Mutagenesis and screening method for improving yield of microalgae oil

A microalgae oil and high oil technology, applied in biochemical equipment and methods, microbial determination/inspection, microorganisms, etc., can solve the problem of lack of high oil production verification, inability to obtain mutant algal strains, lack of analysis of photosynthetic performance of algal strains, etc. problems to avoid omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment provides a method for cultivating microalgae liquid to the logarithmic phase, comprising the following steps:

[0060] (1) All the BG11 medium and Erlenmeyer flasks were sterilized at 121°C for 20 minutes;

[0061] (2) Inoculate 100mL of Scenedesmus liquid into a 500mL conical flask containing 120mL of BG11 medium, seal the mouth of the bottle with a sterile film, and place it in a constant temperature light incubator at 25°C with a light intensity of 80μmol·( m 2 s) -1 , continuous culture under the condition of light cycle 12L / 12D, in order to prevent cell attachment from affecting growth during the culture process, shake the flask 3-4 times a day and change the position of the Erlenmeyer flask randomly;

[0062] (3) To be cultured to the logarithmic phase, the cell concentration is 10 6 About one / mL, take 0.1mL of algae liquid and put it in a sterilized plastic cover for mutagenesis;

Embodiment 2

[0064] This embodiment provides a method for utilizing ARTP to mutate microalgae, comprising the steps of:

[0065] (1) Get 0.1 mL of the algae liquid in the logarithmic phase provided in Example 1, apply it on the sterilized plastic cover, and move the plastic cover to the stage below the plasma with tweezers;

[0066] (2) Air is used as the working gas of the plasma, the power of the mutagenometer is adjusted to 120W, the radiation distance between the plastic cover and the outlet of the mutagenometer is adjusted to 2mm, the gas flow rate is 5SLM, and the mutagenesis treatment time is set for mutagenesis For each experimental condition, three parallel experiments were performed.

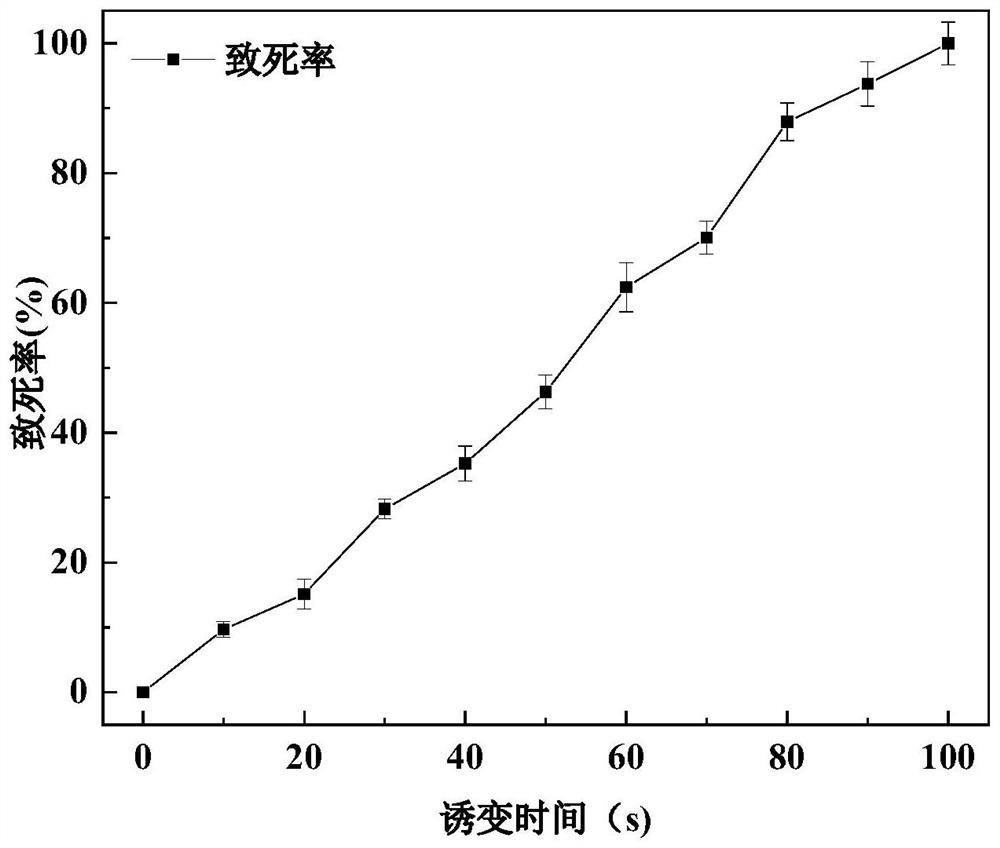

[0067] Performance analysis: exploring the optimal mutagenesis time

[0068] The optimal mutagenesis time of the method for the ARTP mutagenesis microalga provided by embodiment 2 is explored with reference to the following method:

[0069] (1) Set the mutagenesis treatment time as 0s, 10s, 20s, ...

Embodiment 3

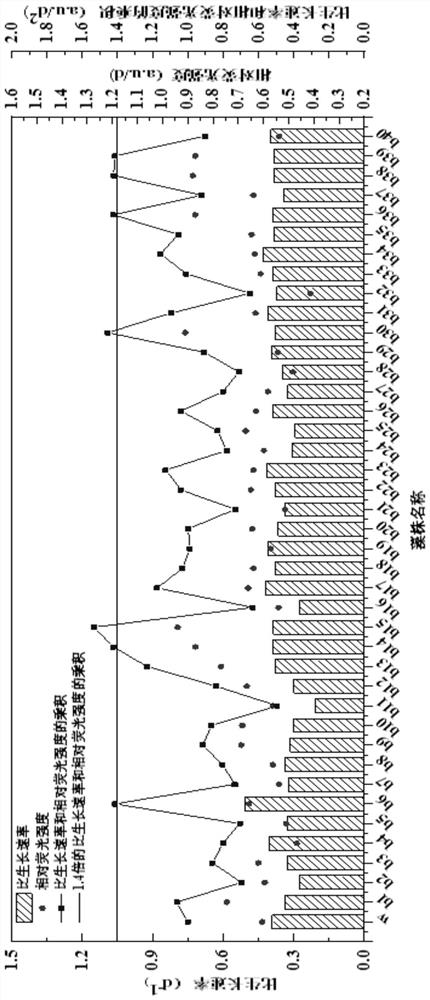

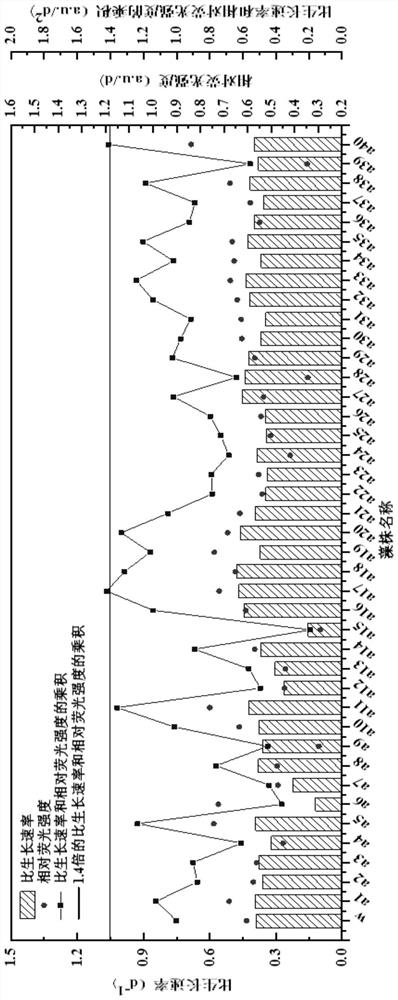

[0078] This embodiment provides a method for screening algae strains using a medium containing malonate after ARTP mutagenesis, comprising the following steps:

[0079] (1) Utilize the ARTP mutagenesis method provided in Example 2 to carry out mutagenesis treatment to the Scenedesmus algae fluid in the logarithmic phase of Example 1, and the mutagenesis time is 90s;

[0080] (2) Transfer the mutagenized algae solution to the protection solution (BG-11 medium containing 5% glycerol), suspend and stabilize it in the light incubator for 3 hours;

[0081] (3) Take 1 mL of the suspended algae solution and add it to 9 mL of the mixed solution (BG-11 medium containing 5% glycerol) for dilution;

[0082] (4) Add 200 μL of diluted algae liquid to 90 mL of solid plate containing BG-11 medium and spread it evenly with a sterilized triangular coating rod, wherein malonic acid is added to BG-11 medium, the concentration If it is 100mg / L, cover it immediately and put it upside down into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com