Method for coating precious metal thermocouple wire with high-temperature-resistant coating

A thermocouple wire, precious metal technology, applied in metal material coating process, coating, thermometers with directly sensitive electrical/magnetic components, etc., can solve thermoelectric signal offset, large workload, oxidation volatilization, etc problems, to achieve the effect of ensuring temperature measurement accuracy, increasing service life, and preventing volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

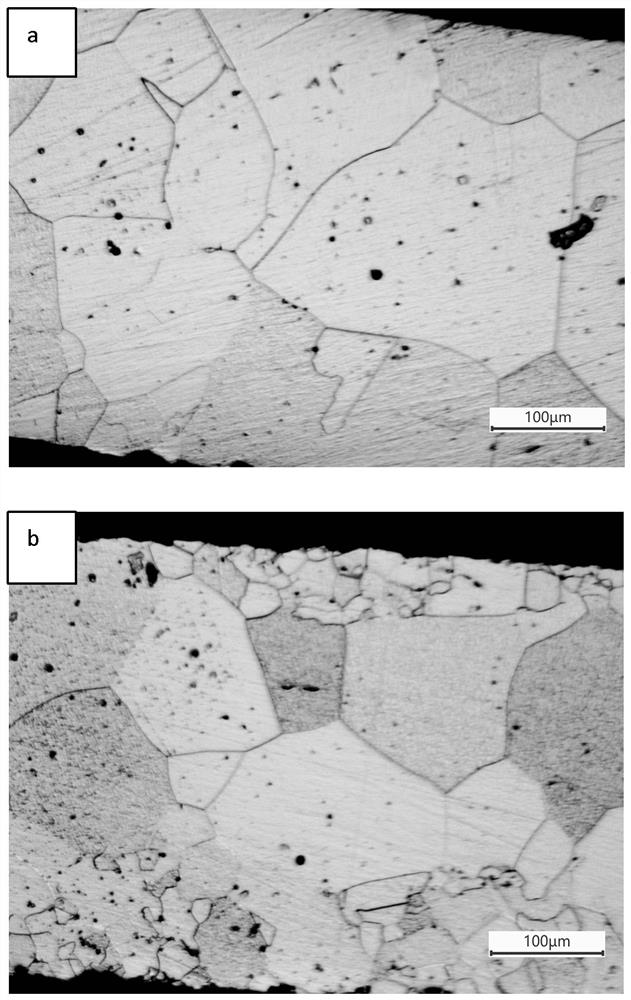

[0034] Put the platinum-rhodium 10-platinum thermocouple wire with a diameter of 0.5mm into 10%wt NaOH solution and boil for 20min, then place it in a hydrochloric acid solution with a concentration of 35%wt and boil for 20min, take it out and wash it several times with distilled water, Until the acid and alkali are cleaned. Place the cleaned silk in a blast drying oven and dry at 85°C for 15 minutes to completely dry the silk. Put the clean and dry wire into the sandblasting machine, use 60-mesh corundum sand, and the sandblasting pressure is 2.5kgf, to blast the surface of the wire to make the surface of the wire evenly roughened, and then use a fan to remove the surface of the wire Attached sand particles, to avoid the attached sand particles affecting the bond strength of the coating. The roughened wire was subjected to plasma spraying treatment, and the platinum-rhodium 10 wire and the platinum wire were respectively clamped on a tooling fixture with an automatic rotatio...

Embodiment 2

[0039] Put the platinum-rhodium 10-platinum thermocouple wire with a diameter of 0.9mm into 10%wt NaOH solution and boil for 20min, then place it in a hydrochloric acid solution with a concentration of 35%wt and boil for 20min, take it out and wash it several times with distilled water, Until the acid and alkali are cleaned. Place the cleaned silk in a blast drying oven and dry at 85°C for 15 minutes to completely dry the silk. Put the clean and dry wire into the sandblasting machine, use 60-mesh corundum sand, and the sandblasting pressure is 3kgf, to blast the surface of the wire to make the surface of the wire evenly roughened, and then use a fan to blow off the surface of the wire Attached sand particles, to avoid the attached sand particles affecting the bond strength of the coating. The roughened wire was subjected to plasma spraying treatment, and the platinum-rhodium 10 wire and the platinum wire were respectively clamped on a fixture with automatic rotation function,...

Embodiment 3

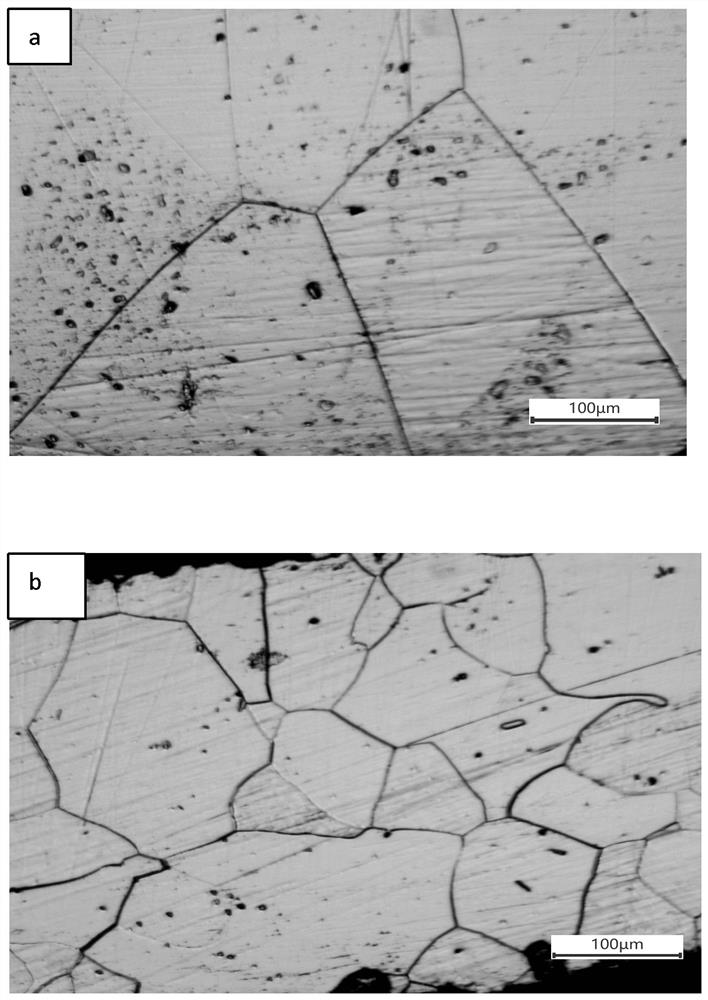

[0044] Put the iridium-rhodium 40-iridium thermocouple wire with a diameter of 0.9mm into 20%wt NaOH solution and boil for 20min, then place it in a hydrochloric acid solution with a concentration of 40%wt and boil for 20min, take it out and wash it several times with distilled water, Until the acid and alkali are cleaned. Place the cleaned silk in a blast drying oven and dry at 85°C for 15 minutes to completely dry the silk. Put the clean and dry wire into the sandblasting machine, use 60-mesh corundum sand, and the sandblasting pressure is 3kgf, to blast the surface of the wire to make the surface of the wire evenly roughened, and then use a fan to blow off the surface of the wire Attached sand particles, to avoid the attached sand particles affecting the bond strength of the coating. The roughened wire was subjected to plasma spraying treatment, and the iridium-rhodium 40 wire and the iridium wire were respectively clamped on a fixture with automatic rotation function, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com