Ceramic refractory cloth and preparation method thereof

A technology of refractory cloth and ceramicization, which is applied in the field of refractory materials, can solve the problems of ineffective protection treatment, no heat protection effect of refractory cloth, product damage, etc., to improve the ease of processing, convenient use, and excellent fit High performance, high installation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

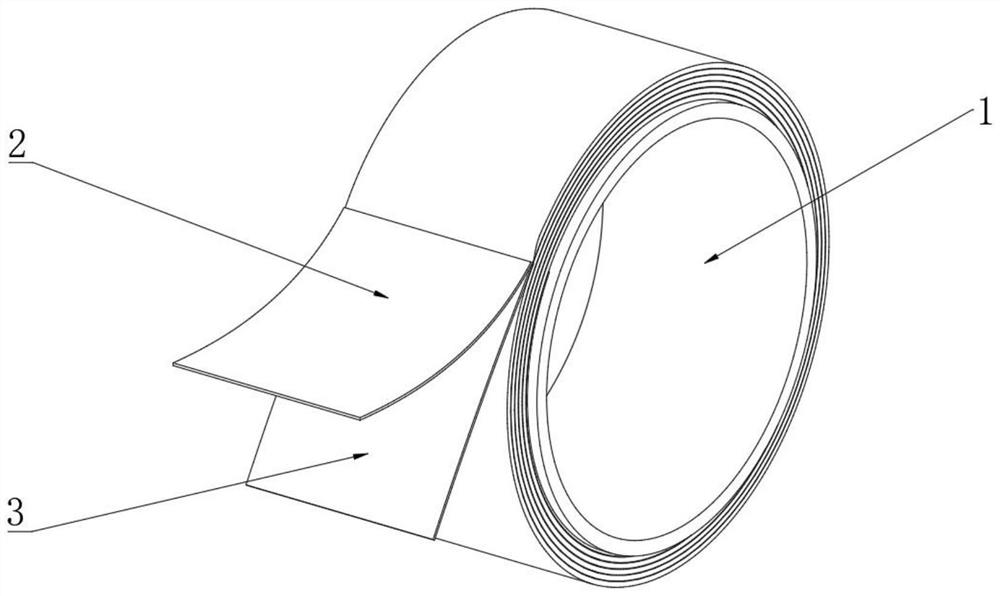

[0026] A ceramic refractory cloth, comprising a ceramic refractory cloth body 1, the ceramic refractory cloth body 1 is composed of an ultra-thin glass fiber layer 2 and a fireproof silicone rubber layer 3, and the ultra-thin glass fiber layer 2 is composed of the following Components in parts by weight: 16 parts of glass fiber, 4 parts of coupling agent, 10 parts of supplementary filler, 4 parts of defoaming powder, 4 parts of water-based polyurethane solvent, and the fireproof silicone rubber layer 3 is composed of the following parts by weight Composition: 8 parts of silicone polymer, 16 parts of rubber raw material, 4 parts of plasticizer, 10 parts of flame retardant supplementary filler.

[0027] The 8 parts of the organosilicon polymer is composed of the following components in parts by weight: 4 parts of the organosilicon silica gel, 2 parts of the catalyst, and 2 parts of the crosslinking agent.

[0028] At the same time, the invention also discloses a method for prepa...

Embodiment 2

[0039]A ceramic refractory cloth, comprising a ceramic refractory cloth body 1, the ceramic refractory cloth body 1 is composed of an ultra-thin glass fiber layer 2 and a fireproof silicone rubber layer 3, and the ultra-thin glass fiber layer 2 is composed of the following Components in parts by weight: 20 parts of glass fiber, 6 parts of coupling agent, 13 parts of supplementary filler, 6 parts of defoaming powder, 6 parts of water-based polyurethane solvent, and the fireproof silicone rubber layer 3 is composed of the following parts by weight: Composition: 10 parts of silicone polymer, 20 parts of rubber raw material, 6 parts of plasticizer, 13 parts of flame retardant supplementary filler.

[0040] 10 parts of organosilicon polymer consists of the following components in parts by weight: 5 parts of organosilicon silica gel, 3 parts of catalyst and 2 parts of crosslinking agent.

[0041] At the same time, the invention also discloses a method for preparing ceramic refractor...

Embodiment 3

[0052] A ceramic refractory cloth, comprising a ceramic refractory cloth body 1, the ceramic refractory cloth body 1 is composed of an ultra-thin glass fiber layer 2 and a fireproof silicone rubber layer 3, and the ultra-thin glass fiber layer 2 is composed of the following Components in parts by weight: 20 parts of glass fiber, 4 parts of coupling agent, 13 parts of supplementary filler, 4 parts of defoaming powder, 6 parts of water-based polyurethane solvent, and the fireproof silicone rubber layer 3 is composed of the following parts by weight: Composition: 8 parts of silicone polymer, 20 parts of rubber raw material, 4 parts of plasticizer, 13 parts of flame retardant supplementary filler.

[0053] The 8 parts of the organosilicon polymer consist of the following components in parts by weight: 4 parts of the organosilicon silica gel, 3 parts of the catalyst, and 1 part of the crosslinking agent.

[0054] At the same time, the invention also discloses a method for preparing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com