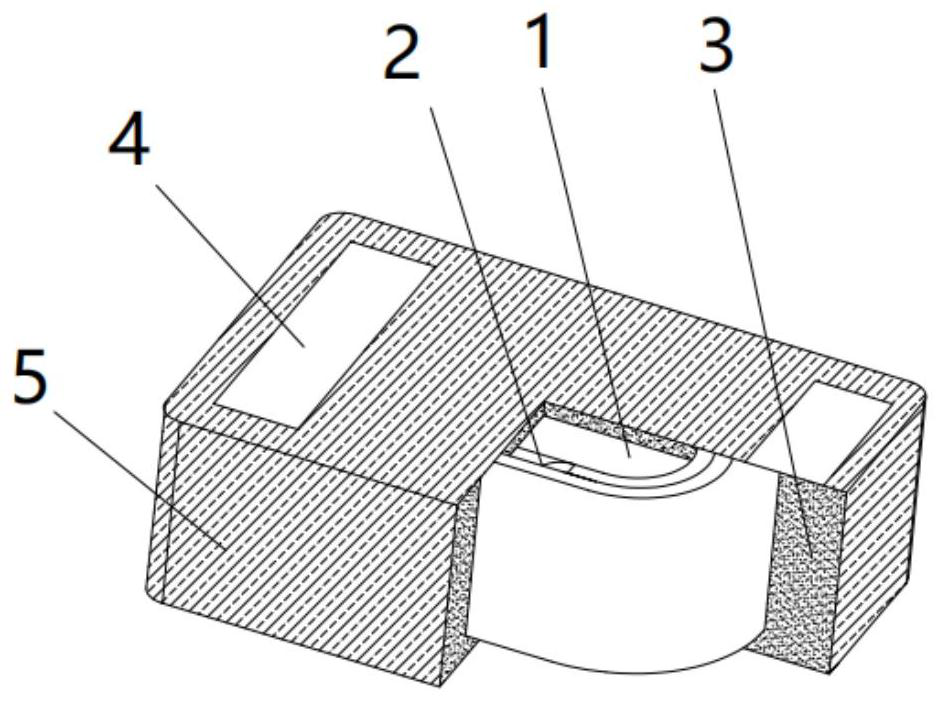

Surface-mounted power inductor and preparation method thereof

A power inductor and chip technology, which is applied in the field of chip power inductors and their preparation, can solve the problems of difficulty in increasing inductance, large coil size, and difficulty in reducing the size of finished inductor products, so as to improve the inductance value, coil size, etc. The effect of reducing the number of turns and reducing the number of coil turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

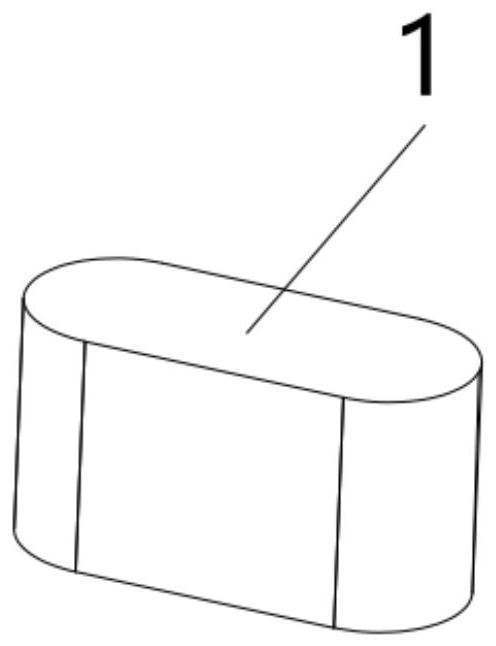

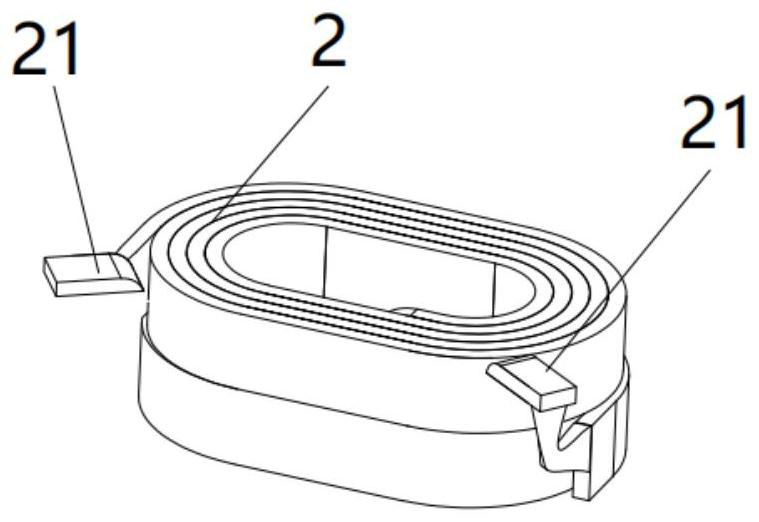

Embodiment 1

[0058] In this embodiment, the soft magnetic alloy center column material is Fe-Si-B-P-Cu amorphous soft magnetic alloy block material, and the soft magnetic alloy composite powder is a composite powder mixed with Fe-Ni soft magnetic alloy powder and iron powder. The agent is epoxy resin, the lubricant used is zinc stearate, and the composite powder is mixed with binder, lubricant and acetone and screened to obtain the target soft magnetic composite powder. The preparation method of the chip power inductor in this embodiment Specifically include the following steps:

[0059] S1. Prefabricated soft magnetic alloy center column: Weigh a certain amount of Fe-Si-B-P-Cu master alloy according to the mass ratio and place it in a vacuum melting furnace for complete melting, pour the soft magnetic alloy liquid into the center column mold, and cool it rapidly Obtain the soft magnetic alloy center column green body, remove the green body and process it to obtain a center column green bo...

Embodiment 2

[0091] In this embodiment, the dimensions of the SMD power inductor are the same as in Embodiment 1, only the number of turns of the coil is reduced to 5.5 turns, and the soft magnetic alloy composite powder is selected from Fe-Si-B-Nb-Cu nanocrystalline soft magnetic alloy The composite powder mixed with powder and iron powder, and the rest of the inductance structure parameters, raw materials, preparation technology and process parameters are the same as those in Example 1, see Example 1 for details. After obtaining the SMD power inductor sample, the average inductance Ls of the sample under the condition of 1V / 1MHz was measured by an impedance analyzer to be 1.032μH, the average saturation current Isat was 4.8A, and the average DC resistance Rdc was 28.2mΩ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com