Method for preparing chitosan oligosaccharide, chitosanase as well as gene, enzyme preparation and application of chitosanase

A chitosanase enzyme and chitosanase technology, applied in the field of hydrolase, can solve the problems of product destruction, high equipment requirements, difficult application, etc., and achieve good temperature stability, good enzymatic hydrolysis effect, and high enzymatic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Enzyme Discovery and Sequence Analysis

[0032] For finding chitosanase gene, researchers of the present invention from Methanothrix ( Methanothrixsp.) (According to literature reports, this bacterium belongs to archaea and mostly lives in extreme ecological environments. Researchers speculate that the potential chitosanase contained in this bacterium may have a relatively special activity) and discovered a segment of the encoded protein The potential chitosanase protein containing 1109 amino acids, whose amino acid sequence is shown in SEQ ID NO.1, is named MS-1109. According to the protein sequence comparison analysis, the highest sequence similarity between the protein and the reported glycoside hydrolase is only 34%, indicating that it is a new type of chitosanase.

Embodiment 2

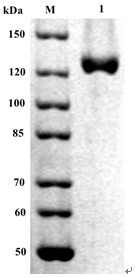

[0033] Embodiment 2 Expression vector construction, expression and enzyme protein purification of enzyme gene

[0034] The codon-optimized nucleotide sequence of the MS-1109 enzyme is shown in SEQ ID NO.2. After the sequence is artificially synthesized, it is connected to the pET-21a(+) vector using seamless junction technology to obtain the recombinant vector pET-21a- MS-1109. The recombinant vector was transformed into Escherichia coli DH5α competent cells by heat shock method. Spread the heat-shock treated cells onto the LB medium plate containing ampicillin, culture overnight at 37°C, select positive clones that can grow on the plate for colony PCR verification, purify the PCR products and send them for sequencing. The correct clones verified by sequencing are the strains containing the successfully recombined plasmid vectors. The strain was picked and cultured in LB liquid medium at 37°C for 20 h. The plasmid was extracted using a plasmid extraction kit. The extracted p...

Embodiment 3

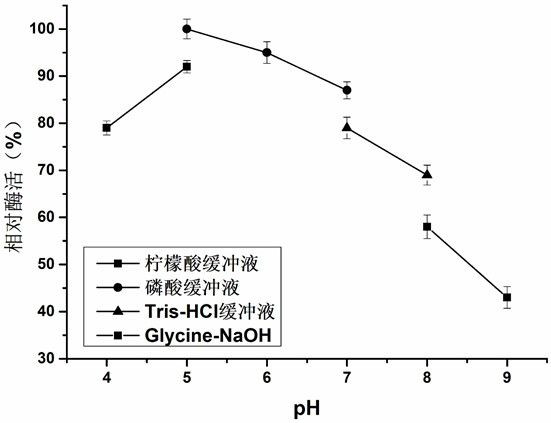

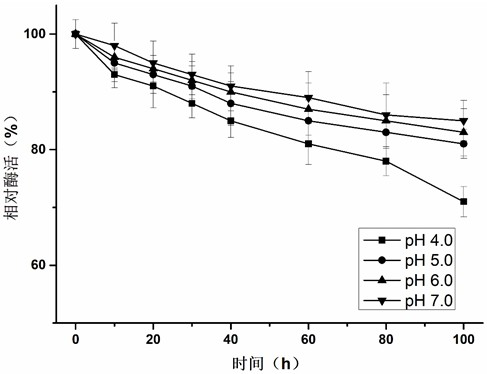

[0036] Example 3 Research on enzymatic properties

[0037] Enzyme activity assay method: use DNS chromogenic method to detect chitosan enzyme activity, mix 20 μL enzyme solution with 80 μL chitosan (2%) solution, and add 200 μL buffer solution to form a 300 μL reaction system. Put the reaction system in a water bath at 50°C for 10 minutes. After the reaction, quickly boil the water bath for 10 minutes to inactivate the enzyme, then add 300 μL of DNS color development solution, and boil the mixture for 5 minutes. After the color development is completed, cool it down rapidly. And add 1 mL of deionized water, use a microplate reader to detect its absorbance at 540 nm, and calculate the enzyme activity according to the absorbance.

[0038] Determination of optimal reaction pH: Mix 20 μL of enzyme solution with 80 μL of chitosan (2%) solution, add 200 μL of different system buffers with pH 4.0-9.0 to adjust the pH of the system, and place the reaction system in a 50°C water bath ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com