Emulsion for chlorine-acrylic metal protective paint as well as preparation method and application of emulsion

A chloropropene metal and metal protection technology, applied in anti-corrosion coatings, coatings, etc., can solve the problem of low salt spray resistance, and achieve the effect of low cost, good adhesion, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

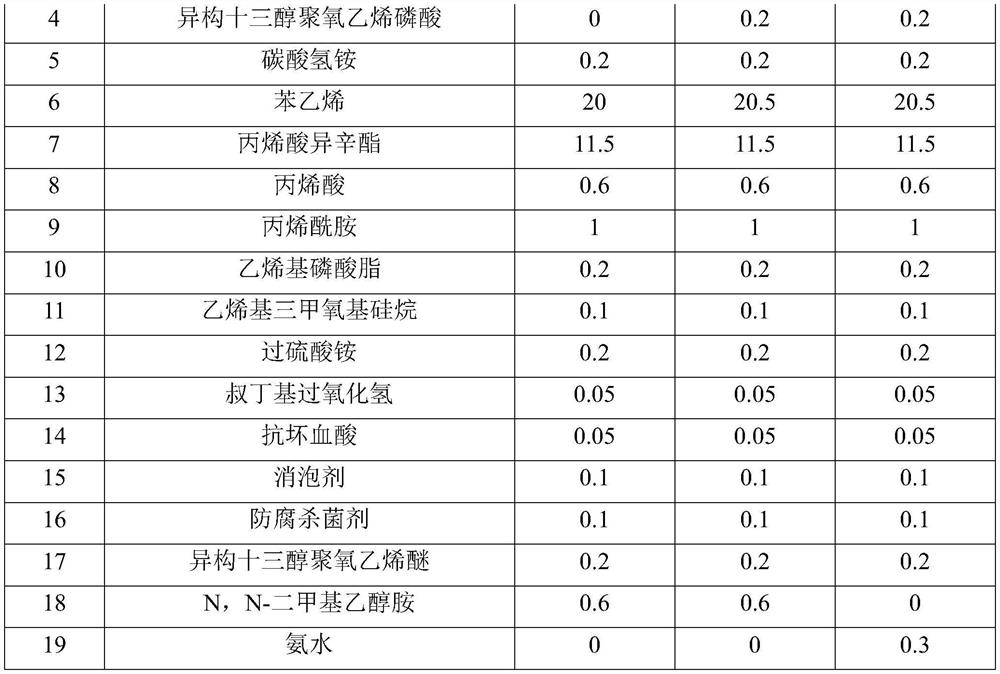

Embodiment 1

[0029] An emulsion for metal chloride propylene protective paint, in parts by weight, comprising 19.75 parts of deionized water, 0.2 part of ammonium bicarbonate, 0.35 part of ammonium dodecylbenzenesulfonate, 45 parts of polyvinyl chloride emulsion, 20 parts of styrene 11.5 parts of isooctyl acrylate, 1 part of acrylamide, 0.6 parts of acrylic acid, 0.2 parts of vinyl phosphate, 0.2 parts of ammonium persulfate, 0.1 parts of vinyltrimethoxysilane, 0.05 parts of tert-butyl hydroperoxide, ascorbic acid 0.05 part, 0.1 part of defoamer, 0.1 part of antiseptic and bactericide, 0.6 part of N, N-dimethylethanolamine, 0.2 part of isomeric tridecyl alcohol polyoxyethylene ether (9 EO),

[0030] Its preparation method comprises the following steps:

[0031] (1) take each component according to the raw material parts by weight of the emulsion for metal chloropropane protective paint;

[0032] (2) The deionized water of 40% formula quantity and isomerized polyoxyethylene tridecyl alcoho...

Embodiment 2

[0037] An emulsion for chloropropyl metal protective paint, comprising 19.25 parts by weight of deionized water, 0.2 part of ammonium bicarbonate, 0.15 part of ammonium dodecylbenzenesulfonate, 45 parts of polyvinyl chloride emulsion, 20.5 parts of styrene 11.5 parts of isooctyl acrylate, 1 part of acrylamide, 0.6 parts of acrylic acid, 0.2 parts of vinyl phosphate, 0.2 parts of ammonium persulfate, 0.1 parts of vinyltrimethoxysilane, 0.05 parts of tert-butyl hydroperoxide, ascorbic acid 0.05 part, 0.1 part of defoamer, 0.1 part of antiseptic and bactericide, 0.6 part of N, N-dimethylethanolamine, 0.2 part of isomeric tridecyl alcohol polyoxyethylene ether (9 EO),

[0038] Its preparation method comprises the following steps:

[0039] (1) take each component according to the raw material parts by weight of the emulsion for metal chloropropane protective paint;

[0040] (2) The deionized water of 40% formula quantity and isomerized polyoxyethylene tridecyl alcohol phosphoric a...

Embodiment 3

[0045] An emulsion for chloropropyl metal protective paint, comprising 19.55 parts by weight of deionized water, 0.2 part of ammonium bicarbonate, 0.15 part of ammonium dodecylbenzenesulfonate, 45 parts of polyvinyl chloride emulsion, 20.5 parts of styrene 11.5 parts of isooctyl acrylate, 1 part of acrylamide, 0.6 parts of acrylic acid, 0.2 parts of vinyl phosphate, 0.2 parts of ammonium persulfate, 0.1 parts of vinyltrimethoxysilane, 0.05 parts of tert-butyl hydroperoxide, ascorbic acid 0.05 part, 0.1 part of defoamer, 0.1 part of antiseptic and bactericide, 0.2 part of isomeric tridecyl alcohol polyoxyethylene ether (9 EO), 0.3 part of ammonia water;

[0046] Its preparation method comprises the following steps:

[0047] ((1) take each component according to the raw material parts by weight of the emulsion for the chloropropane protective paint;

[0048] (2) The deionized water of 40% formula quantity and isomerized polyoxyethylene tridecyl alcohol phosphoric acid, the ammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com