Soaping agent for continuous dyeing and application thereof

A technology of soaping agent and soaping liquid, which is applied in the field of continuous dyeing of reactive dyes, can solve the problems of energy consumption, time consumption, prolonging soaping time, high consumption, etc., and achieve high-efficiency soaping, remarkable water-saving effect, and improved The effect of energy saving and emission reduction benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Soaping agent formula: methylnaphthalenesulfonic acid formaldehyde condensate 1.0%, sodium sulfate 3.0%, pyrrolidone 1.0%, sodium dithionite 15%, sodium persulfate 15%, citric acid 20% and sodium carboxymethylcellulose 45% .

[0039] Dyeing with reactive dyes: After padding the corduroy fabric with reactive blue SNE 25g / L, the liquid retention rate was 85%, and the color was fixed by steaming at 102°C for 3min.

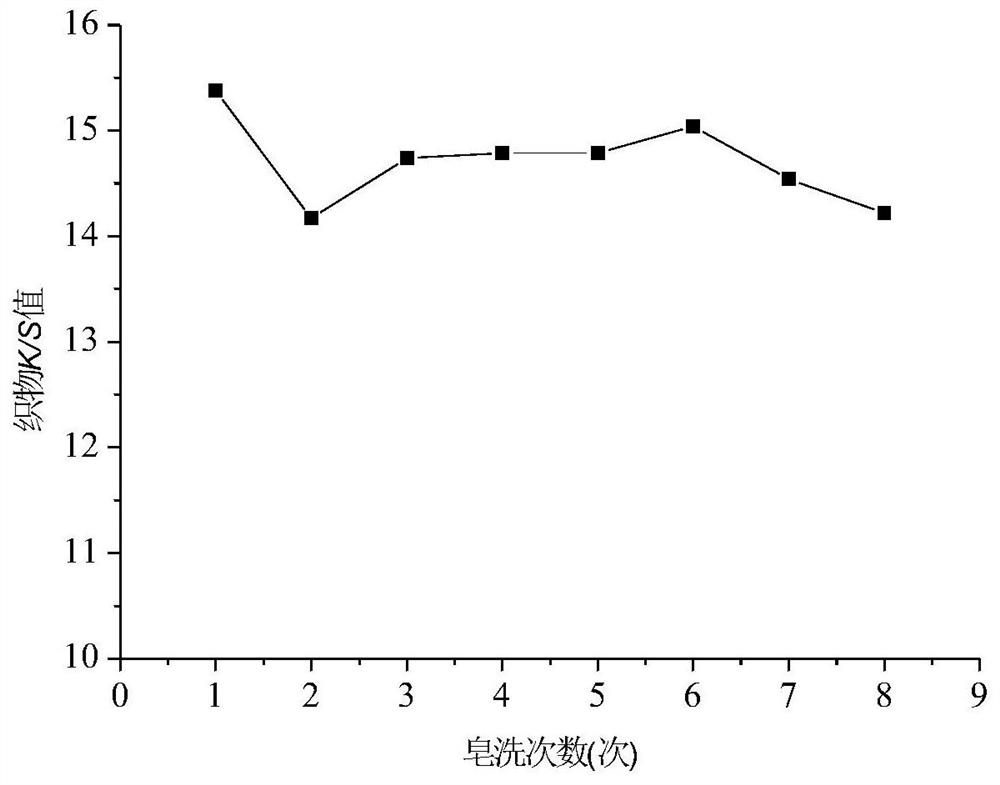

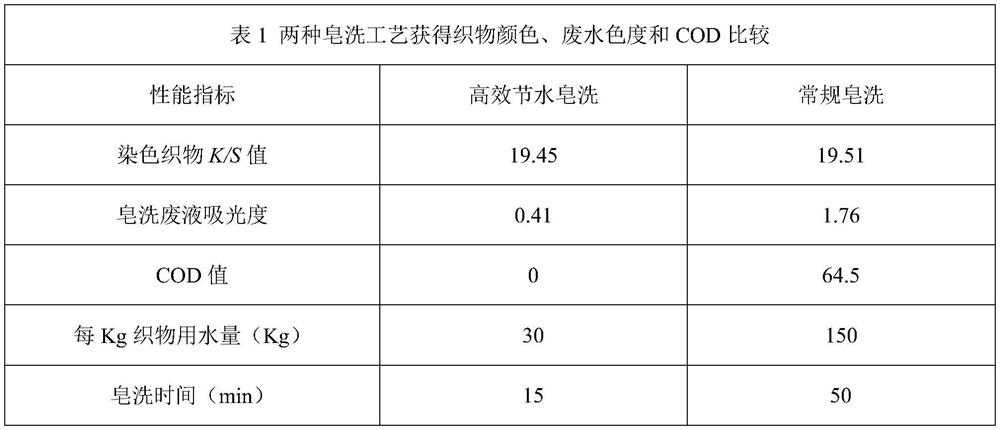

[0040] The soaping process of the present invention: after fixing the color, the fabric is directly placed in the soaping liquid at 85° C. for 15 minutes, the bath ratio is 1:30, and the concentration of the soaping agent is 3%. There is no need to wash after soaping, and the fabric is dried directly after being taken out, and the soaping liquid is recycled and reused.

[0041] Conventional soaping process: After fixing the color, the fabric is washed in cold water for 5 minutes at a liquor ratio of 1:30 → washed in hot water at 50-60°C for 5 minutes → soaped ...

Embodiment 2

[0047] Soaping agent formula: pyrrolidone 1.5%, sodium sulfate 3.0%, methylnaphthalenesulfonic acid formaldehyde condensation 1.0%, sodium dithionite 15%, sodium persulfate 15%, sodium bisulfite 3%, citric acid 25% and carboxymethyl Sodium cellulose base 36.5%.

[0048] Dyeing with reactive dyes: After padding the corduroy fabric with reactive blue SNE 25g / L, the liquid retention rate was 85%, and the color was fixed by steaming at 102°C for 3min.

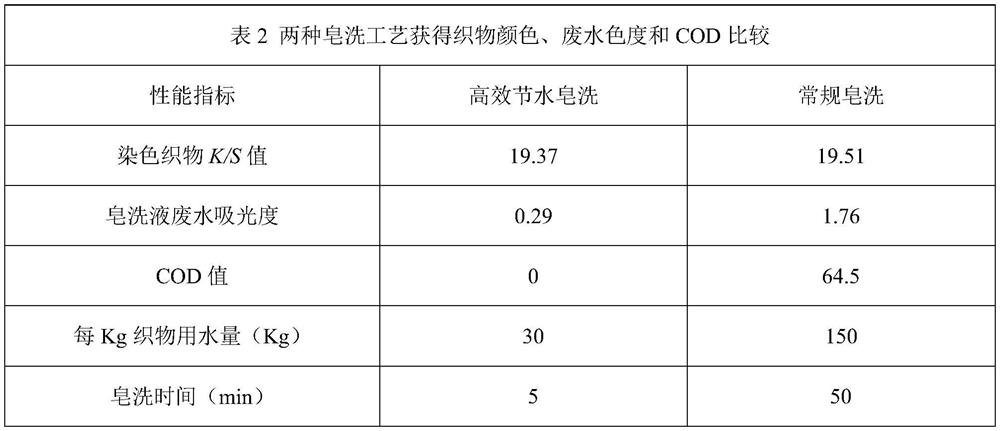

[0049] The soaping process of the present invention: after fixing the color, the fabric is directly placed in a soaping solution at 100° C. for 1 min, and the concentration of the soaping solution is 1%. After the soaping treatment, no washing is required, and the fabric is taken out and dried directly. The obtained fabric color parameters, chromaticity of wastewater and COD value are shown in Table 2.

[0050]

[0051] Table 2 shows that the apparent color depth K / S value of the dyed fabric obtained by the high-efficiency wate...

Embodiment 3

[0053] Soaping agent formula: methylnaphthalenesulfonic acid formaldehyde condensate 1.5%, sodium sulfate 3.0%, pyrrolidone 1.5%, sodium dithionite 15%, sodium metabisulfite 10%, sodium persulfate 10%, citric acid 15% and carboxymethyl Sodium Cellulose 44%.

[0054] Dyeing with reactive dyes: After padding the corduroy fabric with reactive red 3BS 60g / L, the liquid retention rate was 85%, and the color was fixed by steaming at 102°C for 5min.

[0055] The soaping process of the present invention: after fixing the color, the fabric is directly placed in a soaping solution at 100° C. for 5 minutes, and the concentration of the soaping agent is 5%. After the soaping treatment, no washing is required, and the fabrics are taken out and dried directly. The obtained fabric color parameters, wastewater chromaticity and COD values are shown in Table 3.

[0056]

[0057]

[0058] Table 3 shows that the apparent color depth K / S value of the dyed fabric obtained by the high-effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com