Sucrose-free fermented milk as well as preparation method and application thereof

A fermented milk, sucrose-free technology, applied in the field of fermented milk, can solve problems such as the inability to achieve long-term shelf life system stability, the inability to fully dissolve and disperse raw materials, gelatinization, and the inability to achieve industrialization, so as to solve the problem of water separation, taste and flavor Excellent, strengthen the effect of texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the yacon powder used is as follows: the yacon fruit is selected, cleaned and peeled, cut into 2mm thin slices with a stainless steel knife, the enzyme is inactivated in a boiling water bath to protect the color for 5 minutes, taken out and drained for freeze-drying, after drying, it is pulverized by a pulverizer, passed After 100 mesh sieves, natural food raw materials are obtained.

[0060] The protein content of the whey protein powder used is 75%. The protein content of the hydrolyzed whey protein powder used is 75%.

[0061] The degree of esterification of the low-ester pectin used was 38%, and the degree of esterification of the high-ester pectin was 65%, purchased from CP Kelco.

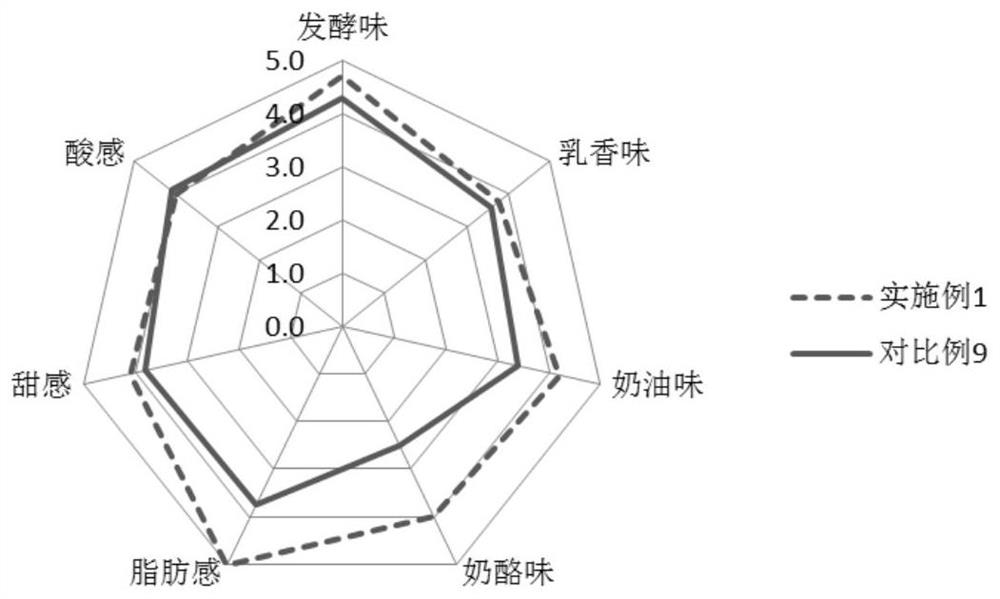

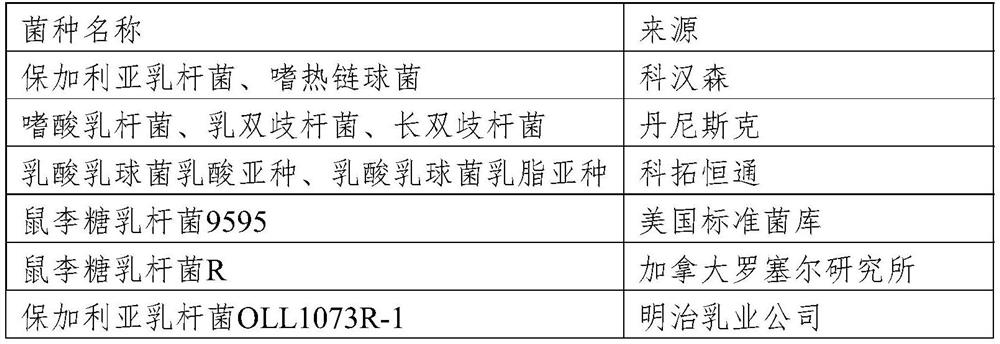

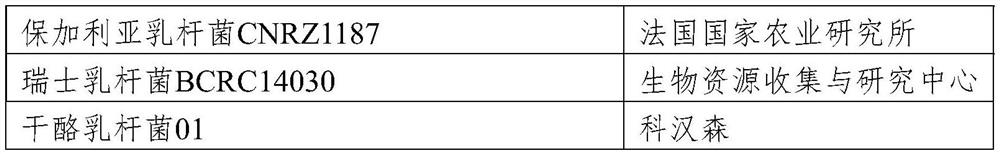

[0062] See Table 1 for the source of strains used

[0063] Table 1

[0064]

[0065]

Embodiment 1

[0067] This embodiment provides a sucrose-free fermented milk of the present invention and a preparation method thereof. details as follows:

[0068] 1. Raw materials

[0069] (1) Preparation of fermented milk 1 (in 1000 kilograms):

[0070] Concentrated raw milk with RO membrane: 838.18 kg

[0071] Whey protein powder: 6 kg

[0072] Hydroxypropyl distarch phosphate: 24 kg

[0073] Low-ester pectin: 3.6 kg

[0074] Inulin: 24 kg

[0075] Erythritol: 70 kg

[0076] Xylitol: 34 kg

[0077] Steviol glycosides: 0.22 kg

[0078] Strains: 1×10 11 CFU (ratio of strain activity, Streptococcus thermophilus:Lactobacillus bulgaricus=7:3);

[0079] (2) Preparation of fermented milk 2 (in 1000 kilograms):

[0080] Concentrated raw milk with RO membrane: 975 kg

[0081] Hydrolyzed whey protein powder: 12.5 kg

[0082] Yacon powder: 12.5 kg

[0083] Strains: 1×10 11 CFU (strain activity ratio, Lactococcus lactis subsp. lactis: Lactococcus lactis subsp. cremoris: Lactobacillus ...

Embodiment 2

[0094] This embodiment provides a sucrose-free fermented milk of the present invention and a preparation method thereof. details as follows:

[0095] 1. Raw materials

[0096] (1) Preparation of fermented milk 1 (in 1000 kilograms):

[0097] Concentrated raw milk with RO membrane: 846.08 kg

[0098] Whey protein powder: 6 kg

[0099] Hydroxypropyl distarch phosphate: 20 kg

[0100] Low-ester pectin: 3.6 kg

[0101] Inulin: 24 kg

[0102] Erythritol: 60 kg

[0103] Xylitol: 40kg

[0104] Mogroside: 0.16 kg

[0105] Glucosyl steviol glycosides: 0.16 kg

[0106] Strains: 1×10 11 CFU (ratio of strain activity, Streptococcus thermophilus:Lactobacillus bulgaricus=7:3);

[0107] (2) Preparation of fermented milk 2 (in 1000 kilograms):

[0108] Concentrated raw milk with RO membrane: 972.5 kg

[0109] Hydrolyzed whey protein powder: 12.5 kg

[0110] Yacon powder: 15kg

[0111] Strains: 1×10 11 CFU (ratio of strain activity, Lactococcus lactis subspecies lactic acid: Lact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com