Magnesium hydroxide modified waste brick, preparation method thereof and application of magnesium hydroxide modified waste brick in artificial wetland system

A constructed wetland system and magnesium hydroxide technology are applied in magnesium hydroxide modified waste bricks and their preparation, and the application field in constructed wetland systems can solve the problems affecting the denitrification and phosphorus removal efficiency, the loss of magnesium hydroxide powder, and the inability to directly application and other issues, to achieve the effect of improving the efficiency of nitrogen and phosphorus removal, promoting microbial activity, and promoting resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] One embodiment of the present invention proposes a preparation method of magnesium hydroxide modified waste brick, which is characterized in that it comprises the following steps:

[0041] (1) Broken and sieved construction waste bricks to obtain waste brick particles;

[0042] (2) Air plasma treatment is carried out to the above-mentioned waste brick particles to obtain waste bricks etched by plasma;

[0043] (3) Disperse the waste bricks etched by the above plasma into seawater, first ultrasonic, and dropwise add sodium hydroxide solution, second ultrasonic, wash, and dry to obtain magnesium hydroxide modified waste bricks.

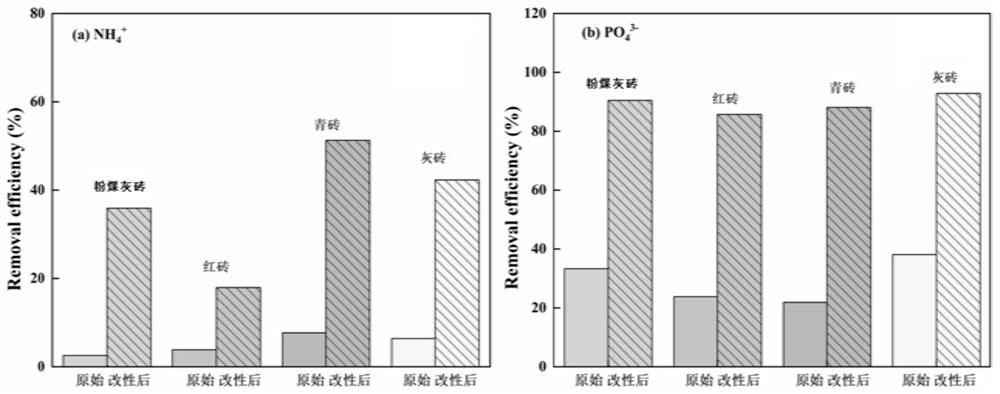

[0044] In an embodiment of the present invention, in step (1), the waste building bricks include at least one of fly ash bricks, red bricks, blue bricks and gray bricks. It should be pointed out that construction waste bricks are waste clay bricks produced during building demolition, reconstruction or construction, including but not limited to f...

Embodiment 1

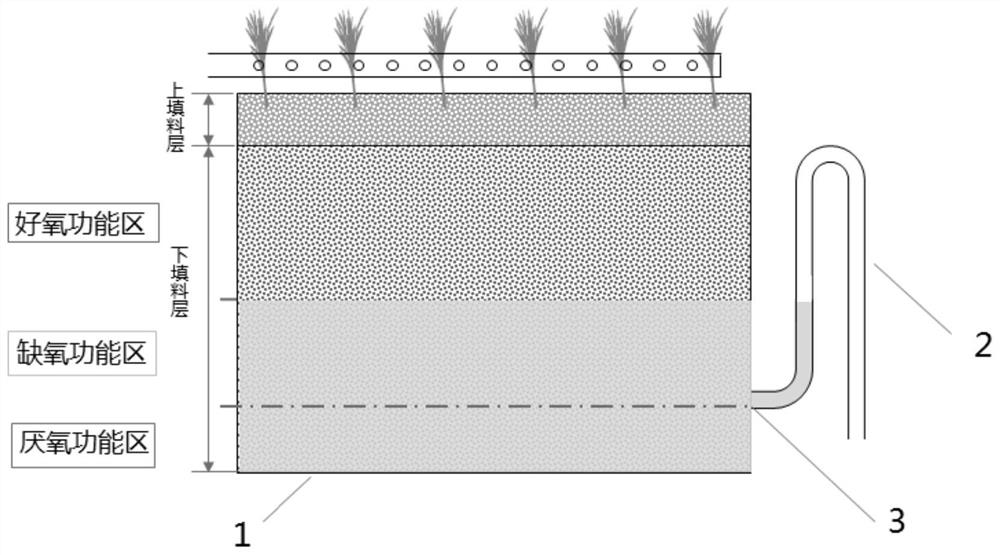

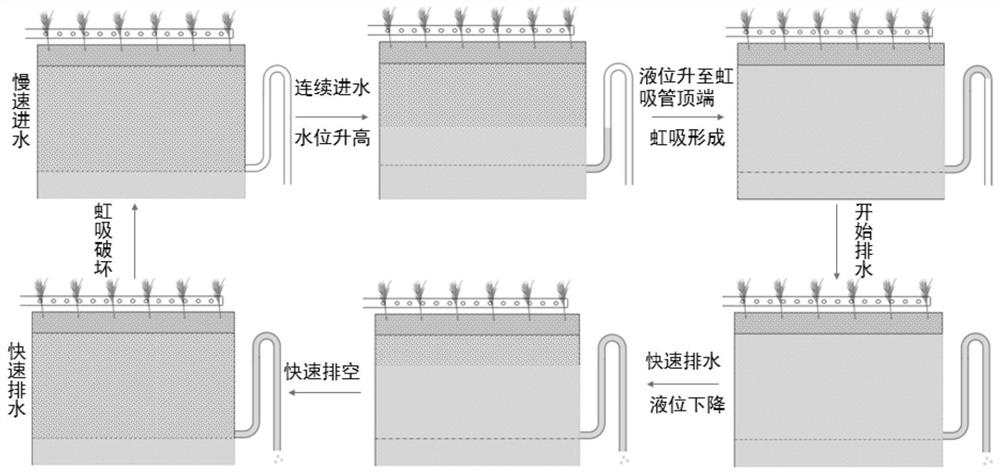

[0078] Example 1 A method of treating sewage by using artificial wetland system

[0079] (1) prepare modified magnesium hydroxide, comprise the steps:

[0080] Crushing and screening of waste bricks: The Hammer Crusher crushes the collected construction waste bricks (blue bricks), and the broken waste bricks are screened separately to obtain waste brick particles with uniform particle size (1-10mm);

[0081] Plasma etching: put the screened waste bricks into the plasma reaction device, set the irradiation power supply to 100w, and the irradiation time to 30min, and use air plasma to etch the surface of the waste bricks to increase the porosity and specific surface area of the material ;

[0082] Ultrasonic-assisted nano-magnesium hydroxide loading: disperse 1g of waste bricks after plasma etching into 50mL of seawater (Mg 2+ concentration of 0.15mol / L), put the waste brick seawater mixed solution in the ultrasonic cell breaker, set the ultrasonic time to 60min, then slow...

Embodiment 2

[0093] Example 2 A method of treating sewage by using artificial wetland system

[0094] Same as Example 1, the difference is that when preparing modified magnesium hydroxide, the waste building bricks are made of fly ash bricks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com