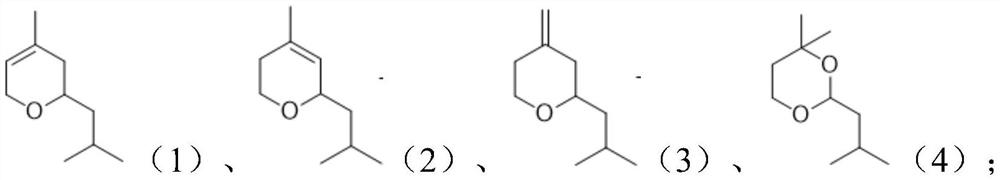

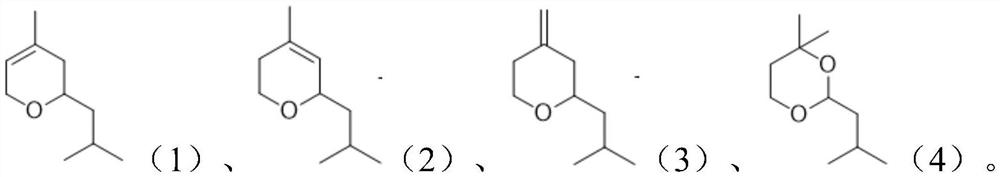

Resource utilization method of waste containing dehydration by-products and dioxane by-products in lily pyran production process

A lily-of-the-valley pyran and production process technology are applied in the field of resource utilization containing dehydration by-products and dioxane by-product wastes, and can solve the problems of less utilization of dioxane by-product wastes and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of praseodymia-alumina supported tungsten oxide catalyst Al 2 o 3 -Pr 6 o 11 -WO 3 :

[0051] 1) 100 g of praseodymium chloride and 120 g of aluminum chloride were prepared into an aqueous solution with a concentration of 25 wt %, stirred at 33° C. for 30 min, then slowly added dropwise to the solution with ammonia water at a concentration of 15 wt % to adjust the pH to 10, and continued to stir for 30 min, Al 2 o 3 -Pr 6 o 11 The composite carrier is rolled into a powder with a particle size of 20-50um for later use.

[0052] 2) Prepare 50 g of sodium tungstate (dihydrate) into an aqueous solution with a concentration of 13 wt%, and add Al 2 o 3 -Pr 6 o 11 Composite carrier 200g, stirred at 30°C for 30min, transferred to an oven, dried at 120°C to constant weight, weighed 50g of dry matter, added 3g of molding agent methylcellulose, and added 14g of water in several times as lubricant, Stir evenly, after granulation by granulator (particle size...

Embodiment 2

[0056] Preparation of praseodymia-alumina supported molybdenum oxide catalyst Al 2 o 3 -Pr 6 o 11 -MoO 3 :

[0057] 1) Prepare 100 g of praseodymium chloride and 100 g of aluminum chloride into an aqueous solution with a concentration of 10 wt %, stir at 20 ° C for 60 min, then slowly add 5 wt % ammonia water to the solution to adjust the pH to 9, continue stirring for 10 min, and filter 1. After washing to neutrality, calcined at 500°C for 12 hours in an air atmosphere to obtain Al 2 o 3 -Pr 6 o 11 The composite carrier is rolled into a powder with a particle size of 20-50um for later use.

[0058] 2) Ammonium molybdate 50g was prepared into an aqueous solution with a concentration of 5wt%, and added Al 2 o 3 -Pr 6 o 11 Composite carrier 350g, stirred at 20°C for 60min, transferred to an oven, dried at 90°C to constant weight, weighed 50g of dry matter, added 4.5g of polyacrylamide as a forming agent, and added 17.5g of water in several times as a lubricant, Stir...

Embodiment 3

[0062] Preparation of praseodymia-alumina supported molybdenum oxide and tungsten Al oxide 2 o 3 -Pr 6 o 11 -WO 3 -MoO 2 :

[0063] 1) Prepare 100 g of praseodymium chloride and 150 g of aluminum chloride into an aqueous solution with a concentration of 40 wt %, stir at 40 ° C for 10 min, then slowly add 25 wt % ammonia water to the solution to adjust the pH to 11, continue stirring for 30 min, and filter 1. After washing to neutrality, calcined at 800°C for 3 hours in an air atmosphere to obtain Al 2 o 3 -Pr 6 o 11 The composite carrier is rolled into a powder with a particle size of 20-50um for later use.

[0064] 2) Each 25g of sodium tungstate (dihydrate) and ammonium molybdate was used to prepare an aqueous solution with a total concentration of 20wt%, adding Al 2 o 3 -Pr 6 o 11 Carrier 100g, stirred at 40°C for 10min, then transferred to an oven, dried to constant weight at 150°C, took 50g of dry matter, added 1g of molding agent methyl cellulose, added 10g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com