Nano material as well as preparation method and application thereof

A nanomaterial and nanosheet technology, applied in the field of sodium ion batteries, can solve the problems of less active sites for sodium storage, large volume effect, and limited development, and achieve excellent electrochemical performance, simple production process, and easy industrial scale-up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

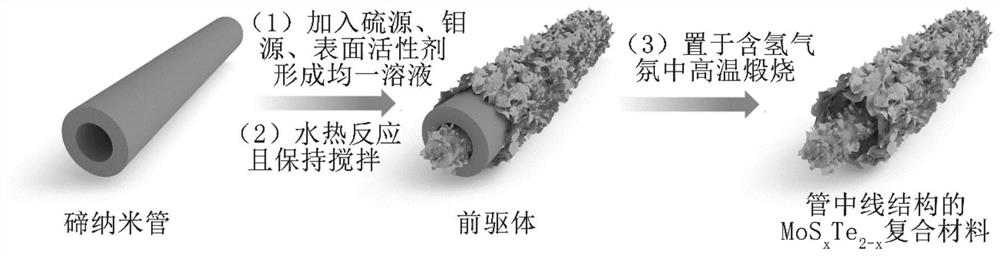

[0072] 1. Pretreatment of raw materials;

[0073] 1.44g of tellurium dioxide, 1.8g of polyvinylpyrrolidone (K30) and 150ml of ethylene glycol solution were placed in a 250mL round bottom flask, stirred at 130°C for 30min, and then heated to 200°C at a constant rate of 5°C / min. 0.9 g of sodium hydroxide was quickly added thereto, continued stirring at 200 °C for 2 h, and then centrifuged and dried to obtain tellurium nanotubes.

[0074] 2. Preparation of precursors;

[0075] Dissolve 50 mg of tellurium nanotubes prepared above, 100 mg of D-glucose, 150 mg of sodium molybdate and 300 mg of thiourea in 30 ml of deionized water solvent. After half an hour of ultrasonication, the resulting mixed solution is placed in a reaction kettle and transferred to React in an oil bath at 180°C for 10 hours. After the reaction, the product is centrifuged and dried to obtain a black solid powder precursor;

[0076] 3. Calcination process;

Embodiment 2

[0092] Preparation of carbon-free film MoS 1.5 Te 0.5 The preparation process of the tube centerline structure nanocomposite is the same as that of Example 1, the only difference being that D-glucose is not added during the preparation of the precursor in Example 1.

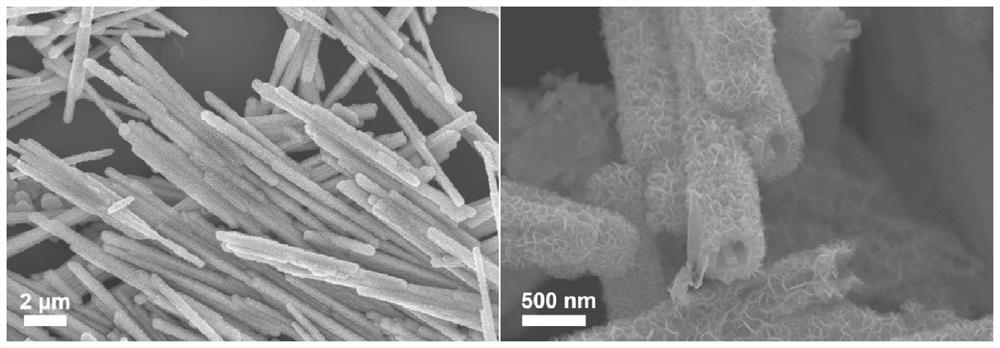

[0093] The precursor prepared in this embodiment is carried out SEM test, the result is as follows Figure 10 As shown, because no surfactant was added, the surface of the Te nanotubes could not grow nanosheets uniformly, and a large number of small balls agglomerated by the nanosheets alone fell on the surface of the precursor.

Embodiment 3

[0095] Preparation of carbon-free film MoS x Te 2-x (where x=0, namely MoTe 2 ) tube midline structure nanocomposite material, the preparation process is the same as in Example 1, the only difference being that in the calcination process in Example 1, high-purity hydrogen is used as the reaction atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com