Oil powder composition for chicken feed as well as preparation method and application of oil powder composition

A technology of composition and chicken feed, which is applied in the molding or processing of animal feed, application, animal feed, etc. It can solve the problems of no more detailed regulations and requirements for oil, limited improvement of poultry feed utilization rate and daily weight gain, etc. , to avoid fatty liver problems, improve digestion utilization and anti-oxidation, and improve feed utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

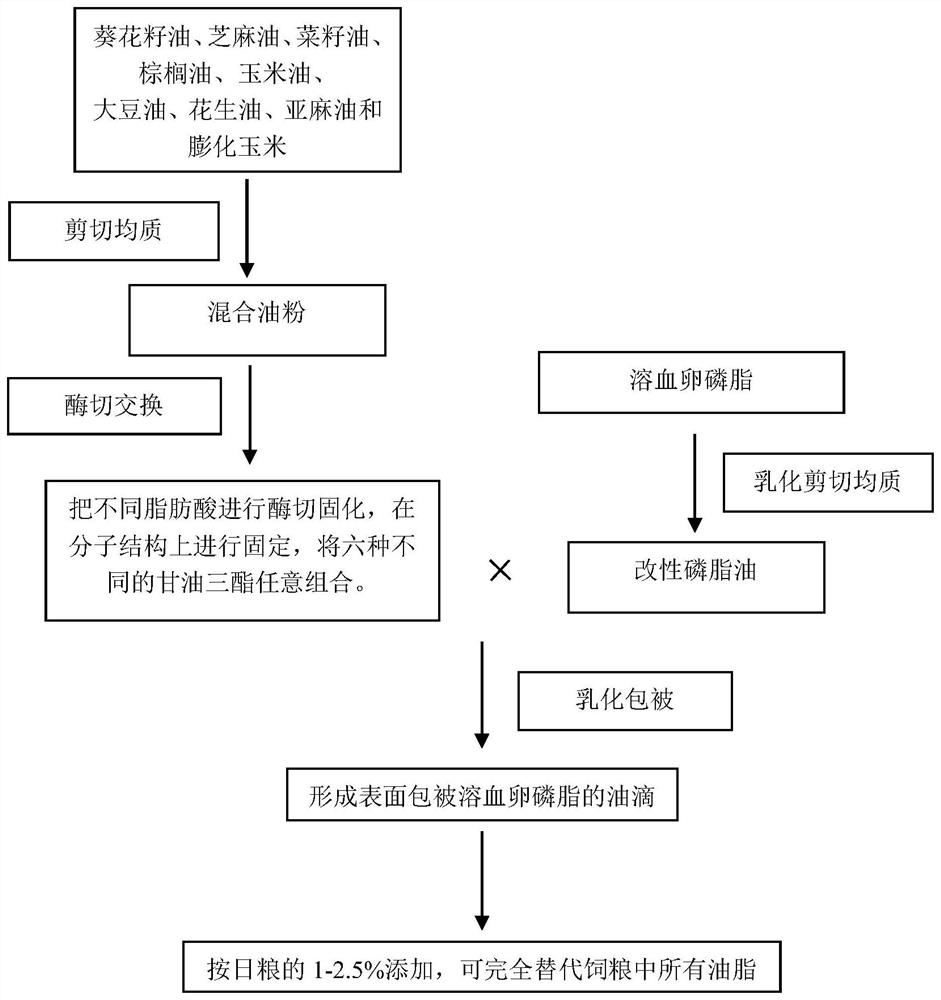

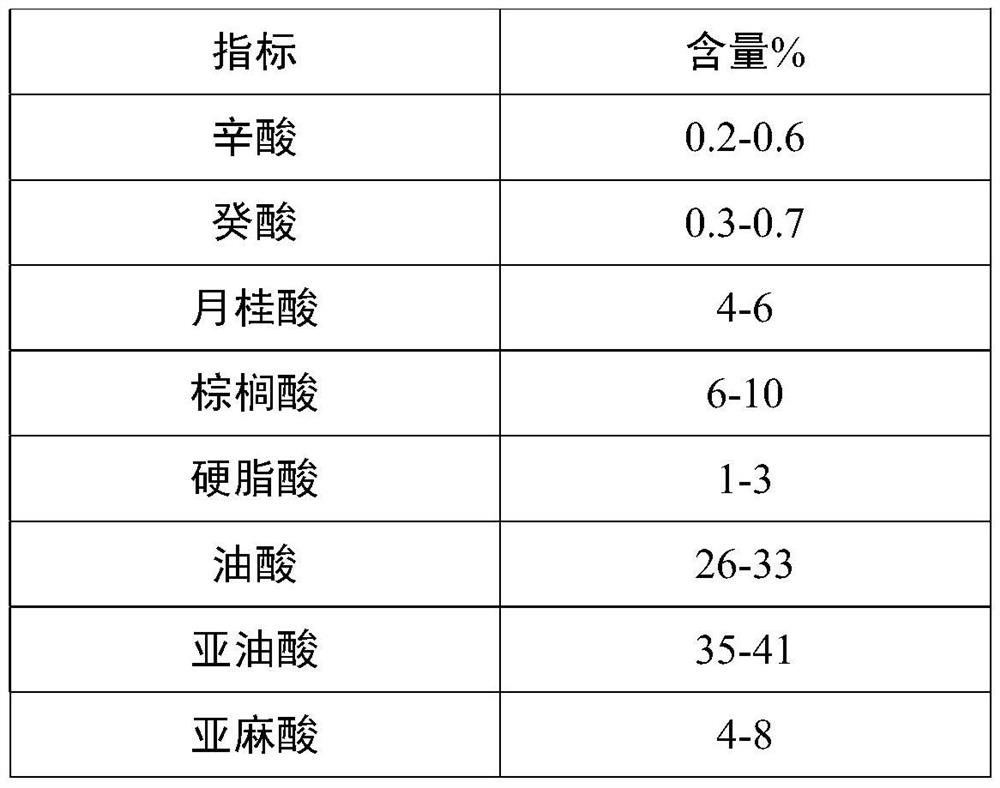

[0034] The invention utilizes technologies such as emulsification, shearing, homogenization, enzymatic hydrolysis, and microcapsule coating to process various oils and fats, and develops traditional single liquid oils into high digestibility and balanced fatty acid, which can improve feed utilization and reduce egg dark spots , and improve the complex powdered oil of egg protein components, such as figure 1 As shown, the detailed preparation method is as follows:

[0035] (1) A mixture of various vegetable oils

[0036] The fat in this embodiment mainly includes mixed oil and puffed corn, and the mass ratio thereof is 5:4.5. After calculating the fatty acid content in various raw material oils, various vegetable oils are mixed in a certain proportion. In parts by weight, the mixed oil is composed of 8 parts of sunflower oil, 7 parts of sesame oil, 15 parts of rapeseed oil, and 10 parts of palm oil. , 40 parts of corn oil, 10 parts of linseed oil, and 10 parts of soybean oil....

Embodiment 2

[0049] 1 Materials and methods

[0050] 1.1 Experimental materials and feeding management

[0051] Select 1,350 Nongda No. 5 parent laying hens with the same physical condition and production performance, and divide them into control group (containing 0.5% soybean oil), treatment group I (containing 1% balanced oil), and treatment group II (containing 1.5% balanced oil) , 450 rats in each group, and 6 repetitions in each group. The feeding period was 5 weeks.

[0052] Here, the dosage of the control group and the treatment group is determined according to the total metabolic energy, and the original feed is conventional chicken feed, which contains ingredients such as corn, soybean meal, stone powder and premix. Since the metabolizable energy of soybean oil is higher than that of balanced oil, adding the same amount of soybean oil and metabolized oil will result in different metabolic energy of the feed, which is difficult to compare. Therefore, more metabolized oil is used ...

Embodiment 3

[0063] 1 Materials and methods

[0064] 1.1 Experimental materials and feeding management

[0065] 324 Hebei Rongde Poultry Breeding Co., Ltd. in good health and similar production performance of 412-day-old "Nongda No. 3" laying hens were selected for the test. They were randomly divided into 2 groups (control group and test group), with 6 replicates in each group and 27 laying hens in each replicate, which were raised in the same environment. The control group was fed a conventional diet containing 1.5% soybean oil. In order to keep the metabolic energy of the two groups of diets consistent, 1.85% balanced oil was used to replace the soybean oil in the conventional diet for the experimental group. The test period is 35 days, and the pre-trial period is 7 days.

[0066] The amount of soybean oil and balanced oil used here is the same as in Example 2. In order to keep the total energy of feed metabolism of the control group and the test group the same, different mass ratios ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com