Phosphorus salt amphiphilic bifunctional organic catalyst as well as preparation method and application thereof

An organic catalyst and amphiphilic technology, which is applied in the field of phosphorus salt amphiphilic bifunctional organic catalyst and its preparation, can solve the problems of multi-component weighing and measurement, increased errors, accuracy and mechanism research, etc. problems, to achieve the effect of precise components, short synthetic routes, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The synthetic route of catalyst CAT1 is as follows:

[0083]

[0084] in, The molecular structure formula is as follows:

[0085]

[0086] The preparation process is as follows:

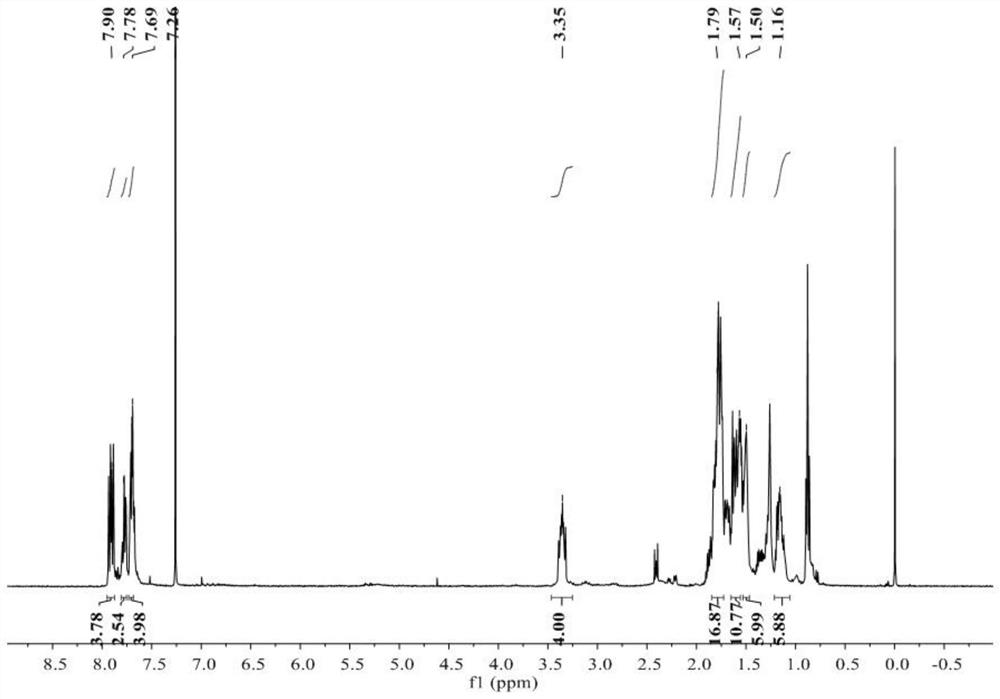

[0087] In a flame-dried Schlenk vessel, diallyldiphenylphosphine bromide (173.6 mg, 0.5 mmol, 1 equiv) and 9-borabicyclo[3.3.1]nonane (9-BBN) (122 mg, 1.0 mmol, 2.0 equiv) was dissolved in 10 mL of chloroform. The reaction mixture was allowed to stir at 80 °C for 12 hours. All volatiles were removed and the resulting white solid was washed 3 times (10 mL) with hexanes to give the desired product in quantitative yield, product 1 H NMR spectrum as figure 1 Shown (400MHz, CDCl 3 , 298K).

Embodiment 2

[0089] The synthesis of catalyst CAT2, synthetic route is as follows:

[0090]

[0091] in, The molecular structure formula is as follows:

[0092]

[0093] The preparation process is as follows:

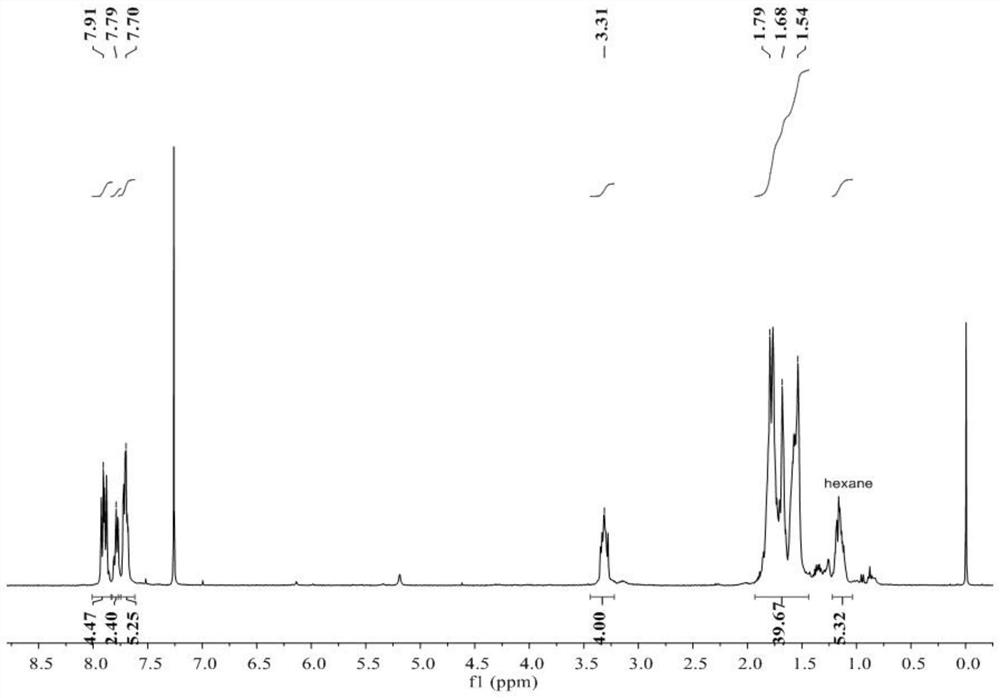

[0094] In a flame-dried Schlenk vessel, diallyldiphenylphosphine iodide (307mg, 0.78mmol, 1 equiv) and 9-borabicyclo[3.3.1]nonane (9-BBN) (190.4mg, 1.56 mmol, 2 equivalents) dissolved in 10mL CHCl 3 middle. The reaction mixture was allowed to stir at 80 °C for 12 hours. All volatiles were removed and the resulting white solid was washed 3 times (10 mL) with hexane to afford the desired product in quantitative yield, product 1 H NMR spectrum as figure 2 Shown (400MHz, CDCl 3 , 298K).

Embodiment 3

[0096] The synthetic route of catalyst CAT4 is as follows:

[0097]

[0098] The preparation process is as follows:

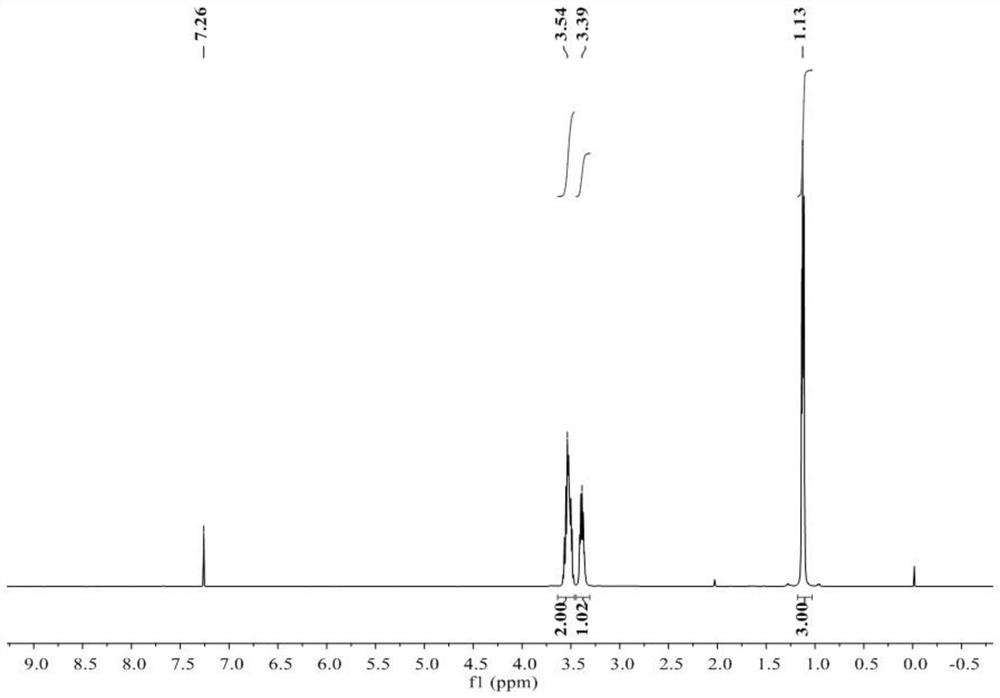

[0099] In a flame-dried Schlenk vessel, dissolve CAT1 (118.3 mg, 0.2 mmol, 1 equiv) and sodium benzoate (115.3 mg, 0.8 mmol, 4 equiv) in 8 ml of CHCl 3 middle. The reaction mixture was allowed to stir at room temperature for 48 hours. The filtrate was collected by filtration under nitrogen to remove all volatiles and the resulting white oil was washed 3 times (10 mL) with hexane to obtain the desired white quantitative product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com