High-performance low-carbon aluminum alloy and preparation method

A carbon-aluminum alloy, high-performance technology, applied in the field of aluminum alloy materials, can solve problems such as unfavorable cost control, rare earth-rich phase precipitation restricting performance improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The second aspect provides a method for preparing the high-performance low-carbon aluminum alloy described in the first aspect, comprising:

[0046] S1: Proportion raw materials according to the required chemical composition, the raw materials are pure aluminum and other raw material master alloys;

[0047] S2: Preheating the raw materials;

[0048] S3: Melting and refining the preheated raw materials, pouring and cooling after all the raw materials are melted, to obtain aluminum alloy castings;

[0049] S4: The aluminum alloy casting is subjected to solution heat treatment, using a two-stage solution process: the temperature of the first solution treatment is 400-450°C, the time of the first solution treatment is 4-10h, and the temperature of the second solution solution is 500°C. ~510℃, the secondary solid solution treatment time is 8~20h;

[0050] S5: performing water quenching and artificial aging on the aluminum alloy casting after the solution heat treatment to ...

Embodiment 1

[0070] A high-performance low-carbon aluminum alloy, its chemical composition is calculated by mass percentage: Si 7.23%, Cu 3.38%, Mg 0.26%, Fe 0.39%, Mn 0.38%, Ti 0.02%, La 0.07%, the rest is Al and unavoidable impurities.

[0071] The preparation method of above-mentioned alloy, according to the following steps:

[0072] S1. Raw material selection: Proportion according to the above-mentioned high-performance low-carbon aluminum alloy composition, and the raw material is an intermediate alloy of pure aluminum and other raw materials;

[0073] S2. Pretreatment: All raw materials are subjected to surface grinding and polishing and ultrasonic vibration pretreatment to remove the influence of oxides and impurities; Use after drying;

[0074] S3. Smelting: add pure aluminum, aluminum-silicon, aluminum-iron, aluminum-manganese, and aluminum-copper intermediate alloys in the raw materials preheated in step S2 into the furnace in sequence, and the temperature in the furnace is rai...

Embodiment 2

[0083] A high-performance low-carbon aluminum alloy, its chemical composition is calculated by mass percentage, Si: 7.29%, Cu: 3.49%, Mg: 0.28%, Fe: 0.38%, Mn: 0.37%, Ti: 0.02%, La: 0.11 %, the rest is aluminum and unavoidable impurities. The preparation method of the alloy is carried out according to the process steps of Example 1.

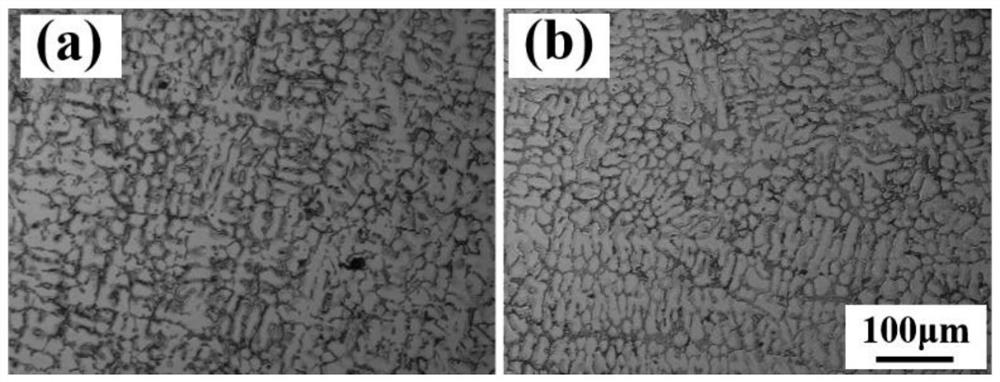

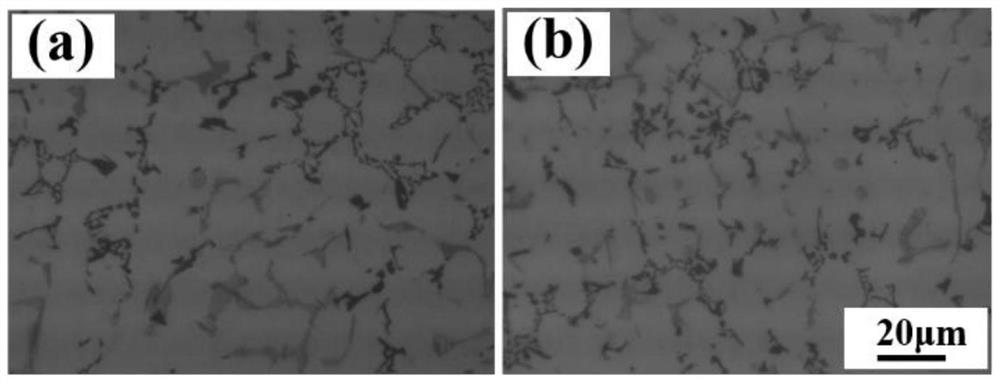

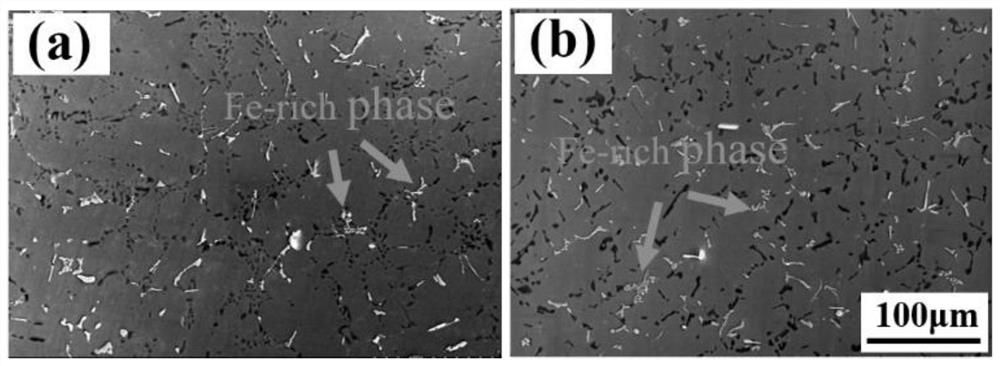

[0084] According to the method of embodiment 1, the obtained aluminum alloy is sampled, processed and tested, and the light microscope photo after the corrosion treatment, the photomicrograph after the eutectic silicon has deteriorated, and the SEM electron microscope image after the heat treatment are respectively as follows figure 1 , figure 2 , image 3 Figure (b) in. The results show that the average secondary dendrite arm spacing in Example 2 is 13.42 μm, the average equivalent diameter of eutectic silicon is 3.63 μm, and the average circularity is 0.47.

[0085] According to the method of Example 1, the mechanical properties of the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com