Cassava feed capable of changing high grains into low grains and preparation method of cassava feed

A cassava and feed technology, applied in animal feed, animal feed, molding or processing of animal feed, etc., can solve problems such as body condition decline of pregnant sows, affect pig growth and development, and large loss of backfat after weaning, so as to improve feed intake Quantity, shorter time to market, good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

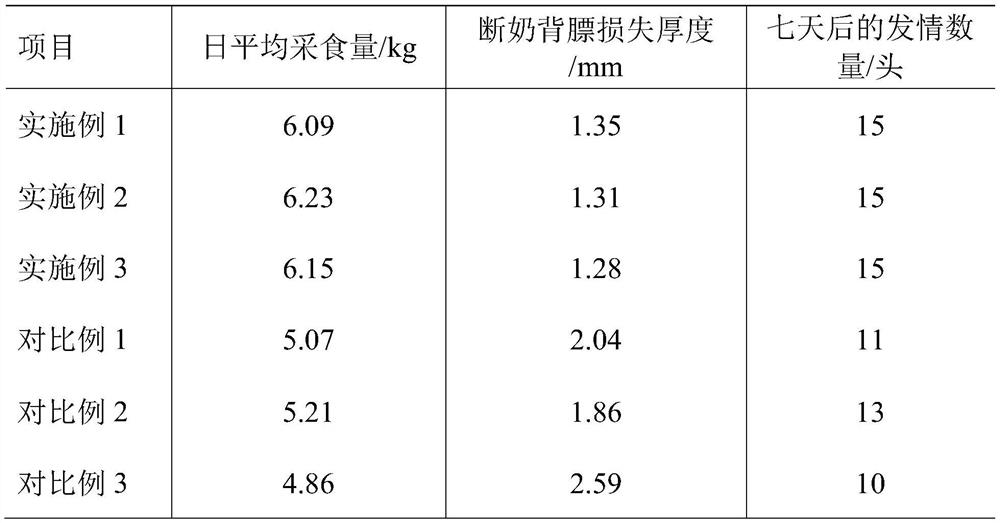

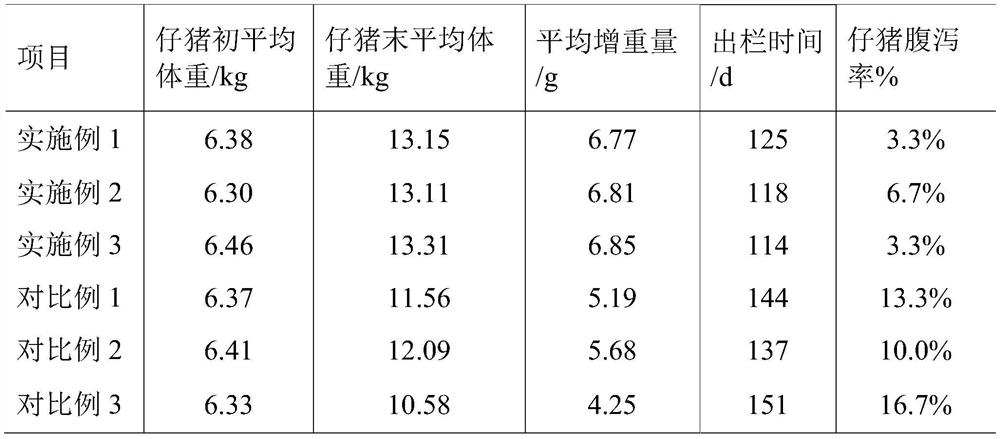

Examples

Embodiment 1

[0029] A kind of preparation method of high-grain to low-grain type cassava feed comprises the following steps:

[0030] Step 1: Peel the cassava, cut into pieces and soak in clean water for 10 minutes, dry at 60°C until the water content is 10%, and crush to 40-50 mesh to obtain cassava flour;

[0031] Step 2: Soak cassava leaves and cassava skins in 0.5% w / w sodium chloride solution for 0.5 hours, then wash them with clean water, dry them in the sun, and crush them to 40-50 meshes to obtain the cassava leaf skin mixture;

[0032] Step 3: Wash the sugarcane tail leaves and ramie leaves with a mass ratio of 1:1, dry, pulverize, add acetic acid aqueous solution with a concentration of 0.15% w / w and mix, and the solid-to-liquid ratio is 1:20g / ml. Under 15MPa, carry out acidification treatment for 15min, add 0.3wt% biological agent and 1wt% sugar solution, wherein, the biological agent is aspergillus niger and plantarum lactobacillus with a mass ratio of 1:2, and the viable count...

Embodiment 2

[0037] A kind of preparation method of high-grain to low-grain type cassava feed comprises the following steps:

[0038] Step 1: Peel the cassava, cut into pieces and soak in clean water for 20 minutes, dry at 65°C until the water content is 13%, and then crush to 40-50 mesh to obtain cassava flour;

[0039] Step 2: Soak cassava leaves and cassava skins in 1% w / w sodium chloride solution for 1 hour, then wash them with clean water, dry them in the sun, and crush them to 40-50 meshes to obtain the cassava leaf skin mixture;

[0040] Step 3: Wash the sugarcane tail leaves and ramie leaves with a mass ratio of 2:5, dry, pulverize, add acetic acid aqueous solution with a concentration of 0.25% w / w and mix, and the solid-to-liquid ratio is 1:30g / ml. Under 10MPa, carry out acidification treatment for 30min, add 0.5wt% biological agent and 3wt% sugar solution, wherein, the biological agent is aspergillus niger and plantarum lactobacillus with a mass ratio of 1:2, and the viable count...

Embodiment 3

[0045] A kind of preparation method of high-grain to low-grain type cassava feed comprises the following steps:

[0046] Step 1: Peel the cassava, cut into pieces, soak in clean water for 15 minutes, dry at 63°C until the moisture content is 12%, and crush to 40-50 mesh to obtain cassava flour;

[0047] Step 2: Soak cassava leaves and cassava skins in 0.8% w / w sodium chloride solution for 0.8 hours, then wash them with clean water, dry them in the sun, and crush them to 40-50 meshes to obtain the cassava leaf skin mixture;

[0048] Step 3: Wash the sugarcane tail leaves and ramie leaves with a mass ratio of 1:3, dry them, crush them, add acetic acid aqueous solution with a concentration of 0.2% w / w and mix them, and the solid-liquid ratio is 1:25g / ml. Under 13MPa, acidify for 20 minutes, add 0.4% biological agent and 2% sugar solution of sugarcane tail leaf and ramie leaf powder quality, wherein, the biological agent is Aspergillus niger and plant milk with a mass ratio of 1:2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com