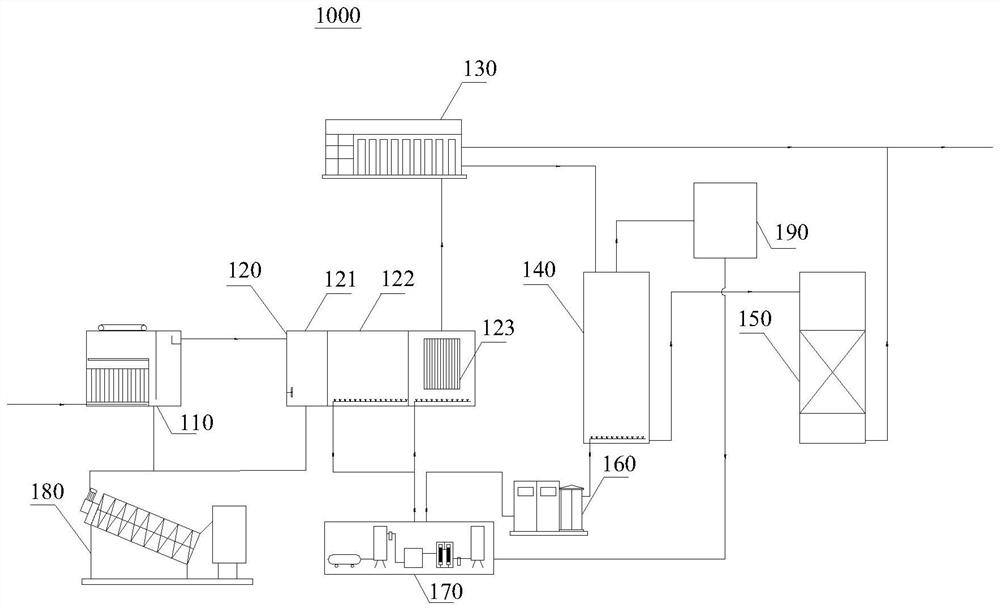

Full-amount treatment system and method for leachate of garbage transfer station

A technology of waste transfer station and treatment system, which is applied in the field of full-scale treatment system of high-difficulty organic wastewater, can solve the problems of large area, membrane concentrate to be treated, COD total nitrogen treatment not up to standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] The present embodiment is to the leachate of the garbage transfer station, wherein the water yield of the leachate of the garbage transfer station used is 5m 3 / d,, COD22630mg / L, TN 1254mg / L, NH 3 -N 757mg / L, SS 5228mg / L.

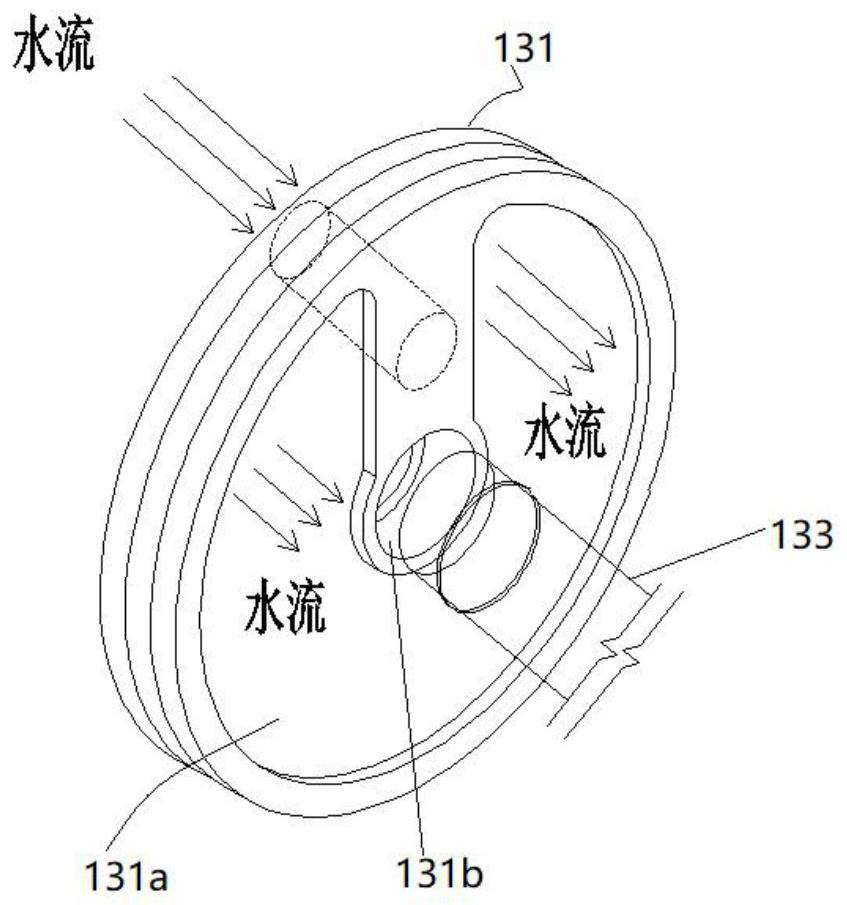

[0103] The landfill leachate first enters the electrocoagulation reaction tank with a voltage of 5.0V and a current density of 20mA / cm 2 , metal iron as the anode, metal titanium as the cathode, the distance between the plates is 2.5cm, the COD of the effluent is 15932mg / L, the removal rate is 29.6%, the SS is 1770mg / L, and the removal rate is 66.1%. Then the wastewater is transported to the MBR biochemical reactor, first into the anaerobic tank, and the DO concentration in the anaerobic tank is controlled to be about 0.4mg / L. Then it flows into the aerobic pool, the DO solubility is controlled at about 3mg / L, and the COD load is about 15kg / m 3 d, MLVSS is about 12000 mg / L or more. The biochemical system adopts a two-stage A / O-A / O method to stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com