Pesticide micro-granule for spraying foliage in air, and preparation method and application of pesticide micro-granule

A microparticle and foliar spray technology, which is applied in the field of new pesticide formulations, can solve problems such as loss and pesticide deposition rate of less than 50%, and achieve the effect of overcoming evaporation and drift, optimizing spraying and operating parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

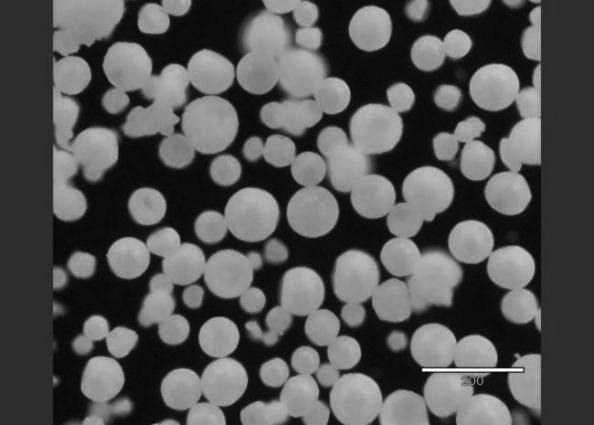

[0052] 0.5% methylamino abamectin benzoate emulsifiable microgranules: fully shear and mix the original drug containing 2.5 g methylamino abamectin benzoate and 10 g alkylphenol polyoxyethylene ether, About 37.5 g of water were slowly added under shear to form a microemulsion. 5g lignosulfonate, 5g acrylic acid-sulfonate copolymer, 15g long-chain polycarboxylate, 10g dodecyl sulfate, 5g sodium carboxymethyl cellulose, 100g urea, 50g potassium dihydrogen phosphate, 10g of soluble starch and 280g of kaolin were accurately weighed and added to a shearing kettle containing about 500g of water for shearing and mixing, and then into a sand mill for sand grinding. When the average particle size reached about 2 microns, it was transferred to the modulation kettle.

[0053] The microemulsion containing methylamino abamectin benzoate prepared above was added to the above preparation kettle under stirring conditions, sheared and mixed for about 10 minutes, and spray-dried and granulated....

Embodiment 2

[0056] 3% trioxystrobin-tebuconazole emulsifiable microgranules: fully shear and mix the original drug containing 5g trichostrobin and 10g tebuconazole, 20g alkylphenol polyoxyethylene ether and 10g N-methylpyrrolidone, evenly, About 55 g of water was slowly added under shear to form a microemulsion. 10g dodecyl sulfate, 5g sodium carboxymethyl cellulose, 100g urea, 50g potassium dihydrogen phosphate, 10g soluble starch, 280g kaolin were respectively accurately weighed and added to a shearing kettle filled with about 500g water, shearing and mixing. , and then into a sand mill for sand grinding, and when the average particle size reaches about 2 microns, spray drying and granulation are performed.

[0057]At the same time as the above spray-drying granulation, the microemulsion containing tristrobin and tebuconazole prepared above was sprayed onto the boiling microparticles in the spray-drying granulator, together with a 5% polyvinyl alcohol aqueous solution. Adjust and contr...

Embodiment 3

[0061] 0.3% dicamba emulsifiable microgranules: the original drug containing 3g dicamba and 30g lignosulfonate, 15g long-chain polycarboxylate, 15g sodium carboxymethyl cellulose, 10g soluble starch, 100g dodecyl Sodium sulfate and 800g of bentonite were respectively accurately weighed and added to a shearing kettle containing about 1000g of water, sheared and mixed, and then entered into a sand mill for sand grinding. When the average particle size reached about 2 microns, they were transferred to the modulation kettle.

[0062] Shear mixing for about 10 minutes and spray drying granulation. Adjust and control the spray drying operation parameters [specifically, refer to the prior art in the field of spray granulation technology, and those of ordinary skill in the art can realize it without paying creative work], control the granulation, the average particle size is 100 microns, and the granulation is 32 mesh (495 microns in turn). micron) and 325 mesh (47 micron) sieve, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com