Preparation process of silica gel magnetic ring

A preparation process and technology of silica gel, which is used in the manufacture of inductors/transformers/magnets, metal processing equipment, electrical components, etc., can solve problems such as high-frequency characteristics enhancement, and achieve high-frequency characteristics enhancement, wide application prospects, and good adhesion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

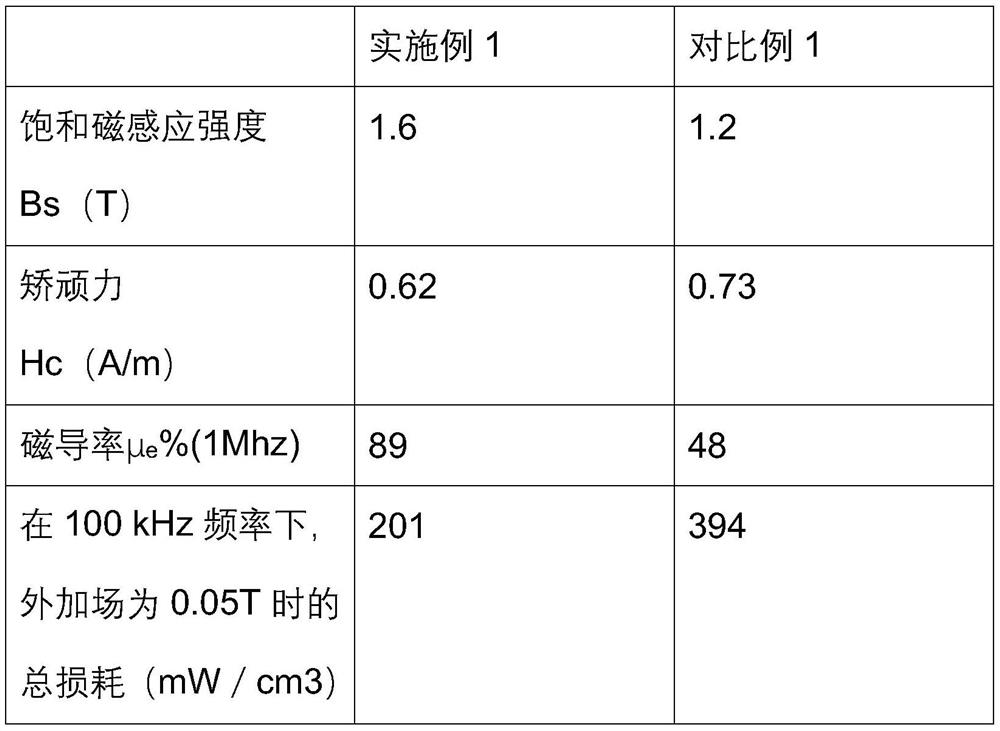

Examples

Embodiment 1

[0032]The preparation of described silica gel, comprises the steps:

[0033] (1) The silica gel includes the following components in parts by mass: 60 parts of methyl block room temperature vulcanized silicone rubber, 3.5 parts of MQ resin, 4.0 parts of fumed silica, 0.8 parts of coupling agent KH570, ethyl orthosilicate 0.6 parts, 0.3 parts of dibutyltin dilaurate;

[0034] (2) Add MQ resin dissolved in n-hexane, fumed silica, and coupling agent KH570 into the methyl block room temperature vulcanized silicone rubber, stir and mix on a high-speed disperser for 1 hour, after mixing evenly, put it in a vacuum drying oven, Dry at 30° C. to remove n-hexane, and vacuumize for 20 min to obtain a mixture;

[0035] (3) Add ethyl orthosilicate and dibutyltin dilaurate to the above mixture, stir and mix on a high-speed disperser for 30 minutes, vacuumize and defoam, inject into a mold, open the mold after curing, and take it out to obtain silica gel.

Embodiment 2

[0037] The preparation technology of silica gel magnetic ring comprises the steps:

[0038] (1) alloy ingot: the typical composition of the master alloy is (Fe 0.76 Si 0.09 B 0.1 P 0.05 ) 98.1 Nb 0.8 Cu 0.6 Tb 0.3 La 0.2 ; According to the above proportioning, weigh Fe, Si, Nb, FeB, Cu, Fe-P, Tb, La high-purity raw materials, Fe, Si, Nb, FeB, Cu, Fe-P, Tb, La high-purity raw materials Place in acetone / ethanol solution, remove surface oil and other organic matter by ultrasonic cleaning, and then dry; before smelting, first strictly check the cleanliness of the non-consumable vacuum arc melting furnace cavity, clean the furnace cavity, and then put Fe, Si, Nb , FeB, Cu, Fe-P, Tb, La high-purity raw materials are put into the crucible, and the low-melting and volatile raw materials are put into the crucible first; the furnace door is closed and the mechanical pump and the diffusion pump are used to evacuate in order to make the oxygen partial pressure reach 5x10 -2 Belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com