Composite hydrogel for promoting wound healing and preparation method and application thereof

A composite hydrogel and wound healing technology, applied in medical science, bandages, etc., to achieve high biological activity, accelerate healing, and promote healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

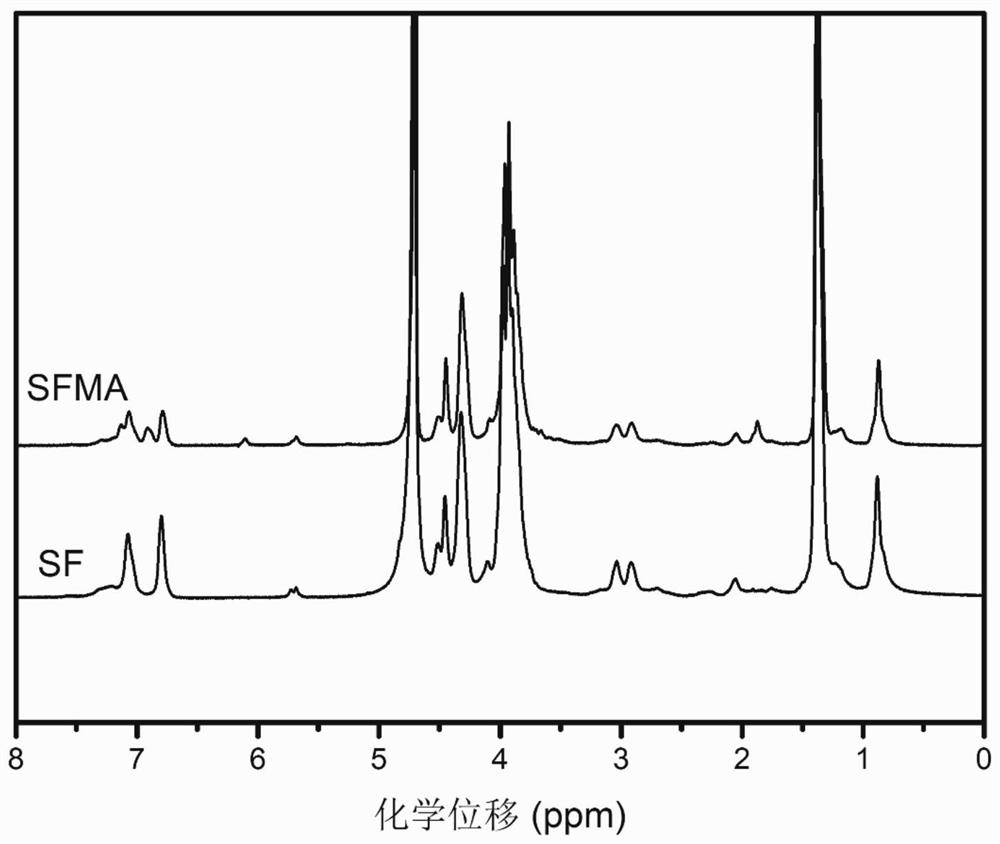

[0031] A method for preparing silk fibroin methacryl (SFMA), comprising the following steps:

[0032] Submerge 10g of cocoons in 1L of 0.05M Na 2 CO 3 The solution was boiled at 100°C for 30 minutes, and washed several times with distilled water to obtain degummed silk fibroin. Then, the degummed silk fibroin (SF) was dried in a drying oven for 36 hours. To obtain SFMA, 10 g of degummed SF was dissolved in 9.3 M lithium bromide (LiBr) solution at 60 °C for 1 h, stirred with a magnetic stirrer, and then 6 mL of glycidyl methacrylate (GMA) was slowly added dropwise. After 8 hours of reaction, the solution was filtered through a magic filter cloth to remove salt, and dialyzed with distilled water for 7 days using a dialysis bag. The resulting SFMA solution was frozen at −80 °C for 12 h and then freeze-dried for 36 h to obtain spongy SFMA.

[0033] In fact, the ratio of the weight of the degummed silk fibroin to the volume of the glycidyl methacrylate can be 1: (0.3-0.9) g / ml....

Embodiment 2

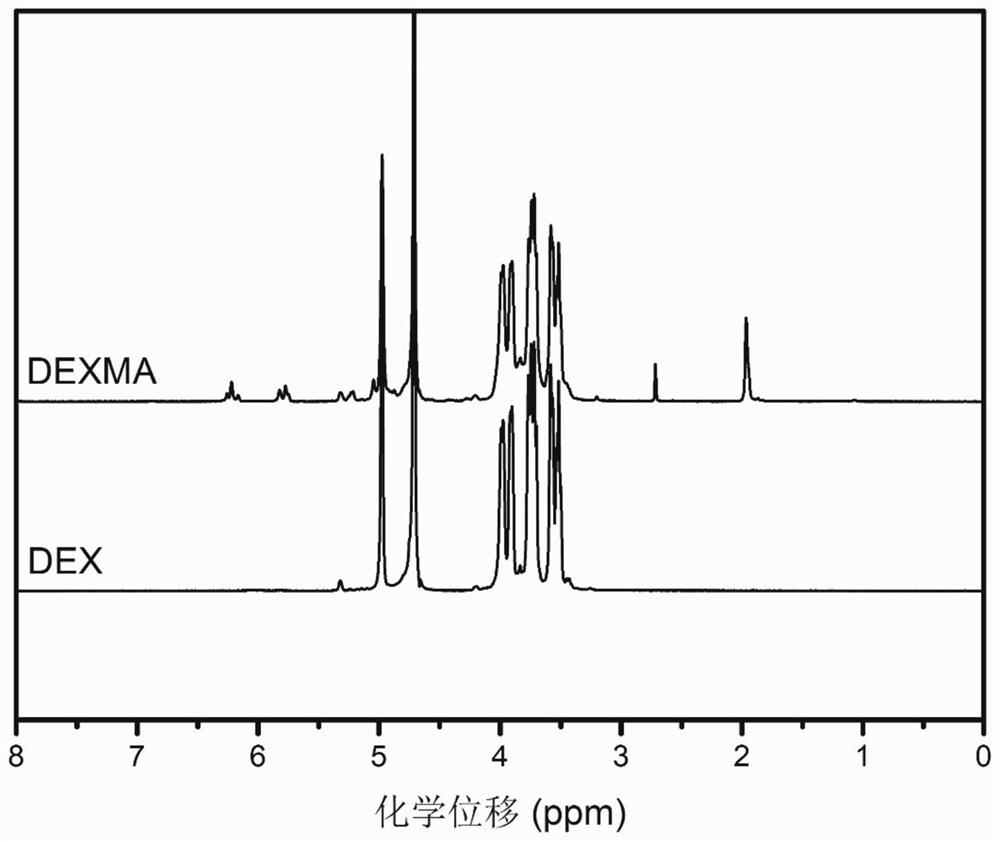

[0035] A method for preparing dextran methacryl (DEXMA), comprising the following steps:

[0036] Dissolve 10 g of dextran in 100 mL of anhydrous DMSO at room temperature and stir for 1 h. Then 2 g of 4-dimethylaminopyridine (DMAP) was added to the above solution. After stirring for 1 hour, 3 mL of glycidyl methacrylate (GMA) was added. The reaction was carried out for about 48 h at room temperature under closed, dark and continuous stirring. The reaction mixture was then dialyzed against a dialysis bag for about 3 days. The resulting DEXMA solution was frozen at -80°C for 12 hours and then freeze-dried for 36 hours to obtain sponge-like DEXMA.

[0037] In fact, the weight ratio of the dextran to the glycidyl methacrylate may be 1: (0.1-0.6) g / ml.

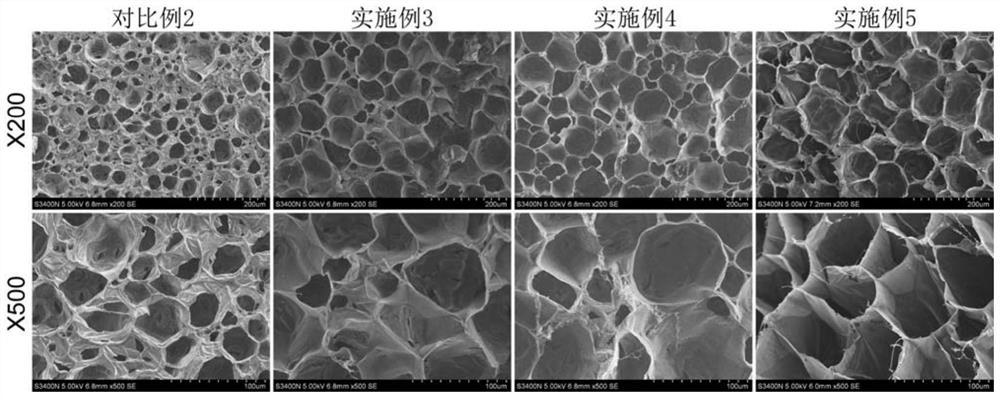

Embodiment 3

[0039] The preparation method of 10%SFMA / 1%DEXMA hydrogel comprises the following steps:

[0040] The SFMA (10wt.%) prepared by 0.2g embodiment 1 and the DEXMA (1wt.%) prepared by 0.02g embodiment 2 and 0.002gLAP photoinitiator (0.1wt.%) were dissolved in 2mL deionized water, and the ultraviolet light was irradiated for 30s , namely 10% SFMA / 1% DEXMA hydrogel.

[0041] In fact, based on the volume of deionized water, the amount of methacrylylated silk fibroin SFMA can be 5w / v%-15w / v%, and the above-mentioned ultraviolet irradiation time can be 10-120s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com