Zinc vanadate electro-catalytic material as well as preparation method and application thereof

An electrocatalytic material, the technology of zinc vanadate, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems such as the general shape of zinc vanadate, and achieve the effect of uniform and continuous shape, easy operation and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

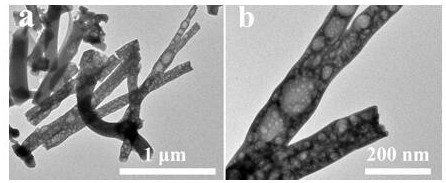

[0051] A preparation method of zinc vanadate electrocatalytic material, comprising steps as follows:

[0052](1) Dissolve 0.45 g of zinc nitrate hexahydrate, 0.12 g of ammonium metavanadate and 1 g of citric acid in 14 mL of deionized water, then add 1.5 mL of hydrochloric acid with a mass concentration of 37 wt%, and stir for 180 min to obtain the precursor body solution;

[0053] (2) Weigh 1.2 g of polyvinylpyrrolidone (PVP) and dissolve it in 15 mL of absolute ethanol, stir well; then add 3 mL of the precursor solution prepared in step (1) into it to obtain the precursor sol; The sol was electrospun at a pressure of 20 kV, a relative humidity of 20%, and room temperature. The spinning receiving distance was 20 cm and the advancing speed was 1 mL / h to obtain precursor fibers.

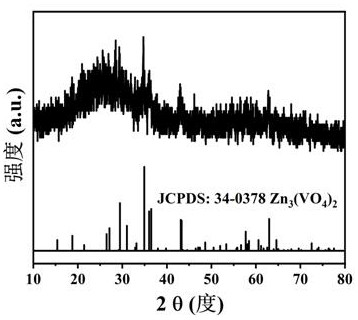

[0054] (3) The precursor fiber prepared in step (2) was dried at 40 °C for 12 h, then placed in a tube furnace, and the temperature was raised to 450 °C at a heating rate of 1 °C / min, at 450 °C The ...

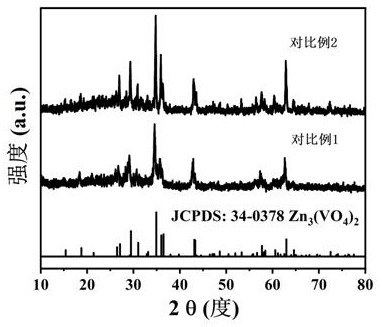

Embodiment 2

[0058] A preparation method of zinc vanadate electrocatalytic material, comprising steps as follows:

[0059] (1) Dissolve 0.45 g of zinc nitrate hexahydrate, 0.12 g of ammonium metavanadate and 1 g of citric acid in 14 mL of deionized water, then add 1.5 mL of nitric acid with a mass concentration of 66 wt%, and stir for 120 min to obtain the precursor body solution;

[0060] (2) Weigh 0.8 g of polyvinylpyrrolidone (PVP) and dissolve it in 10 mL of absolute ethanol, stir well; then add 2 mL of the precursor solution prepared in step (1) into it to obtain the precursor sol; The sol was electrospun at a pressure of 25 kV, a relative humidity of 30%, and room temperature. The spinning receiving distance was 15 cm and the advancing speed was 1.2 mL / h to obtain precursor fibers.

[0061] (3) The precursor fiber prepared in step (2) was dried at 40 °C for 16 h, then placed in a tube furnace, and the temperature was raised to 450 °C at a heating rate of 2 °C / min, at 450 °C The ele...

Embodiment 3

[0063] A preparation method of zinc vanadate electrocatalytic material, comprising steps as follows:

[0064] (1) Dissolve 0.5 g of zinc nitrate hexahydrate, 0.13 g of ammonium metavanadate and 1.12 g of citric acid in 16 mL of deionized water, then add 2 mL of 99 wt% acetic acid dropwise, and stir for 150 min to obtain the precursor body solution;

[0065] (2) Weigh 0.9 g of polyvinylpyrrolidone (PVP) and dissolve it in 12 mL of absolute ethanol, stir well; then add 2 mL of the precursor solution prepared in step (1) into it to obtain the precursor sol; The sol was electrospun at a pressure of 20 kV, a relative humidity of 25%, and room temperature. The spinning receiving distance was 25 cm and the advancing speed was 1 mL / h to obtain precursor fibers.

[0066] (3) The precursor fiber prepared in step (2) was dried at 60 °C for 12 h, then placed in a tube furnace, and the temperature was raised to 450 °C at a heating rate of 2 °C / min, at 450 °C The electrocatalytic material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com