Wall protection material, permeable reactive barrier and preparation method of permeable reactive barrier

A technology of wall material and reaction wall, applied in the field of retaining wall material, permeable reaction wall and preparation thereof, can solve the problems of reducing the permeability coefficient of the wall and soil, easily blocking the wall and the soil of the side wall, etc., so as to improve the permeability of the wall. coefficient, ensure long-term operation, and ensure the effect of physical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The present embodiment provides a wall protection material, which consists of 90 tons of guar gum, 9 tons of sodium carbonate, and 1 ton of cotton wool.

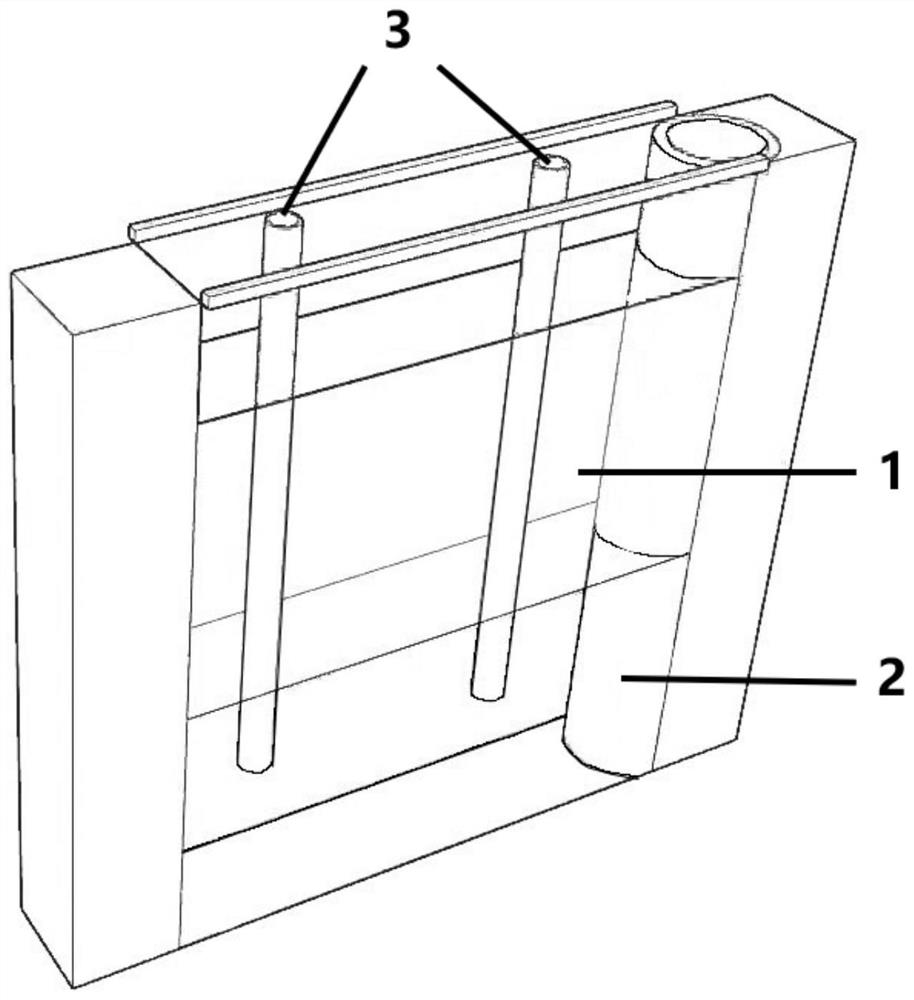

[0080] This embodiment also provides a permeable reactive wall, the raw materials of which include 100 tons of the above-mentioned wall protection material, 90 tons of 100-mesh river sand, 5 tons of 300-mesh zero-valent iron powder, and 5 tons of coated hydrocolloid degrading enzyme.

[0081] Among them, the coated hydrocolloid degrading enzymes include: 9 tons of mannanase, 1 ton of polyvinyl alcohol, and 0.5 tons of polyethylene. The preparation method includes: mixing 9 tons of mannanase and 1 ton of polyvinyl alcohol to prepare mannanase granules with an average particle size of 1.5mm; adding 0.5 tons of polyethylene to 12.5 tons of tetrachlorethylene and heating to 100°C , stirring and dissolving to obtain the coating solution; use a heater to heat the air inside the fluidized bed equipment to 75°C, and then add ...

Embodiment 2

[0087] This embodiment provides a wall protection material, which consists of 80 tons of xanthan gum, 5 tons of sodium hydroxide, and 0.1 tons of azoxystrobin.

[0088] This embodiment also provides a permeable reactive wall, the raw materials of which include 85.1 tons of the above-mentioned wall protection material, 85 tons of 100-mesh river sand, 7 tons of 300-mesh iron-carbon filler, and 10 tons of coated hydrocolloid degrading enzyme.

[0089] Among them, the coated hydrocolloid degrading enzymes include: 8 tons of galactosidase mannanase, 2 tons of attapulgite, and 1 ton of polyurethane DP3070A. The preparation method includes: mixing 8 tons of galactosidase mannanase and 2 tons of attapulgite to prepare galactosidase mannanase particles with an average particle size of 1.2 mm; adding 20 tons of dichloromethane to 1 ton of polyurethane DP3070A In methane, heat to 80°C, stir and dissolve to obtain the coating liquid; use the heater to heat the nitrogen inside the fluidize...

Embodiment 3

[0095] This embodiment provides a wall protection material, which consists of 95 tons of carrageenan, 15 tons of potassium hydroxide, and 2 tons of chlorobromoisocyanuric acid.

[0096] This embodiment also provides a osmotic reaction wall, the raw materials of which include 112 tons of the above-mentioned wall protection material, 80 tons of 90-mesh river sand, 10 tons of zeolite and 10 tons of coated hydrocolloid degrading enzyme.

[0097] Among them, the coated hydrocolloid degrading enzymes include: 9 tons of galactase and 2 tons of sodium lignosulfonate, 0.3 tons of epoxy resin CYD-014U, the preparation method is: 9 tons of galactase and 2 tons of lignin Sodium sulfonate was mixed to prepare galactase granules, with an average particle size of 3 mm; 0.3 tons of epoxy resin CYD-014U was added to 9 tons of acetone, heated to 120 ° C, stirred and dissolved to obtain a coating solution; the fluidized The air inside the bed equipment is heated to 90°C, and then 11 tons of mann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com