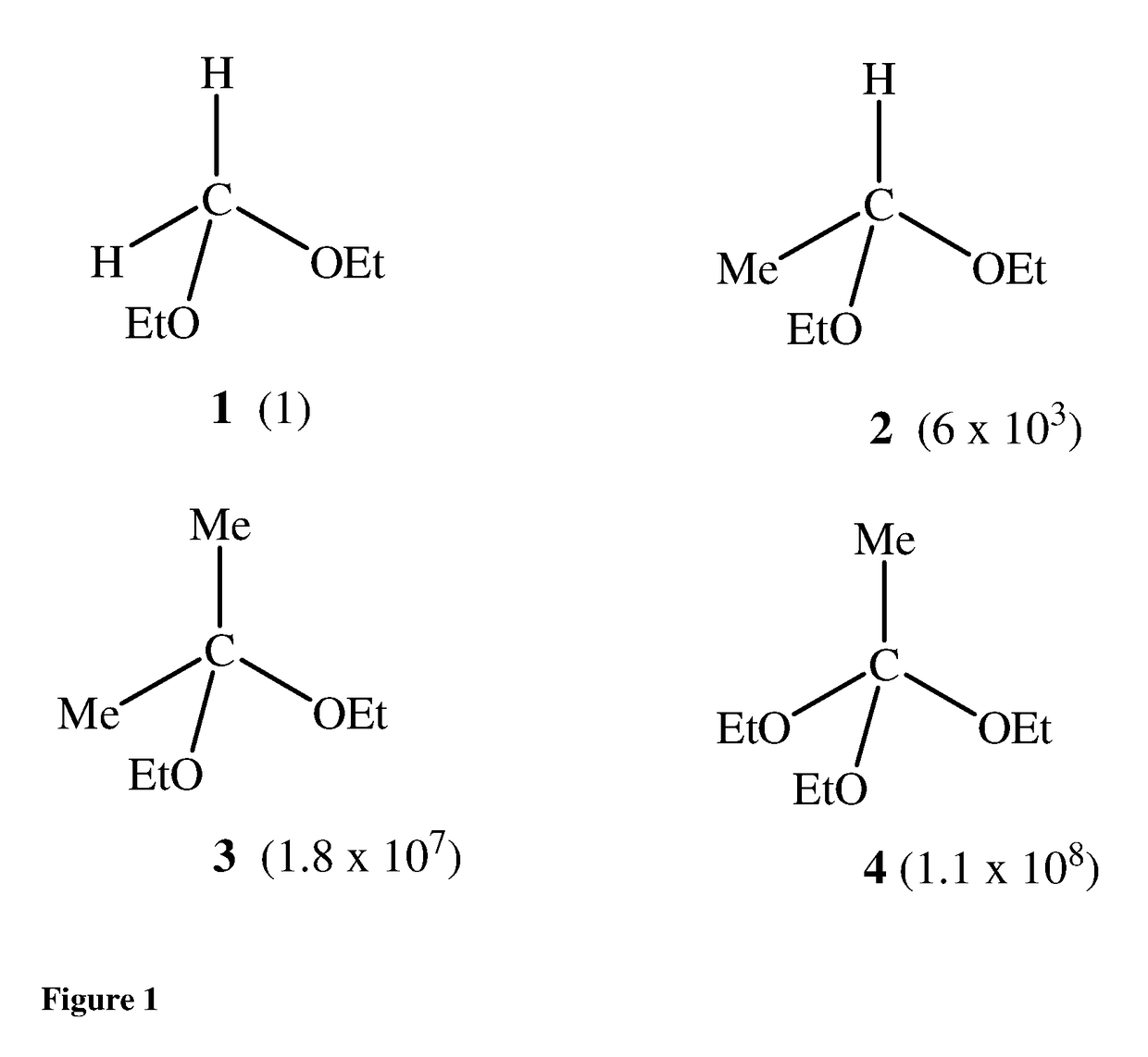

Experimental GC

[0069]The analyses were performed using an Agilent 5890 gas chromatograph equipped with a flame ionisation detector. The GC column used was of fused silica, HP-5MS, 30 m by 0.25 mm, with a helium flow rate of 1.5 mL / min. The temperature for the detector and injector was fixed at 250° C. The oven temperature used for the analysis was 80° C. for 4 minutes, then it was increased at 20° C. / min to 240° C. and held for 2 minutes.

[0070]Jet A-1, obtained by Air BP (Batch number BIS / HAL / 12 / 035K), was dried by storing it over 3 Å molecular sieve for at least 24 hours. Standards with different water concentrations were prepared by adding measured volumes of distilled water by SGE μL syringes to 20 ml of anhydrous Jet A-1, taking extra c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com