Soft nerve probe based on mixed silica gel and preparation method thereof

A silicone and nerve technology, applied in the field of biomedical electricity, can solve the problems of lack of elastic polymer substrate modulus, affecting the ductility of nerve probes, and inapplicability of soft nerve probes, etc., to achieve stable and reliable electrochemical performance, guaranteeing The electrochemical performance and morphology are kept intact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention provides a soft nerve probe based on mixed silica gel and a preparation method thereof, which are improved based on common electrode substrate materials, thereby forming an elastic hybrid silica gel base with adjustable Young's modulus, and by depositing a parylene film , the wrinkles are formed spontaneously, and the morphology will not change with the intervention of the subsequent process, which effectively improves the specific surface area of the soft nerve probe electrode point and ensures stable and reliable electrochemical performance; The polymer is etched by oxygen plasma reaction The thin film obtains the serpentine interconnect structure, and the laser cutting obtains the outline of the soft nerve probe, which maintains the high ductility of the soft nerve probe.

[0047] A soft nerve probe based on hybrid silica gel, the soft nerve probe has a serpentine interconnection structure, comprising an elastic hybrid silica gel base 1, a bottom polym...

specific Embodiment 1

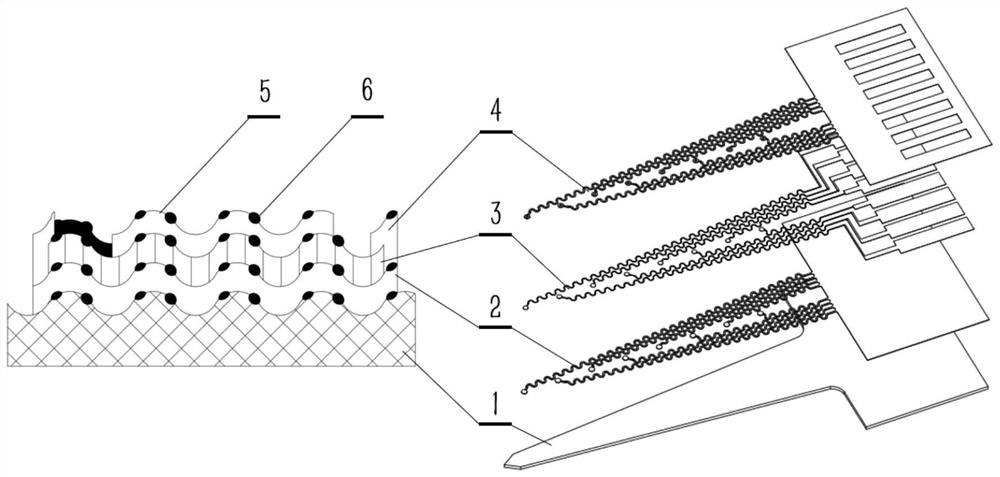

[0074] like figure 1 As shown, this embodiment provides a preferred structural schematic diagram of a soft nerve probe based on hybrid silica gel, wherein the soft nerve probe is composed of an elastic hybrid silica gel base 1, a bottom polymer insulating layer 2, a metal conductive layer 3, and a top polymer layer. The material packaging layer 4, the labyrinth type wrinkle pattern 5, and the bump type wrinkle pattern 6 are composed of six parts.

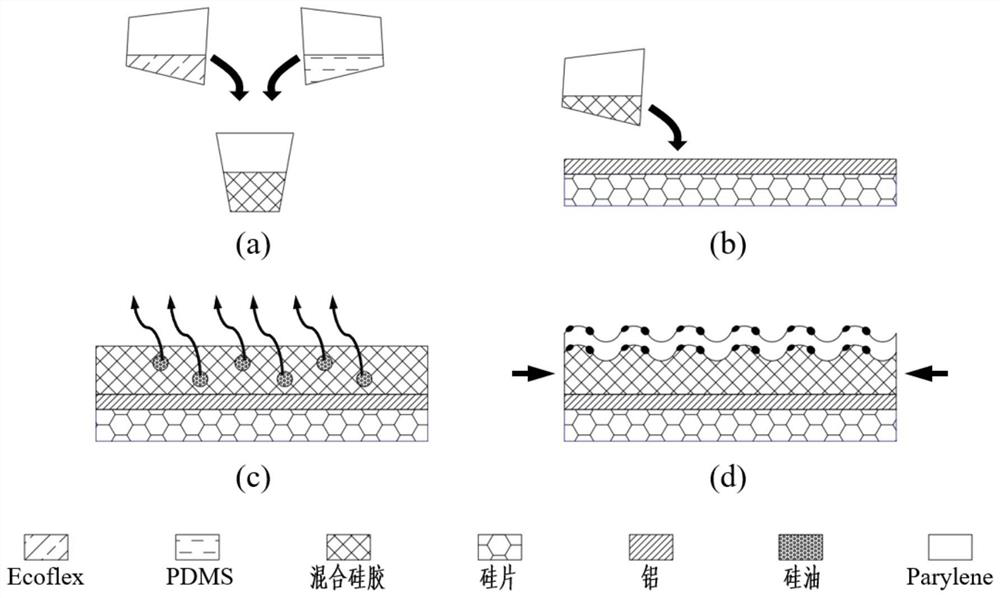

[0075] like figure 2As shown, this embodiment provides a schematic diagram of a composite wrinkle microstructure formed based on mixed silica gel. The elastic mixed silica gel base 1 is to mix two or more kinds of silica gels and spin-coat, and before curing, add silicone oil and extract to obtain the elastic mixed silica gel base 1. The mass percentage of the mixed silicone oil is the elastic mixed silica gel base and the silicone oil. 30% of the total mass. A first polymer film was deposited on the elastic hybrid silicone subs...

Embodiment 2

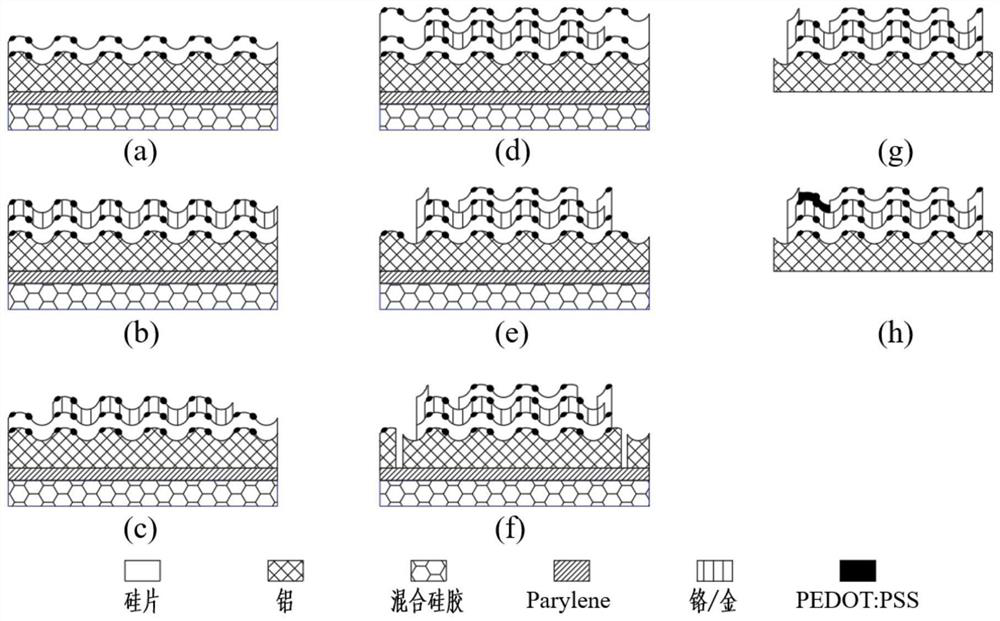

[0096] This example provides a method for preparing a soft nerve probe based on mixed silica gel. The specific implementation steps are the same as those in Example 1. The difference is that in S3, a mixture of PDMS:Ecoflex=1:4 is used. The obtained elastic hybrid silica gel substrate, by depositing Parylene C on its surface, can obtain different wrinkle morphologies from the elastic hybrid silica gel substrate obtained by mixing PDMS:Ecoflex=1:2.

[0097] like Figure 4 As shown, a comparison of the hybrid silica-based soft nerve probes prepared by the above method (such as Figure 4 (c)) and the deposition of Parylene C on a single PDMS without pretreatment with silicone oil (as in Figure 4 (a)), and the deposition of Parylene C on a single PDMS pretreated with silicone oil (as Figure 4 In the wrinkle pattern obtained in (b), it can be seen that the amplitude of the wrinkle increases significantly, and the maximum amplitude of Parylene C deposited on PDMS without silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com