Silver selenide thermoelectric composite film and preparation method and application thereof

A technology of composite thin film and silver selenide, which is applied in the manufacture/processing of thermoelectric devices, materials for lead-out wires of thermoelectric devices, coatings, etc., can solve the problems of low output power and large internal resistance of films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

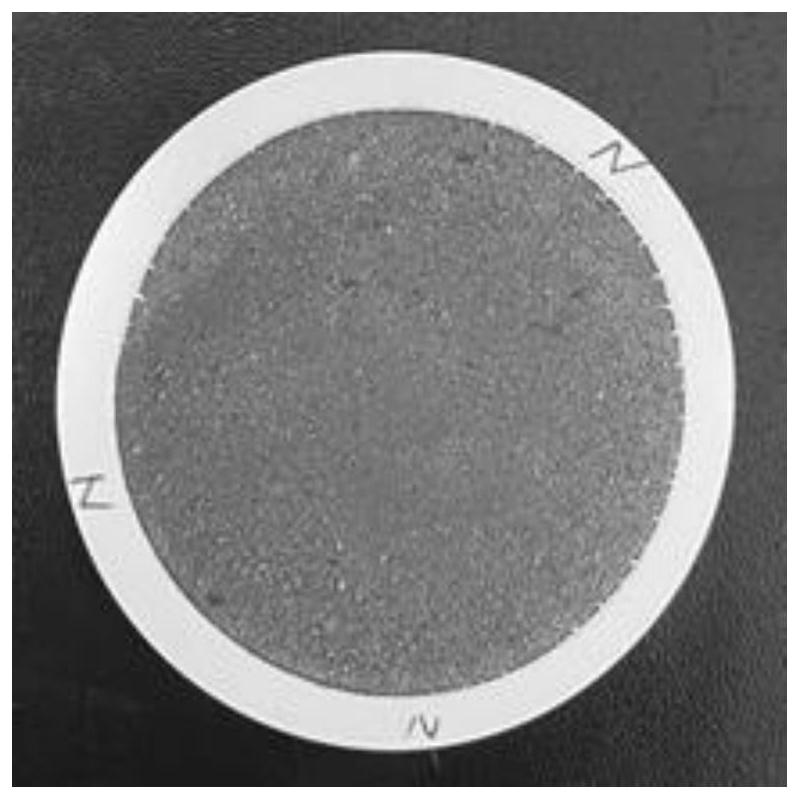

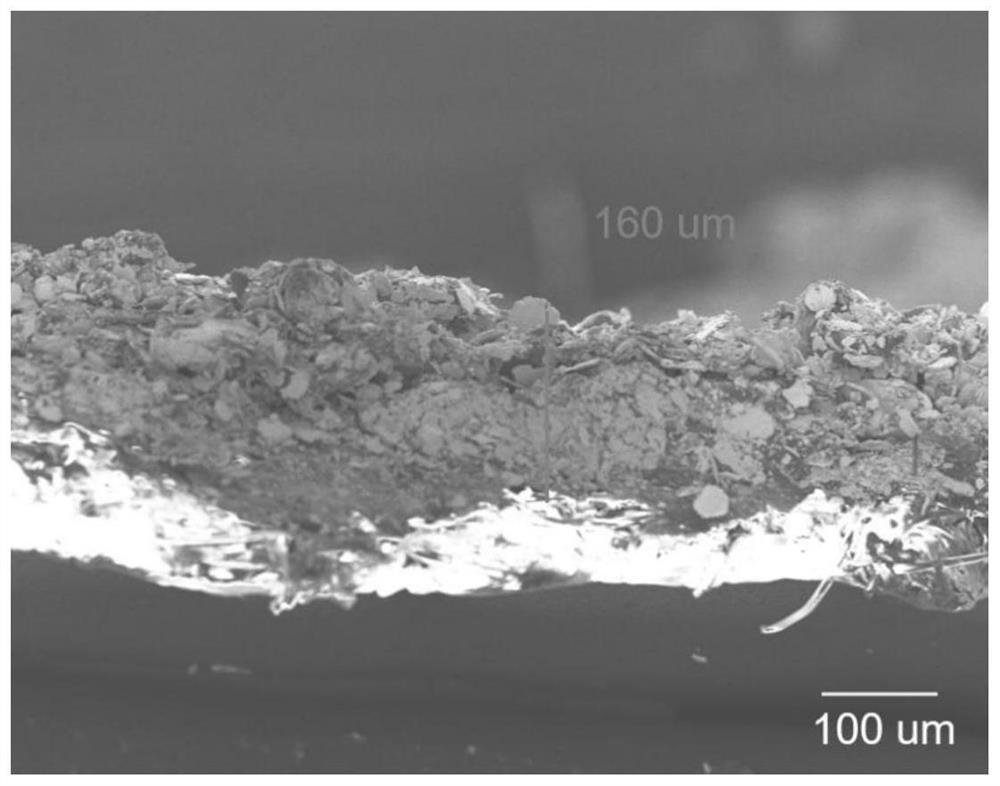

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a silver selenide thermoelectric composite film, comprising the following steps:

[0024] (1) Silver selenide, solvent, binding agent and PEDOT:PSS aqueous solution are mixed and pulverized to obtain a dispersion;

[0025] (2) Deposit the dispersion obtained in the step (1) on the substrate, and then dry to obtain a silver selenide thermoelectric composite thin film.

[0026] Unless otherwise specified, the present invention has no special limitation on the source of each component, and commercially available products or products prepared by conventional preparation methods well known to those skilled in the art can be used.

[0027] The invention mixes the silver selenide, solvent, binder and PEDOT:PSS aqueous solution and then pulverizes to obtain the dispersion liquid.

[0028] In the present invention, the particle size of the silver selenide is preferably 1-50 μm, more preferably 5-40 μm, and most preferably 10-30 μm. ...

Embodiment 1

[0057] (1) Put 200 mg of silver selenide particles (10-100 μm) in a grinding bowl, add 2 mL of N-methylpyrrolidone, grind with a grinding rod until the solvent evaporates completely, then add 2 mL of N-methylpyrrolidone, repeat 4 times, A total of 20min, to obtain silver selenide powder (1 ~ 50μm);

[0058] (2) the silver selenide powder that step (1) obtains, 30mg sodium carboxymethyl cellulose, 0.5mL PEDOT:PSS aqueous solution (the total concentration of PEDOT and PSS is 15g / L, PEDOT:PSS is purchased from Aladdin platform, CAS No. 155090-83-8) and 25 mL of absolute ethanol (the mass ratio of silver selenide and sodium carboxymethylcellulose is 6.7:1, the mass ratio of silver selenide and PEDOT:PSS aqueous solution is 1 mg: 0.0025 mL , the quality of silver selenide and the volume ratio of absolute ethanol is 1mg:0.125mL) mixed, stirred with a glass rod for 10min, put into an ultrasonic cell pulverizer for pulverization, the power is 110W, the time is 30min, and the ultrasoni...

Embodiment 2

[0061] The quality of sodium carboxymethyl cellulose in step (2) of embodiment 1 is replaced as 40mg, and now the mass ratio of silver selenide and sodium carboxymethyl cellulose is 5:1, and other parameters are all identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com