Black toner for glass printing ink and preparation method thereof

A glass ink and black technology is applied in the field of black toner for glass ink and its preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a kind of preparation method of black toner for glass ink, comprising the following steps:

[0051] (1) Ingredients: mix the raw materials according to the ratio to obtain the mixed raw materials.

[0052] (2) Ball milling: Put the mixed raw materials into a ball mill for wet ball milling. After ball milling for 4-5 hours, a mixed slurry is obtained. The particle size D50 of the mixed slurry is 1.0-1.5 μm, and the D90 is 2.3-2.5 μm. In the ball milling step, the ball mill uses zirconia balls as the ball millstone, and the particle size of the zirconia balls is 8-12 mm. During the ball milling process, the mass ratio of zirconia balls, mixed raw materials and water is 3:(1-1.5):1 .

[0053] (3) Water washing: Put the mixed slurry into the storage tank, change the water after the mixed slurry settles, repeat the precipitation and change the water, and perform multiple water washing treatments. After the water washing step is completed...

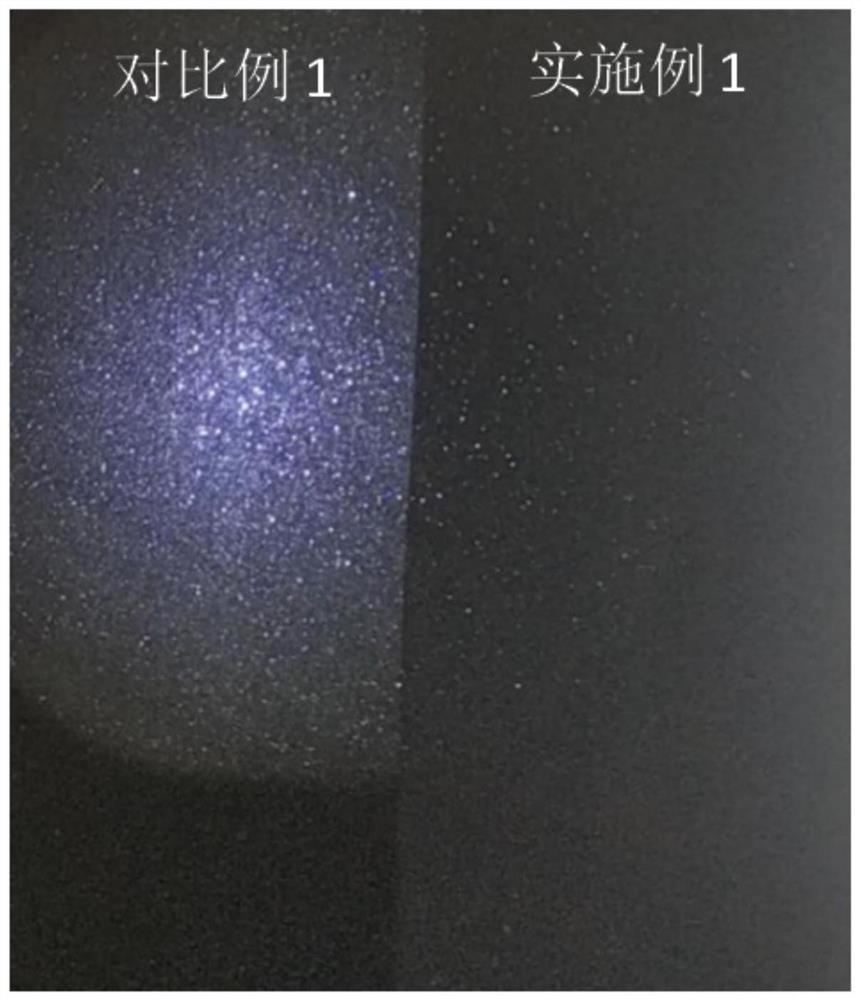

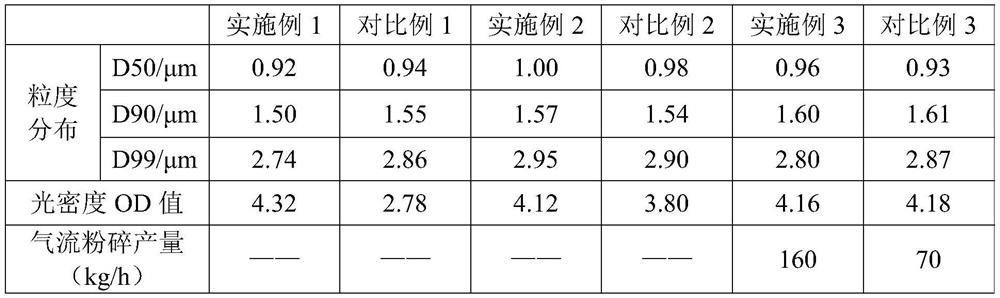

Embodiment 1

[0062] The black toner of the present embodiment is selected from the following components by mass percentage: copper oxide: 34%, chromium oxide: 63.8%, aluminum oxide: 1.5%, ammonium molybdate: 0.5%, bismuth oxide: 0.2% , wherein the average particle size of copper oxide is 3-5 μm, and the average particle size of aluminum oxide is less than or equal to 2 μm.

[0063] A preparation method of black toner for glass ink, comprising the following steps:

[0064] (1) The raw materials are mixed according to the proportion to obtain the mixed raw materials.

[0065] (2) Put the mixed raw material prepared in step (1) into a ball mill for wet ball milling, and after ball milling for 4 hours, a mixed slurry is obtained. The ball mill selects zirconia balls as the ball millstone, and the particle diameter of the zirconia balls is 8 to 12 mm. During the ball milling process, the mass ratio of zirconia balls, mixed raw materials and water is 3:1.2:1.

[0066] Detect the fineness of th...

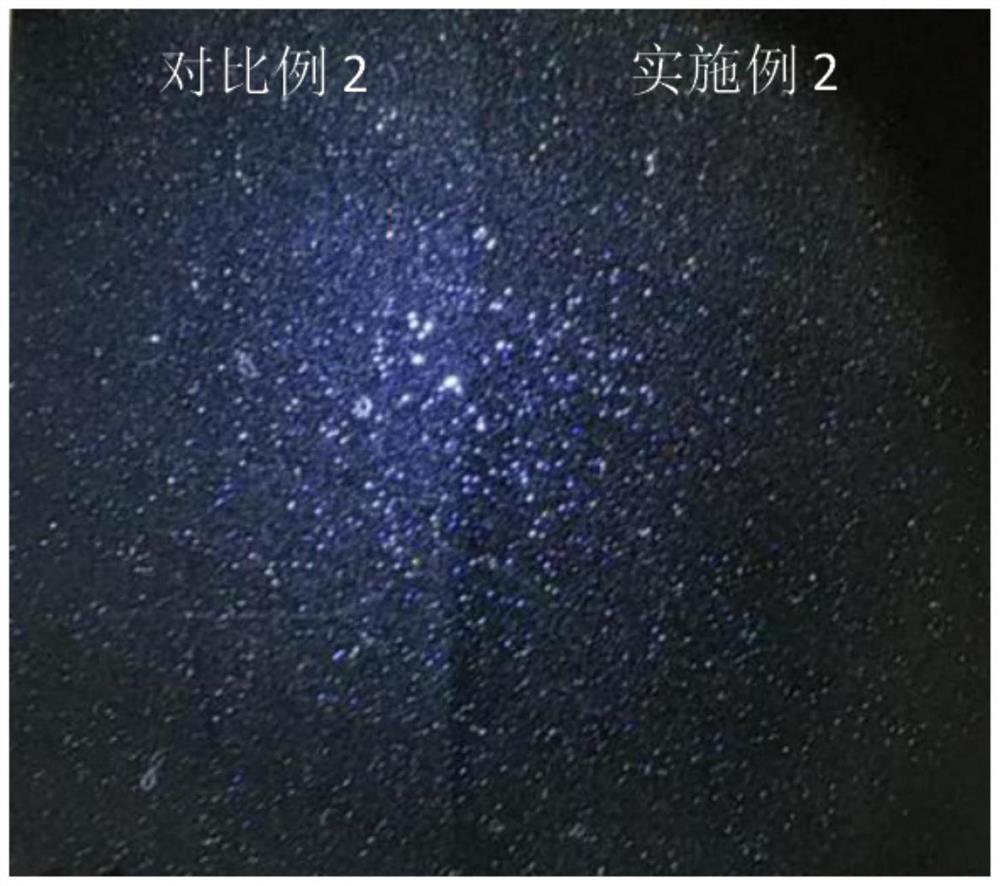

Embodiment 2

[0073] The black toner of this embodiment is selected from the following components by mass percentage: copper oxide: 36%, chromium oxide: 61.4%, aluminum oxide: 1.0%, ammonium molybdate: 1.2%, bismuth oxide: 0.4% , wherein the average particle size of copper oxide is 3-5 μm, and the average particle size of aluminum oxide is less than or equal to 2 μm.

[0074] A preparation method of black toner for glass ink, comprising the following steps:

[0075] (1) The raw materials are mixed according to the proportion to obtain the mixed raw materials.

[0076] (2) Put the mixed raw material prepared in step (1) into a ball mill for wet ball milling, and after ball milling for 5 hours, a mixed slurry is obtained. The ball mill selects zirconia balls as the ball millstone, and the particle diameter of the zirconia balls is 8 to 12 mm. During the ball milling process, the mass ratio of zirconia balls, mixed raw materials and water is 3:1.2:1.

[0077] Detect the fineness of the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com