Solid electrode and preparation method and application thereof

A technology of solid electrodes and solid electrolytes, applied to solid electrodes and their preparation, applications in solid-state batteries, internal construction of solid electrodes for effective ion transmission and their preparation, can solve the problem of low battery capacity, poor ion conductivity, etc. problems, to achieve the effect of improving ion conduction, high specific capacity, and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Another aspect of the embodiments of the present invention provides a method for preparing the aforementioned solid electrode, which includes:

[0054] Provide a uniform mixed reaction system comprising active material particles, conductive additives, solid electrolyte precursor solution, binder and dispersant, wherein the solid electrolyte precursor solution includes an ionic liquid monomer having at least one reactive active group , a mixture of a polymer monomer having at least one reactive active group, an initiator and a lithium salt;

[0055] Applying the homogeneously mixed reaction system on the current collector, and performing heating or light treatment, so that the ionic liquid monomer and polymer monomer in the homogeneously mixed reaction system undergo in-situ polymerization reaction on the surface of the active material particles , so as to coat the surface of the active material particles to form a polyionic liquid-based solid electrolyte; and,

[0056]...

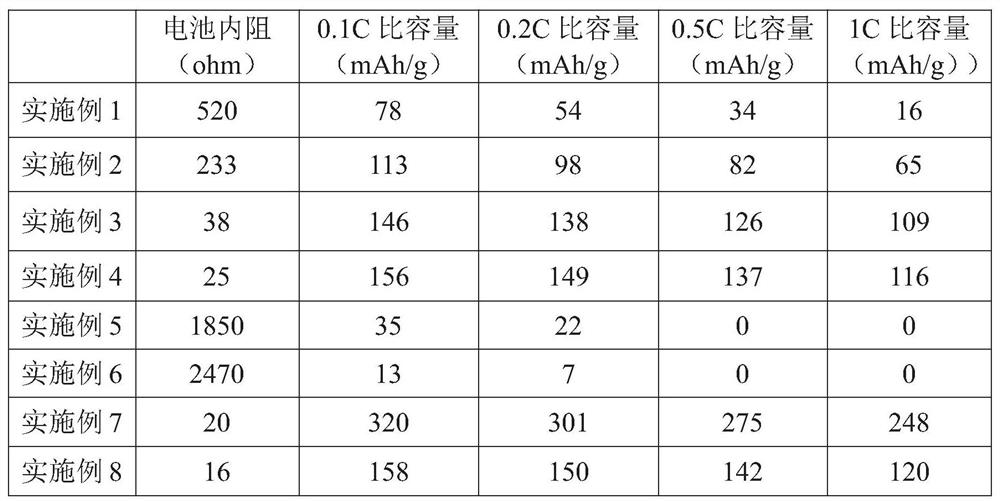

Embodiment 1

[0082] The composition of the solid electrolyte precursor solution: monomer A: vinylimidazole bistrifluoromethanesulfonimide salt (50wt%), monomer B: acrylate monomer (20wt%), lithium salt: bistrifluoromethanesulfonyl Lithium imide (30 wt%), thermal initiator: azobisisobutyronitrile (1% of the total mass of monomer A and monomer B).

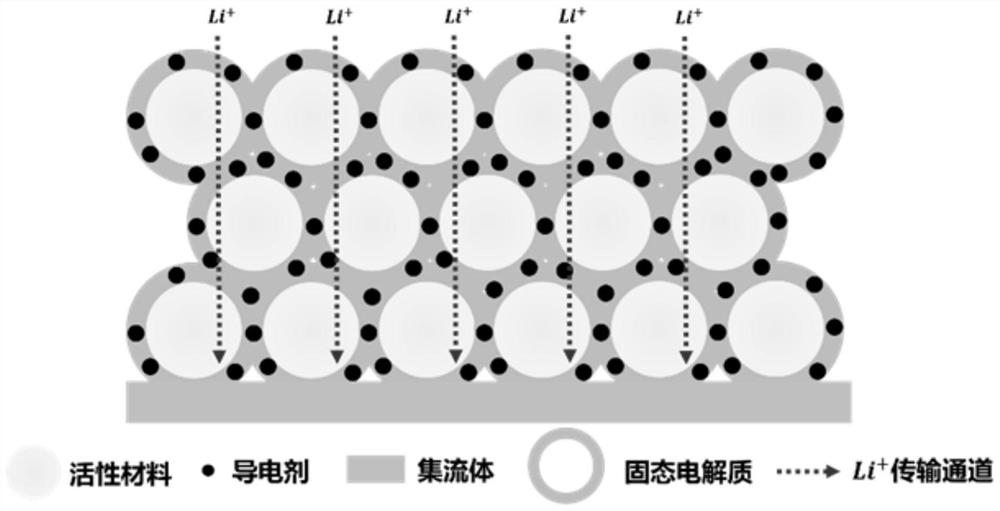

[0083] Preparation of solid electrode: uniformly disperse lithium iron phosphate, conductive agent-conductive carbon black, binder PVDF, and solid electrolyte precursor solution in NMP at a mass ratio of 70:10:10:10, and scrape the dispersion Coated on the surface of aluminum foil with a coating thickness of 200 μm, heated in vacuum at 50°C for 24 hours to polymerize the monomers in the solid electrolyte precursor and remove the solvent NMP at the same time to obtain a solid lithium iron phosphate electrode with a porosity of 3%. The average solid electrolyte contained The molecular weight is about 200,000. The schematic diagram of the internal ...

Embodiment 2

[0085] Solid electrolyte precursor solution composition: monomer A: allyl pyrrole-containing ionic liquid monomer (50wt%), monomer B: acrylate monomer (20wt%), lithium salt: bistrifluoromethanesulfonimide Lithium (30 wt%), thermal initiator: azobisisobutyronitrile (0.5% of the total mass of monomer A and monomer B).

[0086] Preparation of solid electrode: uniformly disperse lithium iron phosphate, conductive agent-conductive carbon black, binder PVDF, and solid electrolyte precursor solution in NMP with a mass ratio of 85:5:0:10, and scrape the dispersion Coated on the surface of aluminum foil with a coating thickness of 200 μm, heated in vacuum at 80°C for 4 hours to polymerize the monomer in the solid electrolyte precursor and remove the solvent NMP at the same time to obtain a solid lithium iron phosphate electrode with a porosity of 5%. The solid electrolyte contained in the average The molecular weight is about 100,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com