Completely biodegradable heat shrink film material, completely biodegradable heat shrink film and preparation method

A heat-shrinkable film and biodegradable technology, applied in the field of heat-shrinkable film materials, can solve the problems of polluted environment and difficult degradation of heat-shrinkable film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

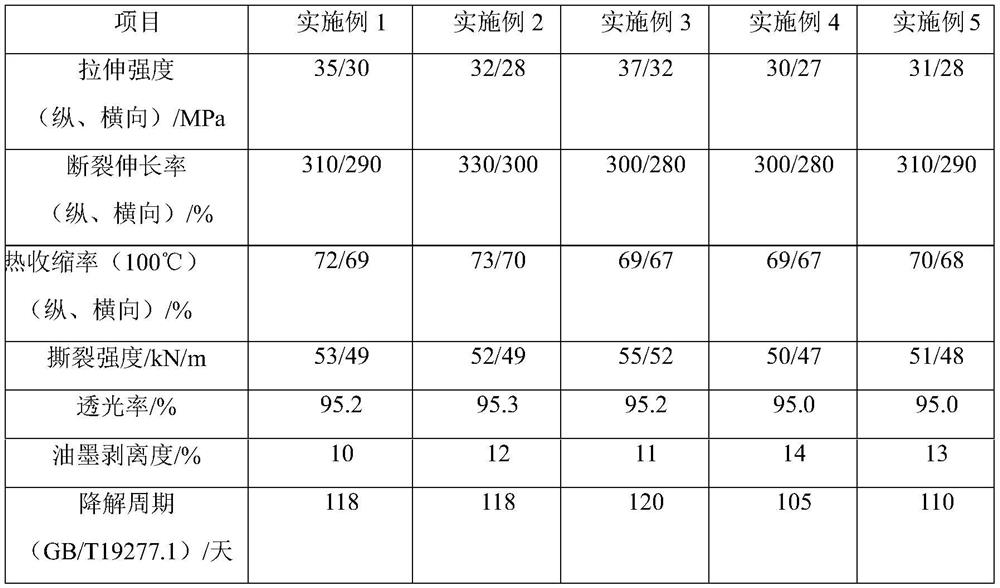

Examples

preparation example Construction

[0032] A preparation method of a fully biodegradable heat-shrinkable film:

[0033] (1) Raw material modification: mix corn pollen polysaccharide, enteromorpha powder, starch, and plasticizer for modification, and the raw material modification temperature is 80-100°C to obtain a modified mixture;

[0034] (2) Mixing: In the modified mixture obtained in step 1), add polylactic acid, polybutylene terephthalate, antioxidant, chain extender, anti-blocking agent, mix uniformly, and the mixing temperature 80-100°C to obtain a blended mixture;

[0035] (3) Granulation and film blowing: the mixed mixture prepared in step 2) is extruded and granulated by a twin-screw granulator, and blown by a film blowing machine. A transparent fully biodegradable heat shrinkable film is obtained.

[0036] Among them, the enteromorpha powder is obtained by drying and crushing the fresh enteromorpha. After the fresh enteromorpha is washed, the water content is 90%-95%, and it is centrifugally dehydra...

Embodiment 1

[0039] Weigh 1 part of corn pollen polysaccharide, 5 parts of Enteromorpha powder, 17 parts of starch, 0.5 part of water, 4.5 parts of glycerin, 1 part of citric acid and mix and modify at 80 ° C; add 10 parts of polylactic acid, polyethylene terephthalate 58.7 parts of butylene diacid, 0.1 part of antioxidant 1010, 0.4 part of antioxidant 168, 0.5 part of BASF ADR4468, 0.3 part of erucamide, mixed evenly, put into twin-screw granulator, granulation temperature 150 ℃, blown film The temperature is 150°C to produce a fully biodegradable heat-shrinkable film.

Embodiment 2

[0041] Weigh 3 parts of corn pollen polysaccharide, 4 parts of Enteromorpha powder, 15 parts of starch, 1 part of polyethylene glycol, 2 parts of acetyl tributyl citrate, and 5 parts of glycerin and mix and modify at 90 ° C; add 5 parts of polylactic acid , 63.1 parts of polybutylene terephthalate, 0.2 parts of 10100.2 parts, 0.2 parts of 168, 1 part of BASF ADR4468, 0.2 parts of erucamide, and 0.4 parts of stearic acid amide were mixed evenly, and put into a twin-screw granulator to make The particle temperature is 140°C, and the film blowing temperature is 140°C, to produce a fully biodegradable heat shrinkable film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com