Low-shrinkage long-carbon-chain polyamide elastomer foamed bead as well as preparation method and application thereof

A technology of carbon chain polyamide and foamed beads, which is applied in the production of bulk chemicals, etc., can solve the problems of low shrinkage rate of foamed beads, easy shrinkage of foamed beads, and low crystallization temperature, and achieve the size and volume Uniformity, low shrinkage, and improved melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

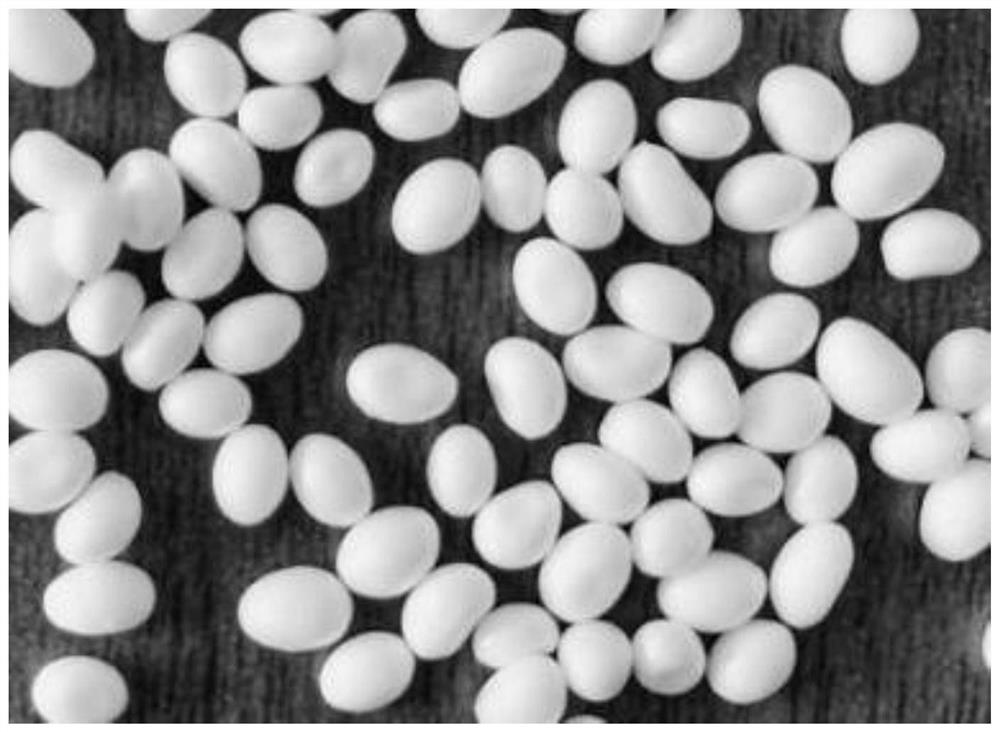

[0060] In the present embodiment, the specific steps for preparing long carbon chain polyamide elastomer (LCPAE) foamed beads (A1) are as follows:

[0061]Preparation of long carbon chain polyamide elastomer: Add 207kg of dodecyl dibasic acid and 102kg of decanediamine in a 1500L high-pressure reactor, replace the air in the reactor with nitrogen flow for 10min, and heat to 250°C under nitrogen flow atmosphere , and close the nitrogen flow after 1h, keep the reactor in an airtight state, and the mixed materials continue to react in the reactor for 1h. Then vacuumize to reduce the pressure in the reactor to -98kPa, dehydrate and keep the vacuum for 30 minutes, then stop the vacuum, then use nitrogen to return to a state slightly greater than atmospheric pressure, and then add 300.0kg PTMEG2000 and catalyst tetrabutoxyl to the reactor Titanium 0.05kg, 1098 antioxidant 1kg. Heating to 250°C under nitrogen atmosphere and stirring for 30 minutes, then evacuating to -98kPa, reactin...

Embodiment 2

[0067] In the present embodiment, the specific steps of preparing long carbon chain polyamide elastomer (LCPAE) foamed beads (B1) are as follows:

[0068] Preparation of long carbon chain polyamide elastomer: Add 232.0kg tetradecanedioic acid and 120.0kg dodecyl diamine into a 1500L high-pressure reactor, replace the air in the reactor with nitrogen flow for 10min, and Heating to 250°C, and closing the nitrogen flow after 1 hour, keeping the reactor in a sealed state, and continuing to react the mixed material in the reactor for 2 hours. Then vacuumize to reduce the pressure in the reactor to -98kPa, dehydrate and keep the vacuum for 30 minutes, then stop vacuuming, then use nitrogen to return to a state slightly greater than atmospheric pressure, and then add 600kg of PTMEG 3000 and catalyst tetrabutoxyl to the reactor Titanium 0.05kg, 1098 antioxidant 1kg. Heating to 255°C under nitrogen atmosphere and stirring for 30 minutes, then evacuating to -98kPa, reacting at constant...

Embodiment 3

[0074] In the present embodiment, the specific steps of preparing long carbon chain polyamide elastomer (LCPAE) foamed beads (A2) are as follows:

[0075] Add 1 kg of the ellipsoidal long carbon chain polyamide elastomer foamed particles obtained in Example 1 and 2 kg of water into a 30L high-pressure foaming kettle, and start stirring at a speed of 10 r / min. The foaming conditions are set with reference to Table 1. Then inject high-pressure CO through the plunger pump 2 , while heating, when the temperature in the kettle reaches 132°C and the pressure reaches 25MPa, stop pressurizing and heating. Heat preservation and pressure for 60 minutes to make the foamed particles of the long carbon chain polyamide elastomer reach saturation, and obtain a polymer-supercritical fluid homogeneous system.

[0076] Open the discharge valve at the bottom of the autoclave, and foam the polymer-supercritical fluid homogeneous system at a rate of 30 MPa / min to obtain LCPAE foamed beads (A2). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com