Manufacturing method of transparent self-cleaning PMMA plate and transparent self-cleaning PMMA plate

A manufacturing method and self-cleaning technology, applied in the field of PMMA materials, can solve problems such as functional failure, aesthetic impact, and structural damage, and achieve the effect of improving interlayer bonding, ensuring reliability and durability, and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention provides a kind of manufacturing method of transparent self-cleaning PMMA sheet material and transparent self-cleaning PMMA sheet material, and this manufacturing method comprises steps:

[0024] (1) Manufacturing a mold having a cavity. The mold is a pouring glass mold, and its manufacturing process is detailed in the patents "Mold for Rapid Polymer Casting" (ZL 202120435162.3) and "Fastening Mechanism for Polymer Casting Mold and Polymer Casting Device" (ZL 202120246569.1) Relevant descriptions will not be repeated here.

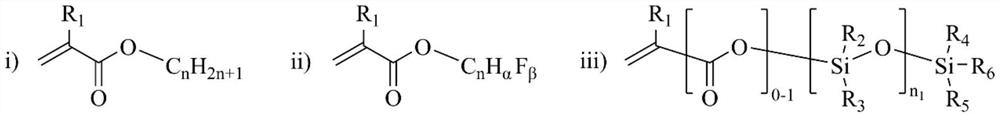

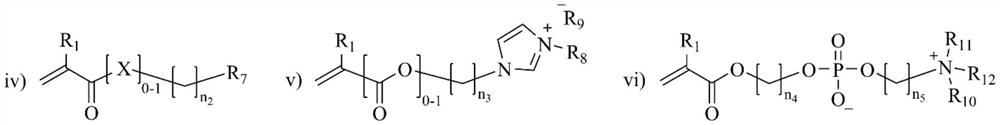

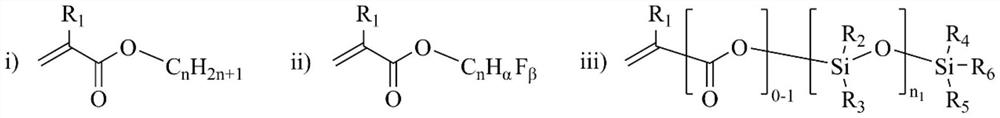

[0025] (2) Using one of vapor deposition, spin coating, dip coating, spray coating and flow coating, the functional solution is formed into a thin layer spreading liquid film on the side wall or both side walls of the cavity, and the functional solution Including functional monomer, solvent MMA, thickener and substrate wetting agent, the functional monomer has hydrophobic self-cleaning function or hydrophilic self-cleaning fun...

Embodiment 2

[0066] The difference with the manufacturing method of Example 1 is that in this embodiment, the manufacturing method of the transparent self-cleaning PMMA plate comprises the following steps:

[0067] Manufacture a glass mold for pouring molding, the average roughness of the inner wall surface of the cavity of the glass mold is 10nm;

[0068] Use hydrophobic self-cleaning functional monomers, specifically lauryl methacrylate and 1H,1H-perfluorooctyl methacrylate, with a molar ratio of 1:2, supplemented by suitable thickeners, substrate wetting agents and MMA solvents, Form a functional solution with a viscosity of 100210mPa s (25°C), a surface tension of ≤30mN / m, and a mass proportion of functional monomers of 70%. The mass proportions of the thickener and the substrate wetting agent in the functional solution are both 1 %;

[0069] The two walls of the mold cavity of the glass mold are pre-formed with the functional solution to form a thin layer of spreading liquid film, an...

Embodiment 3

[0073] The difference with the manufacturing method of Example 1 is that in this embodiment, the manufacturing method of the transparent self-cleaning PMMA plate comprises the following steps:

[0074] Manufacture a glass mold for pouring molding, the average roughness of the inner wall surface of the cavity of the glass mold is 400nm;

[0075] Use hydrophobic self-cleaning functional monomers, specifically octyl methacrylate, 1H, 1H, 2H, 2H-heptadecafluorodecyl acrylate and vinyl-terminated dimethyl polysiloxane (average molecular weight about 2000), molar Ratio 1:1:4, supplemented with suitable thickener, substrate wetting agent and MMA solvent, forming a function with a viscosity of 100210mPa s (25°C), surface tension ≤ 30mN / m, and functional monomer mass accounting for 70% Solution, the mass proportion of thickener and substrate wetting agent in the functional solution is 1%;

[0076] The two side walls of the mold cavity of the glass mold are pre-formed with the function...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com