Method for preparing metal bismuth by adopting parallel diaphragm electrodeposition module

An electrodeposition, parallel technology, applied in diaphragms, electrolysis components, electrolysis processes, etc., can solve the problems of iron leaching, high processing cost, and strong volatility of electrolytic solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

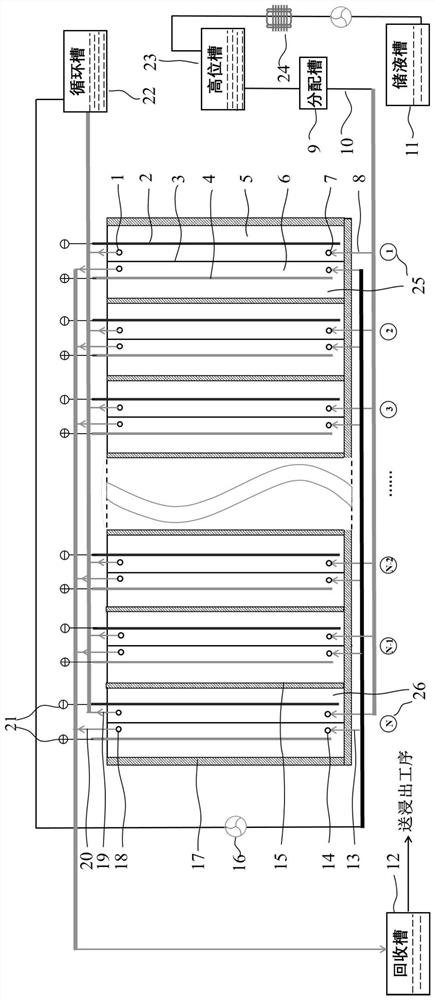

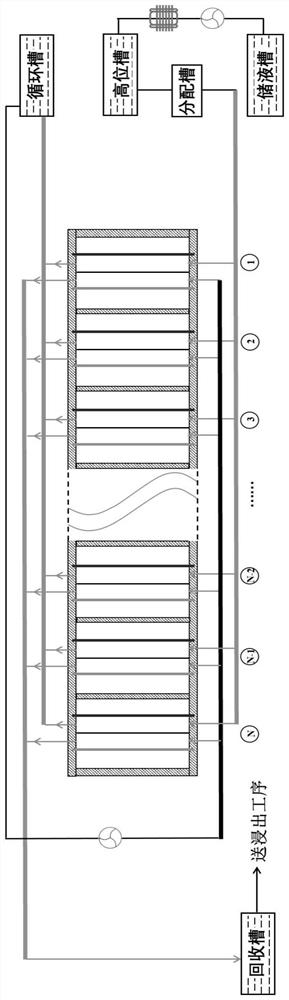

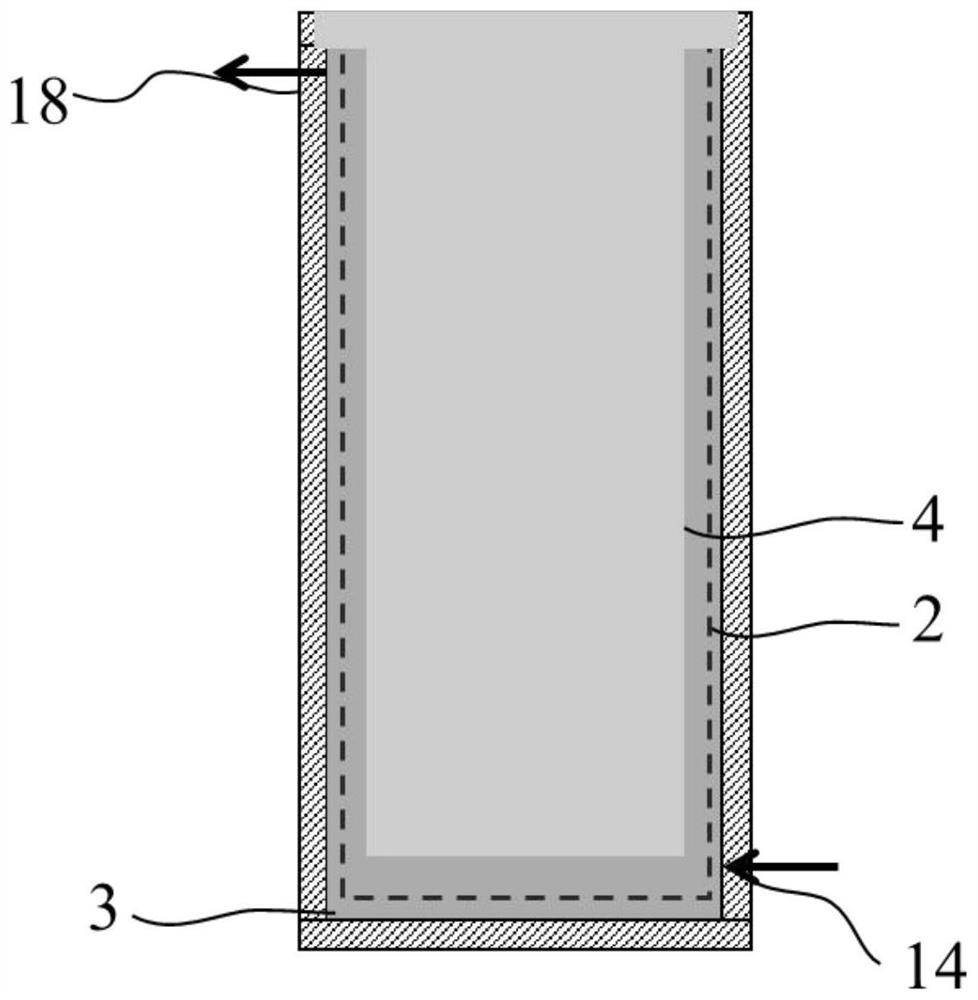

[0042] Utilize bismuth methanesulfonate, ferrous methanesulfonate, and methanesulfonic acid to prepare methanesulfonic acid system electrolysis solution, the concentration of bismuth ions in the electrolysis solution is 60g / L, and the concentration of free methanesulfonic acid is 70g / L, the concentration of ferrous ions is 5g / L. Add the methanesulfonic acid system electrodeposition liquid into the liquid storage tank of the parallel diaphragm electrodeposition module, and transport it to the The cathode chamber of each unit tank of the diaphragm electrodeposition film group. The parallel diaphragm electrodeposition module uses a stainless steel plate as the cathode plate, a graphite plate as the anode plate, and the anion diaphragm as the HeAEMGrion7171 (C) anion membrane. Under the action of an electric field, the bismuth ions in the feed liquid in the cathode chamber of each unit cell generate metal bismuth at the cathode and deposit on the cathode plate; the methanesulfon...

Embodiment 2

[0047] Utilize bismuth methanesulfonate, ferrous methanesulfonate, and methanesulfonic acid to prepare methanesulfonic acid system electrolysis solution, the concentration of bismuth ions in the electrolysis solution is 80g / L, and the concentration of free methanesulfonic acid is 120g / L, the concentration of ferrous ions is 25g / L. Add the methanesulfonic acid system electrodeposition liquid into the liquid storage tank of the parallel diaphragm electrodeposition module, and transport it to the The cathode chamber of each unit tank of the diaphragm electrodeposition film group. The parallel diaphragm electrodeposition module uses a stainless steel plate as the cathode plate, a ruthenium-coated titanium plate as the anode plate, and an anion diaphragm as the IONSEP-HC-A anion membrane. Under the action of an electric field, the bismuth ions in the feed liquid in the cathode chamber of each unit cell generate metal bismuth at the cathode and deposit on the cathode plate; the me...

Embodiment 3

[0052] Utilize bismuth methanesulfonate, ferrous methanesulfonate, and methanesulfonic acid to prepare methanesulfonic acid system electrolysis solution, the concentration of bismuth ions in the electrolysis solution is 100g / L, and the concentration of free methanesulfonic acid is 160g / L, the concentration of ferrous ions is 40g / L. Add the methanesulfonic acid system electrodeposition liquid into the liquid storage tank of the parallel diaphragm electrodeposition module, and transport it to the The cathode chamber of each unit tank of the diaphragm electrodeposition film group. The parallel diaphragm electrodeposition module uses a titanium plate as the cathode plate, a graphite plate as the anode plate, and an anion diaphragm as the IONSEP-HC-A anion membrane. Under the action of an electric field, the bismuth ions in the feed liquid in the cathode chamber of each unit cell generate metal bismuth at the cathode and deposit on the cathode plate; the methanesulfonate anion in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com