Production process of high-strength aluminum alloy applied to bicycle frame

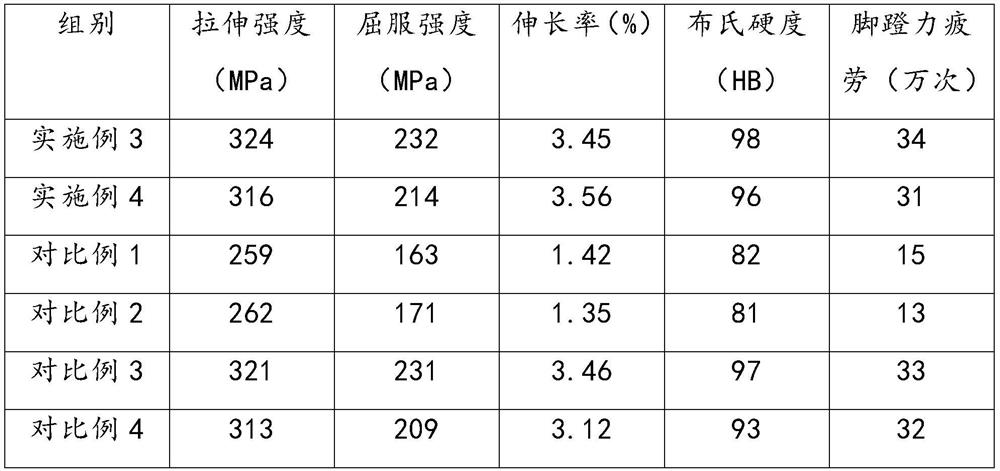

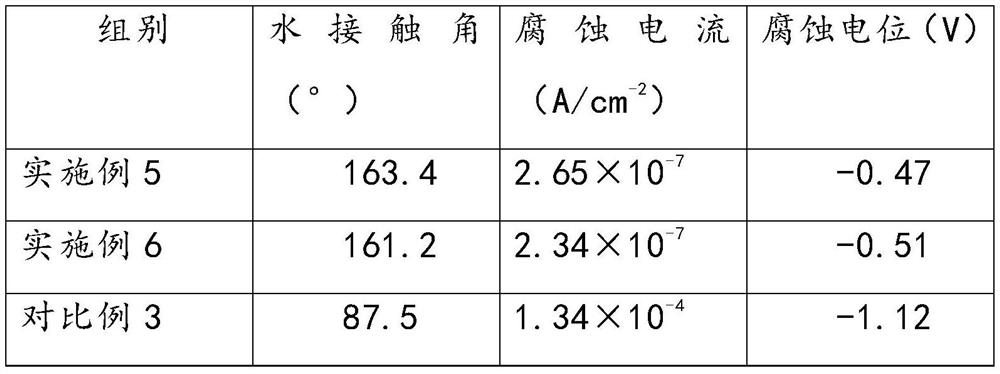

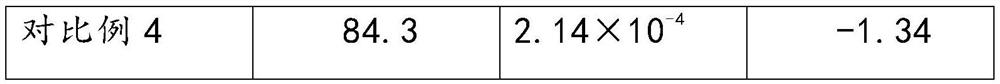

A production process, aluminum alloy technology, applied in the direction of metal material coating process, manufacturing tools, furnaces, etc., can solve the problems of environmental pollution, fatigue resistance and insufficient strength, and increase the nucleation rate, elongation and fatigue resistance. The effect of enhanced performance and increased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The ceramic composite material is prepared by the following steps:

[0031] In the first step, 2g TiB 2 Nanoparticles and 2g CeB 6 Nanoparticles were immersed in 45mL of acetone, filtered, dried, placed in a muffle furnace for oxidation, naturally cooled to room temperature, washed with deionized water, and dried to obtain modified TiB 2 Nanoparticles and Modified CeB 6 Nanoparticles;

[0032] In the second step, after mixing 1.4mL triphenylsilanol and 25mL ethanol aqueous solution evenly, a uniform solution is obtained;

[0033] The third step, the modified TiB 2 Nanoparticles and Modified CeB 6 Nanoparticles are dispersed in a homogeneous solution, stirred and reacted for 1 hour, filtered, washed and dried to obtain a ceramic composite material.

Embodiment 2

[0035] The ceramic composite material is prepared by the following steps:

[0036] In the first step, 2.5g TiB 2 Nanoparticles and 2.4g CeB 6 Nanoparticles were immersed in 50mL acetone, filtered, dried, placed in a muffle furnace for oxidation, cooled to room temperature naturally, washed with deionized water, and dried to obtain modified TiB 2 Nanoparticles and Modified CeB 6 Nanoparticles;

[0037]In the second step, after mixing 2mL triphenylsilanol and 30mL ethanol aqueous solution evenly, a uniform solution is obtained;

[0038] The third step, the modified TiB 2 Nanoparticles and Modified CeB 6 Nanoparticles are dispersed in a homogeneous solution, stirred and reacted for 2 hours, filtered, washed and dried to obtain a ceramic composite material.

Embodiment 3

[0040] A high-strength aluminum alloy production process applied to bicycle frames, comprising the following steps:

[0041] S1. Heat 90 kg of electrolytic aluminum ingot to 720°C to obtain electrolytic aluminum liquid, transfer it to a smelting furnace, add 1 kg of metal Mg, 1 kg of crystalline silicon Si, 0.8 kg of metal Cu, and 0.5 kg of metal Mn, heat to melt and stir evenly Obtain alloy melt;

[0042] S2. The temperature of the alloy melt is controlled in the range of 730° C., and the ceramic composite material prepared in Example 1 with an alloy melt mass of 1.5% is added into the alloy melt, and stirred and mixed evenly;

[0043] S3. Control the temperature to 720°C, blow the aluminum alloy refining agent into the bottom of the furnace evenly with nitrogen through the steel pipe, stir and refine for 10 minutes, remove scum, and let it stand for 1 hour;

[0044] S4, out of the furnace and pouring, to obtain the billet of the cast rod, which is formed by hot extrusion, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com